Housing of electronic device and preparation method thereof

The technology of an electronic device and manufacturing method is applied in the directions of transportation and packaging, ion implantation plating, coating, etc., which can solve the problems of poor appearance attractiveness, inability to present a phantom pearlescent appearance, and difficulty in product competitiveness, and achieve Intense illusion pearlescent and metallic appearance, the effect of improving the attractiveness and competitiveness of the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

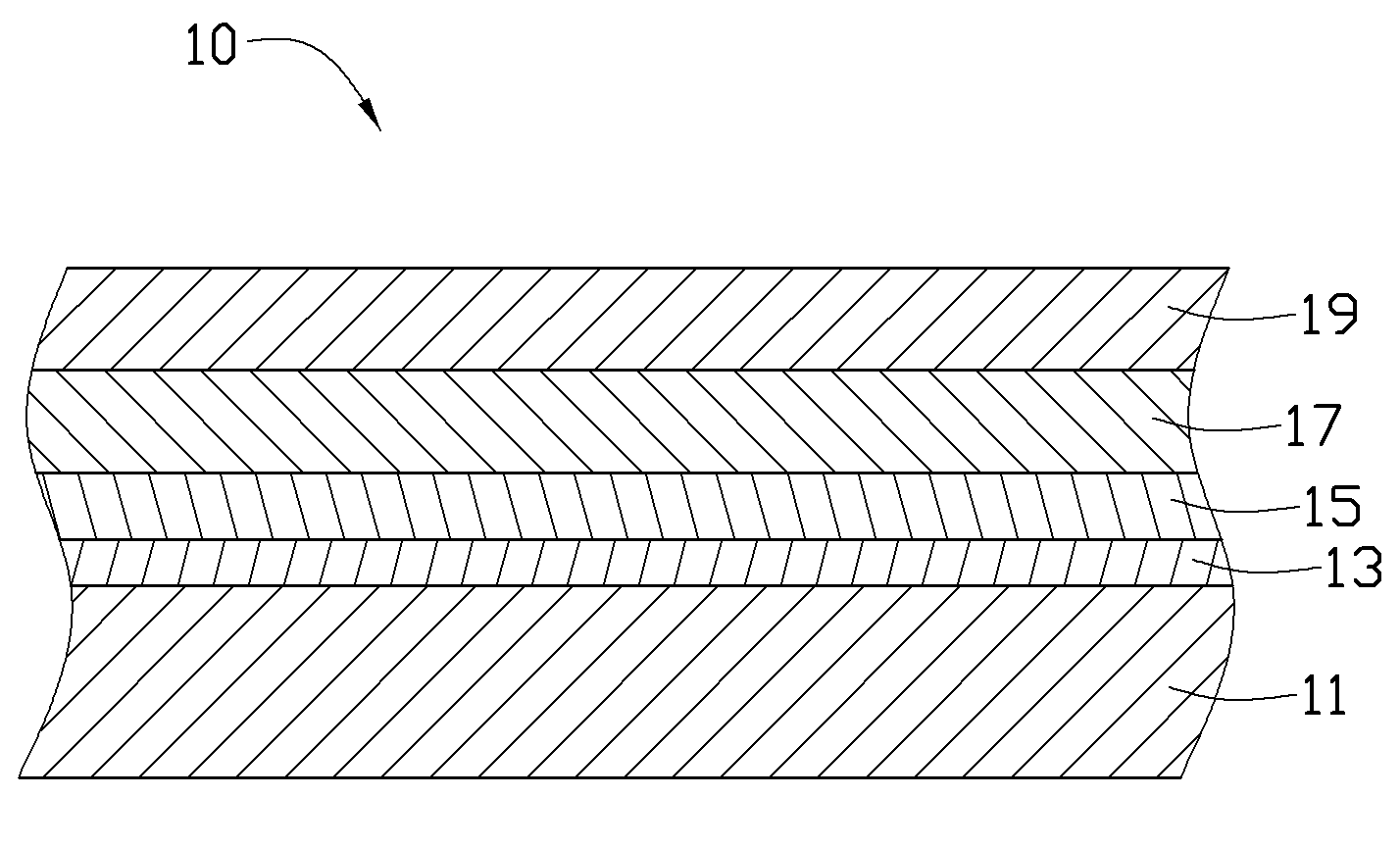

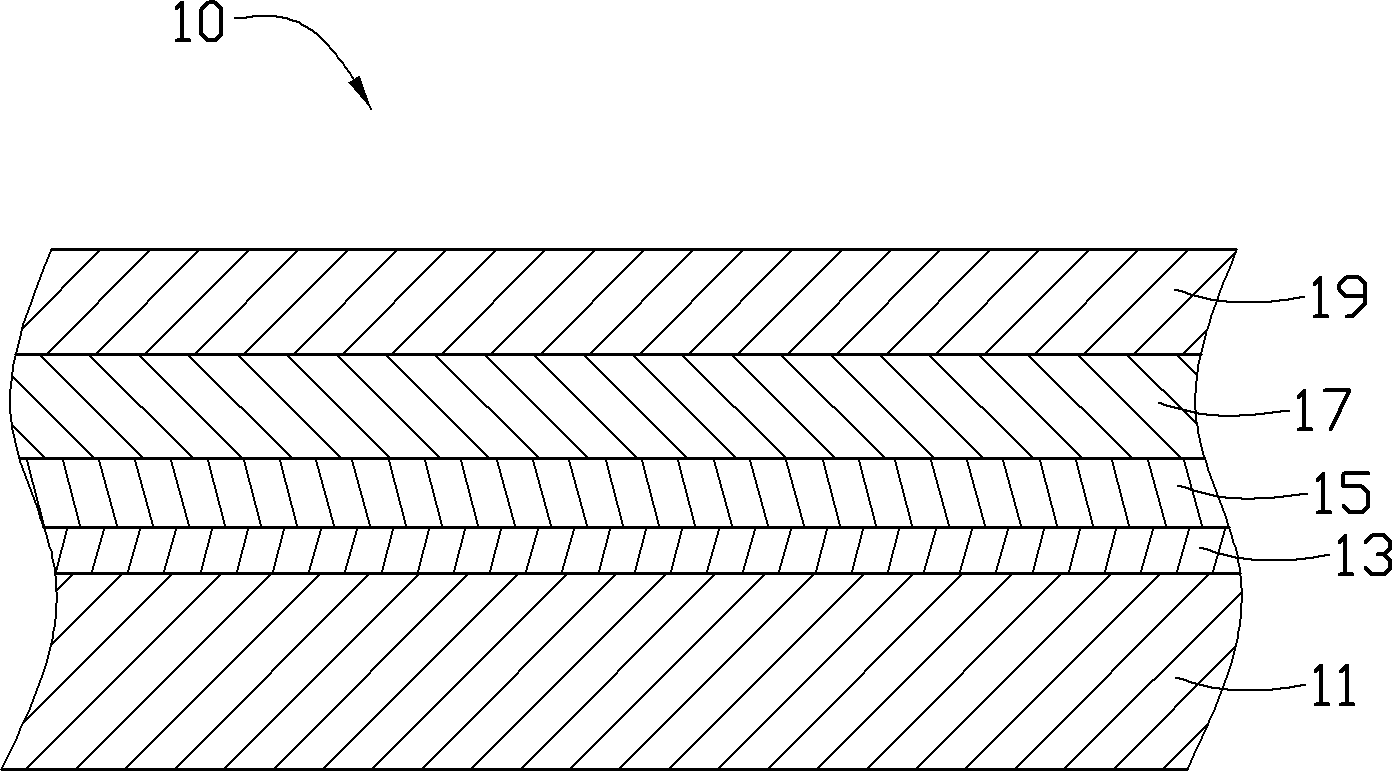

[0021] see figure 1 According to a preferred embodiment of the present invention, the housing 10 of the electronic device includes a base 11 and a primer layer 13 , a metal texture layer 15 , a middle paint layer 17 and a top paint layer 19 sequentially formed on the surface of the base 11 .

[0022] The base body 11 can be a plastic base body, which can be made by injection molding. The plastics for injection molding the matrix 11 can be selected from polycarbonate (PC), polyethylene (PE), polymethyl methacrylate (PMMA) and polycarbonate and acrylonitrile-styrene-butadiene copolymer. Any of the mixture (PC+ABS). The substrate 11 can also be a glass substrate or a ceramic substrate.

[0023] The primer layer 13 can be formed by spraying polyurethane paint on the surface of the substrate 11 . The primer layer 13 is a colorless and transparent paint layer, which has a smooth and even surface, which can enhance the bonding force between subsequent coatings and the primer layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com