Ultrasonic atomizing device

An ultrasonic and capacitive technology, applied in ultrasonic humidifiers, heating methods, lighting and heating equipment, etc., can solve the problems of easy fouling of heaters, low safety factor, and non-dry burning, etc., and achieve high humidification and atomization efficiency and maintenance Simple, even humidification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

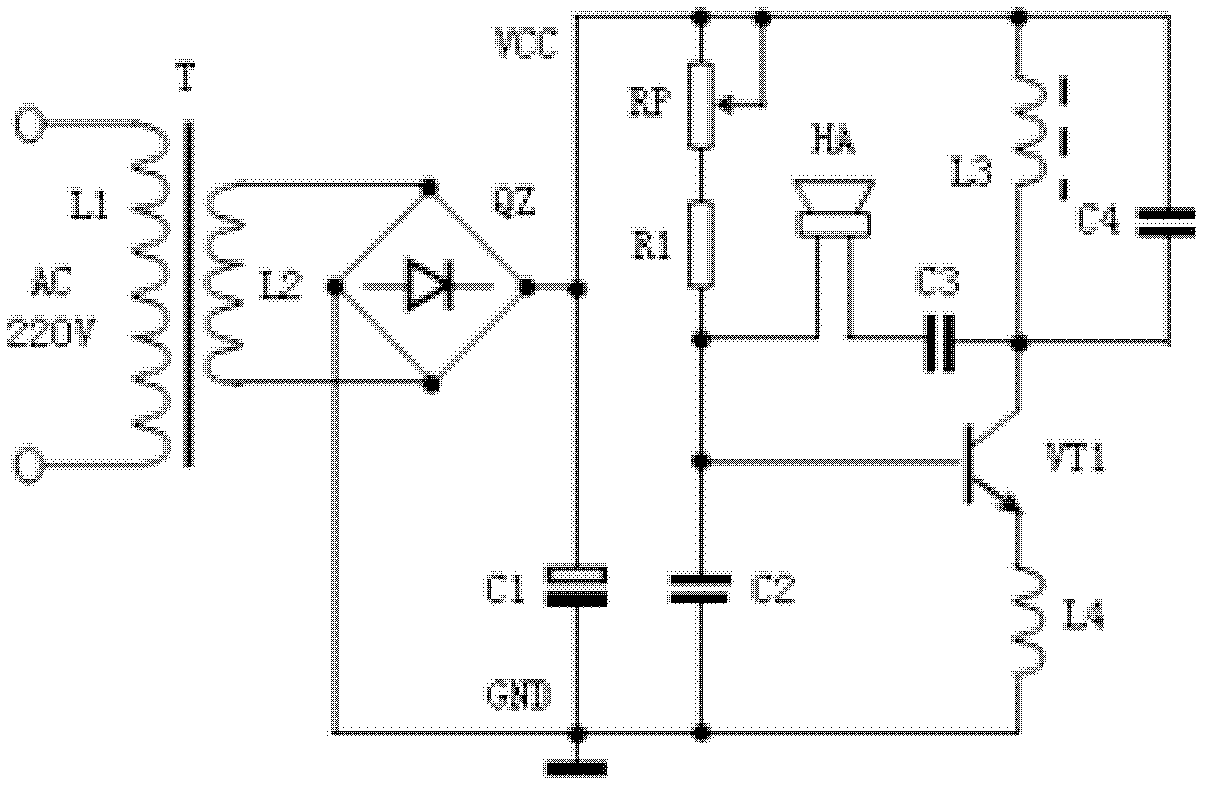

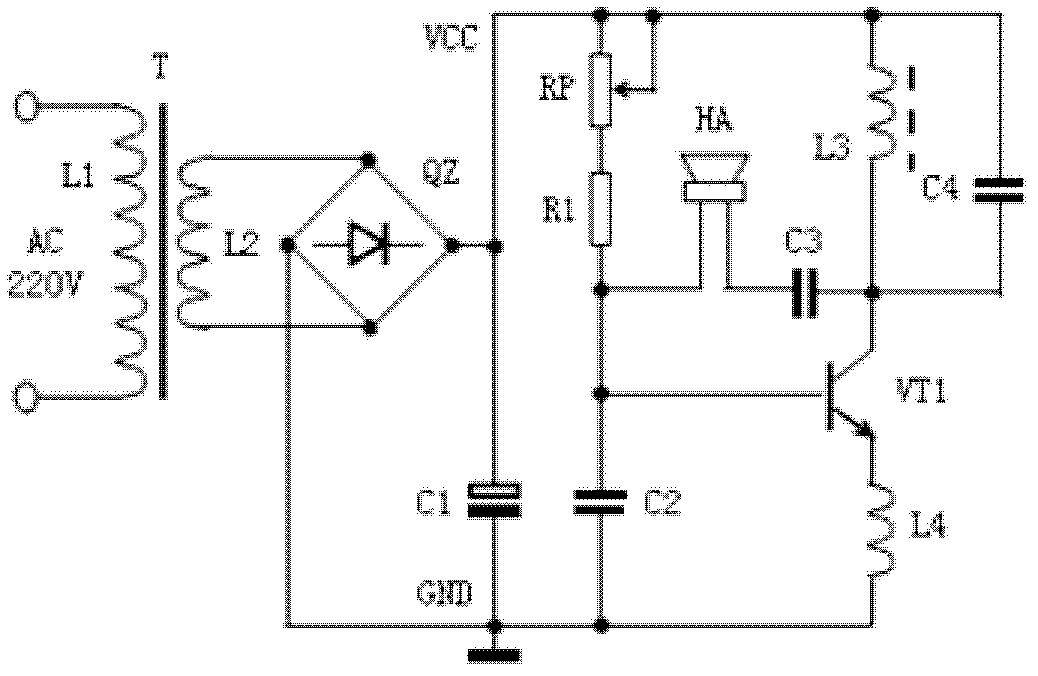

[0012] According to attached figure 1 The circuit working principle diagram and accompanying drawings of the ultrasonic atomization device shown are implemented according to the connection relationship between the components in each part of the circuit described in the summary of the invention, and the technical parameter requirements of the components described in the implementation mode. The present invention can be realized.

[0013] Selection of components and their technical parameters

[0014] VT1 is an NPN triode, the required power is 60W, the withstand voltage is greater than 300V, the model is 13009, plus a heat sink of appropriate size;

[0015] QZ is 4 silicon rectifier diodes of the full bridge rectifier circuit, the model is 1N5405;

[0016] R1 is a resistor with a resistance of 2KΩ and a power of 1W;

[0017] RP is the potentiometer, which is part of the bias resistor of the NPN transistor VT1, and its resistance is 3.3KΩ;

[0018] C1 is an electrolytic capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com