Humidifying device

The technology of a humidification device and a casing is applied in the field of atomizers, which can solve the problems of high use cost of pure water, uneconomical industrial application, hidden danger of power leakage, etc., and achieves the effects of low use cost, simple and reliable structure, and large humidification range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

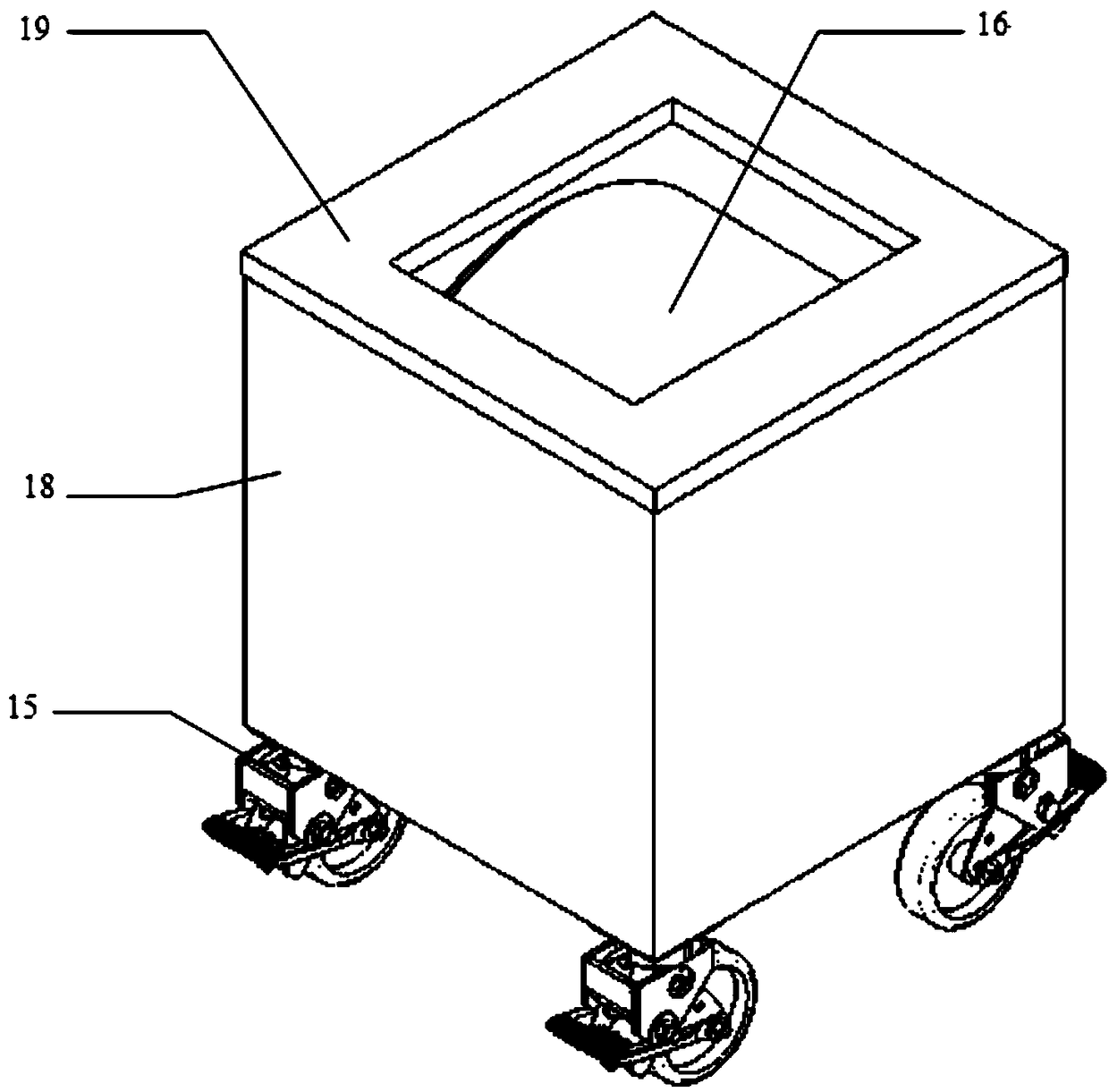

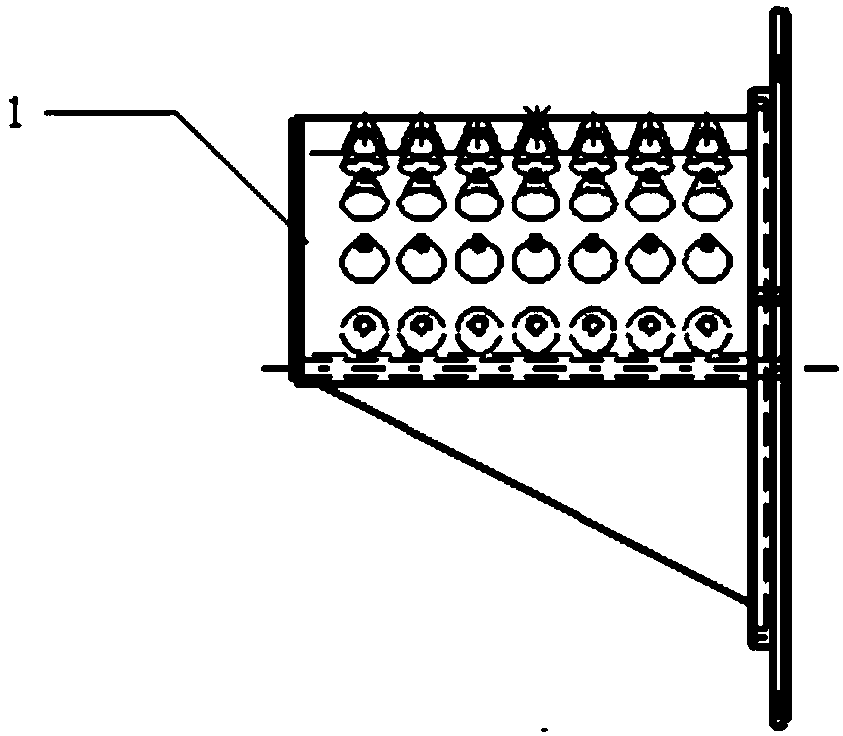

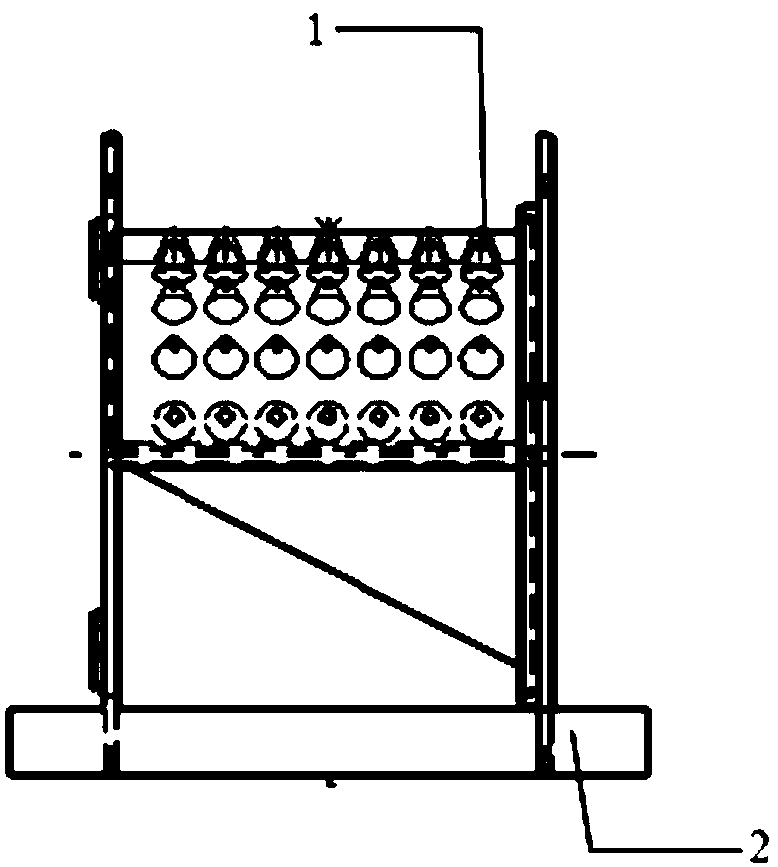

[0018] Such as Figure 1-8 As shown, a humidifying device includes a housing 18, a sponge support wheel 4, an air storage tank 1, an air pipe 9, and a control box 8; a glass water level visual tube 17 is hung on the outside of the housing 18, and a support wheel 15 is installed on the bottom. A cover plate 19 is provided with an opening. The air pipe 9 passes through the housing 18 and enters the interior of the housing 18. The cylinder body of the gas storage tank 1 is evenly distributed with inverted tapered air outlets. The sponge support wheel 4 is set on the gas storage tank 1. The surface is wound with a water-absorbing sponge body 16, and they are installed together in the inner shell support body 2. A limit adjustment ring 5 is provided at one end of the sponge support wheel 4, and an impeller 3 and a transmission key 14 are installed at the other end, and an air nozzle 10 is provided above the impeller 3. , tap water is injected from the opening of the cover plate 19,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com