Light emitting device

A technology for light-emitting devices and optical devices, which is applied in the directions of lighting devices, lighting device parts, and light source fixing, etc., can solve the problem of difficult cost, service life and safety factor control, inability to achieve 360° optical distribution, and limiting the brightness of lamps and lanterns. structure and other problems, to achieve the effect of improving luminous brightness, low driving voltage, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

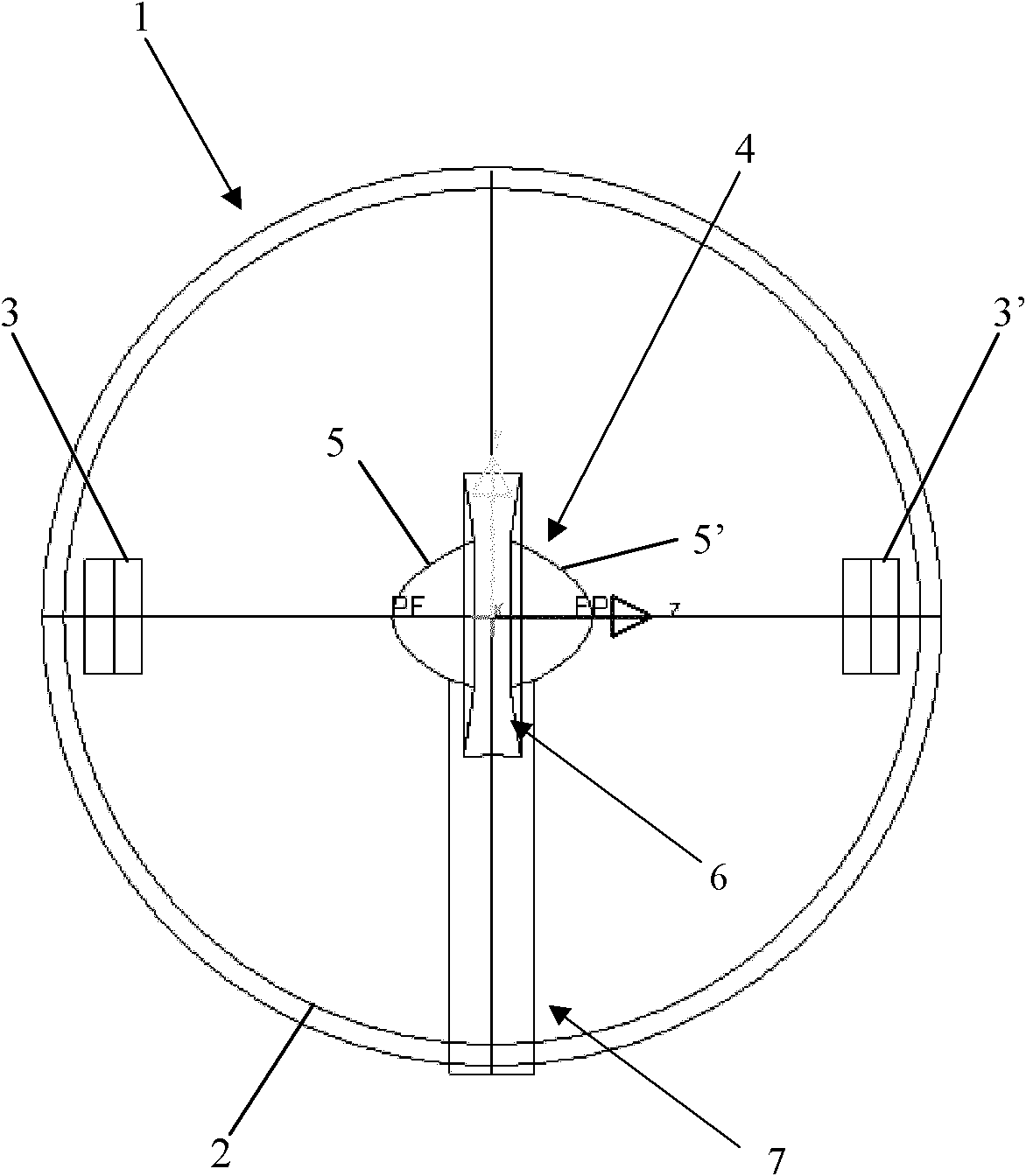

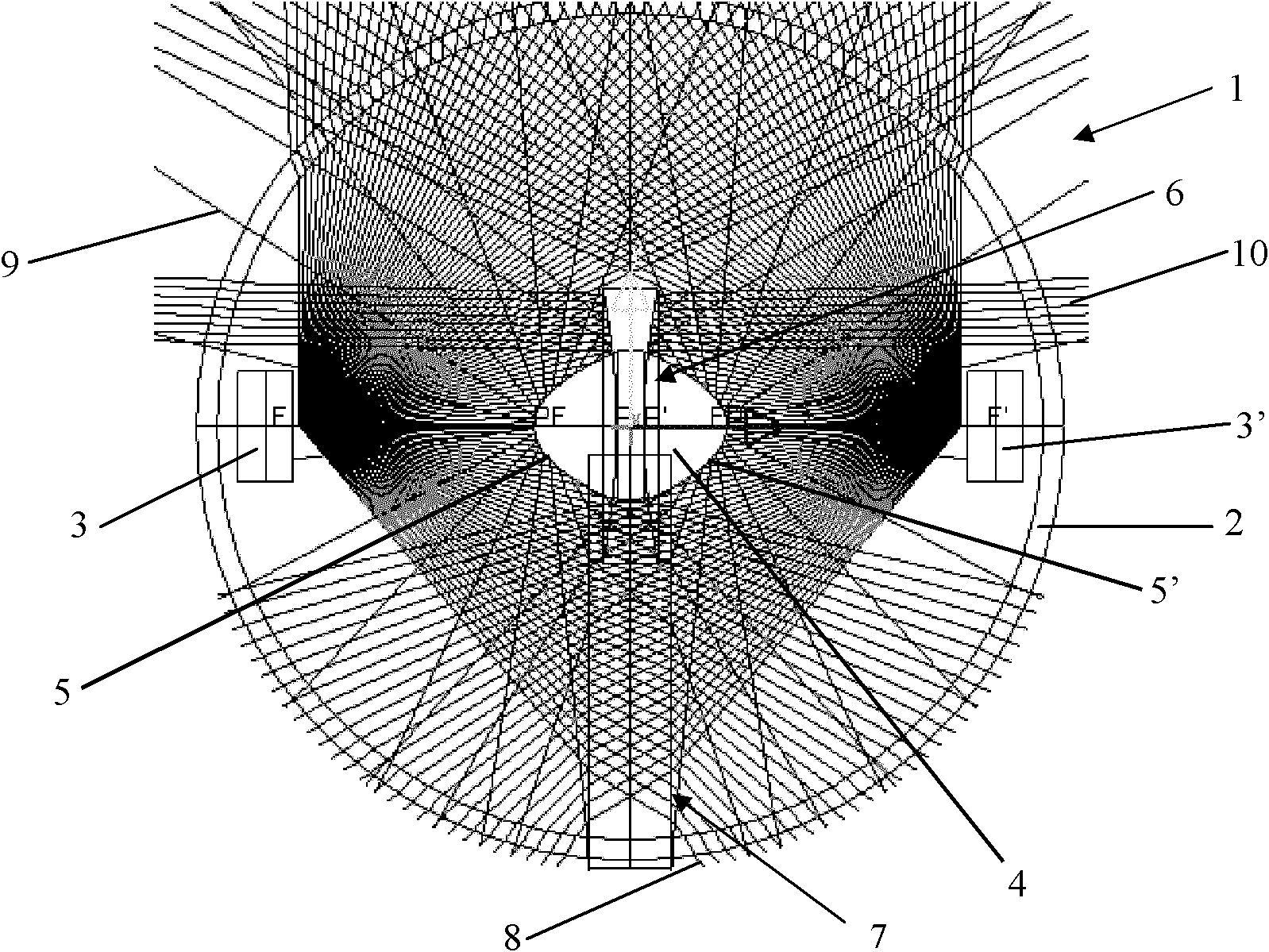

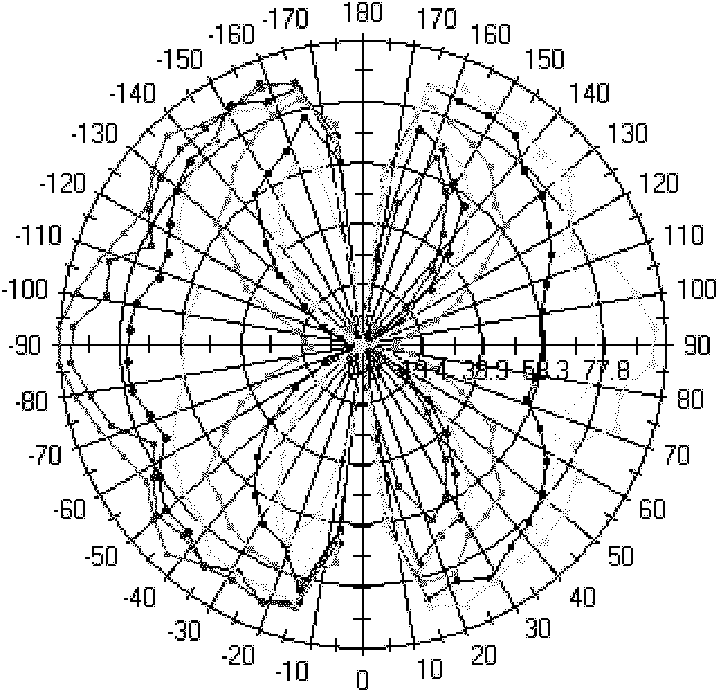

[0023] figure 1 A front view of a lighting device 1 according to the present invention is shown, which includes a lamp housing 2, a pair of light sources 3 and 3' and an optical device such as a reflector 4 mounted on an optical device holder 7. At least one reflector 4 arranged between the paired light sources 3, 3' is designed corresponding to the paired light sources 3, 3' to adjust, for example, reflect the direction of part of the light beams from the light sources 3, 3', to achieve the full beam direction It emits in all directions through the lamp housing 2 . In this embodiment, the light sources 3 and 3' are a pair of light sources that are centered on the reflector light 4 and are installed facing each other in the diameter direction of the spherical lamp housing 2, and the reflector 4 is located in the lamp housing 2 The position of the center of the ball. Here, the reflector 4 is formed from a first region and a second region. In the first area there are ellipsoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com