Macromolecular composite cushion layer and preparation method of macromolecular composite cushion layer

A composite cushion and polymer technology, applied in layered products, chemical instruments and methods, synthetic resin layered products, etc., can solve problems such as functional defects and pollution, and achieve convenient construction, good stability, and sticking effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

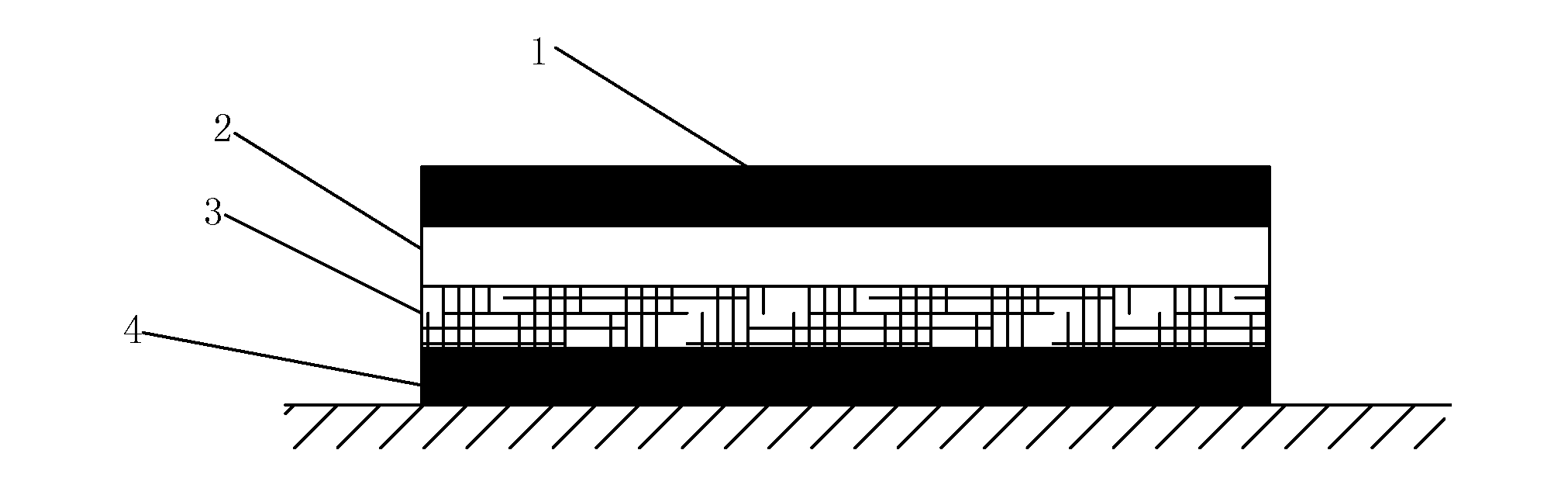

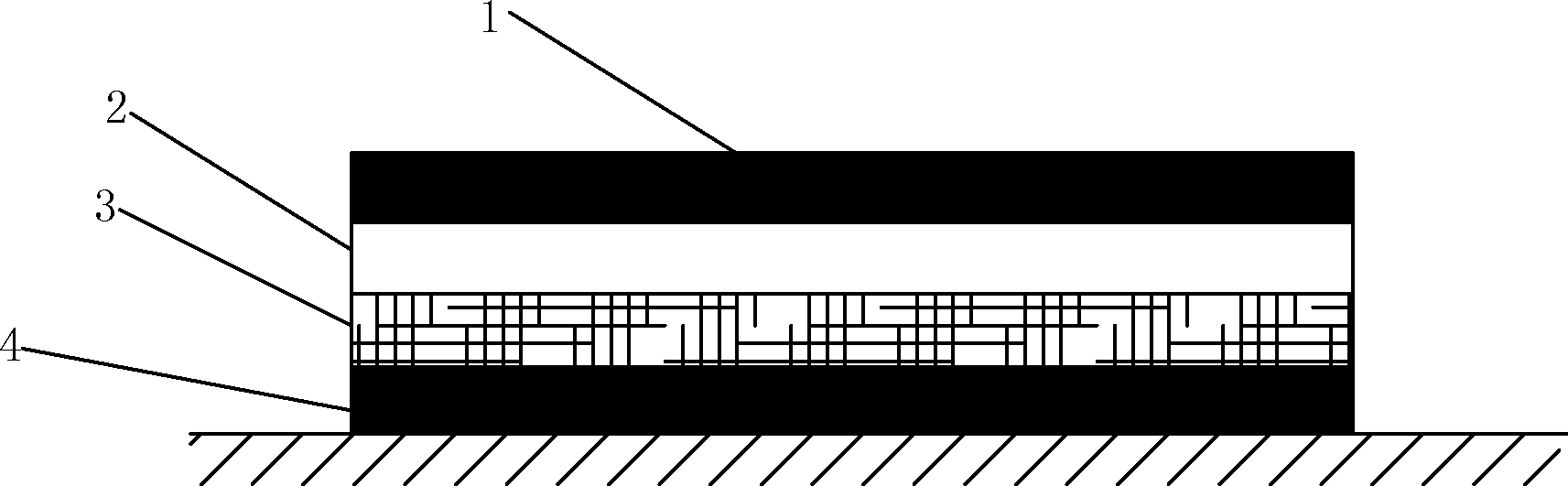

[0025] A polymer composite cushion, including PP non-woven fabric 1, a coating layer 2 blended with PP material and PE material, and PP woven fabric 3, which are sequentially combined, and a layer is arranged on the PP woven fabric by hot oil spraying Anti-skid layer4. The anti-slip layer 4 includes 50 parts of PE, 35 parts of PP / PE / EVA blend and 15 parts of PIB / PE blend in parts by mass. The 35 parts of PP / PE / EVA blended materials include, by mass parts, 15 parts of PP, 5 parts of PE and 15 parts of EVA. The 15 parts of PIB / PE blended material, by mass parts, include 10 parts of PIB, 4 parts of PE and 1 part of dispersant.

[0026] A preparation method of a polymer composite cushion, comprising the steps of:

[0027] ① Draw and weave the PP material to form PP woven fabric;

[0028] ②Heat setting of PP woven fabric;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com