Transverse shock absorber for locomotives

A lateral shock absorber, vehicle technology, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of leakage, inconvenient adjustment of guide seat processing and damping force, and poor workmanship, and achieve simplification. Good structure and assembly manufacturability, good damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

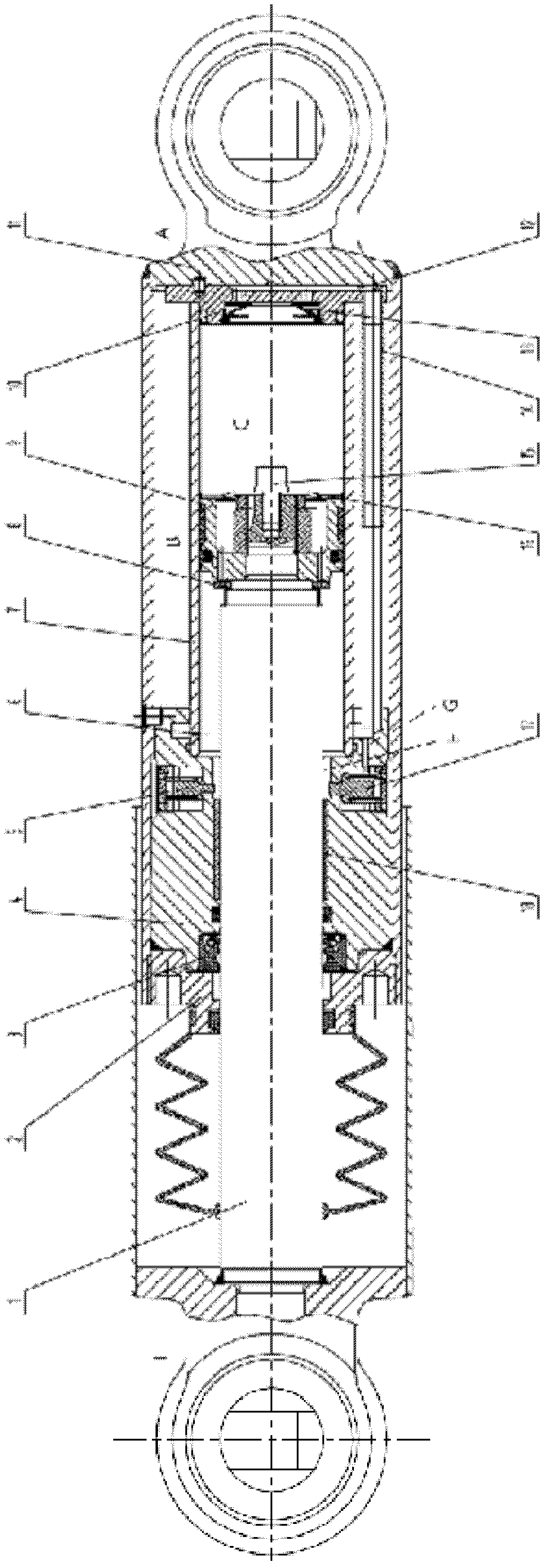

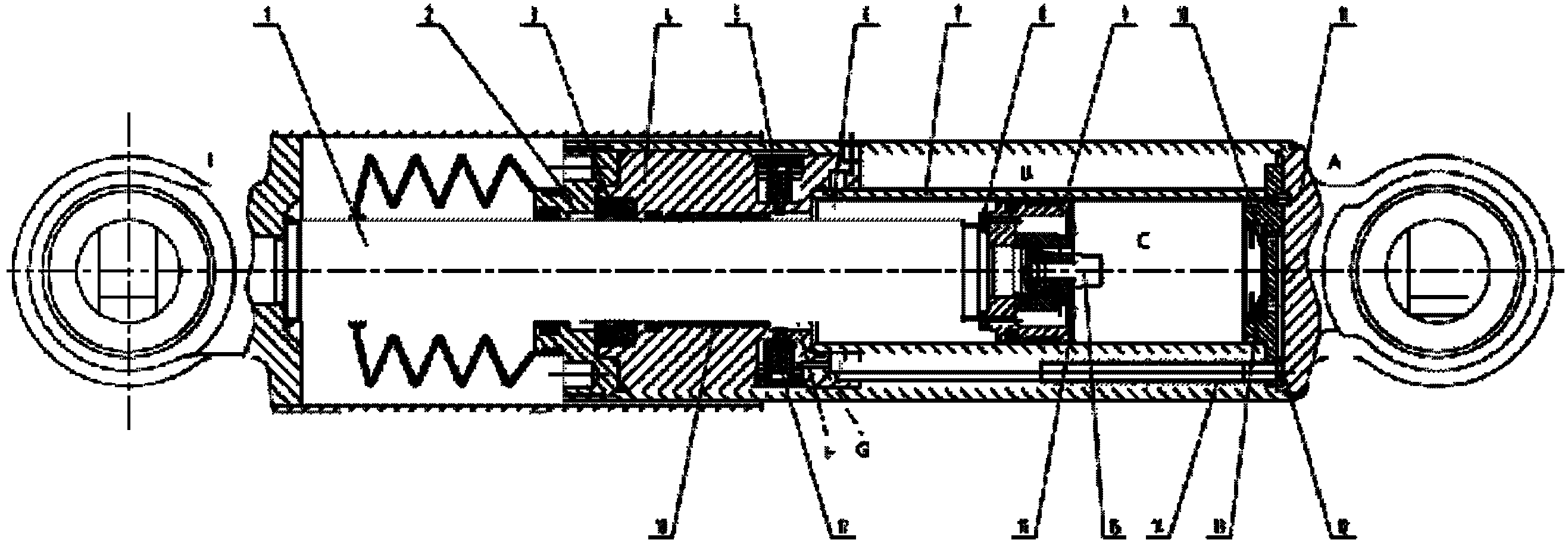

[0014] The lateral shock absorber for rolling stock of this embodiment, as shown in the drawings, includes a pressure cylinder 7 fixedly installed in the installation end A of the oil storage cylinder 11 through a bottom valve 10, and an oil return is formed between the oil storage cylinder 11 and the pressure cylinder 7. Cavity B. A piston 9 is housed in the pressure cylinder 7 . The piston rod 1 of the piston 9 protrudes from the other end of the oil storage cylinder 11 away from the installation end A, and is fixedly connected with the other installation end E equipped with a dust-proof cylinder. The piston 9 protrudes into the pressure cylinder 7 and is in sliding and sealing connection with it, and a cavity C away from the end cover is formed between the right end surface of the piston 9 and the bottom valve 10 .

[0015] The other end of the oil storage cylinder 11 is fixedly equipped with an end cap 4 in which the inner hole and the piston rod 1 are in sealing and dyna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com