A kind of special dispersion glass and its preparation method

A glass and dispersion technology, applied in the field of special dispersion glass and its preparation, can solve the problems of unfriendly environment and difficult control of optical uniformity, and achieve the effect of reducing erosion, avoiding clarification and homogenization, and improving optical uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

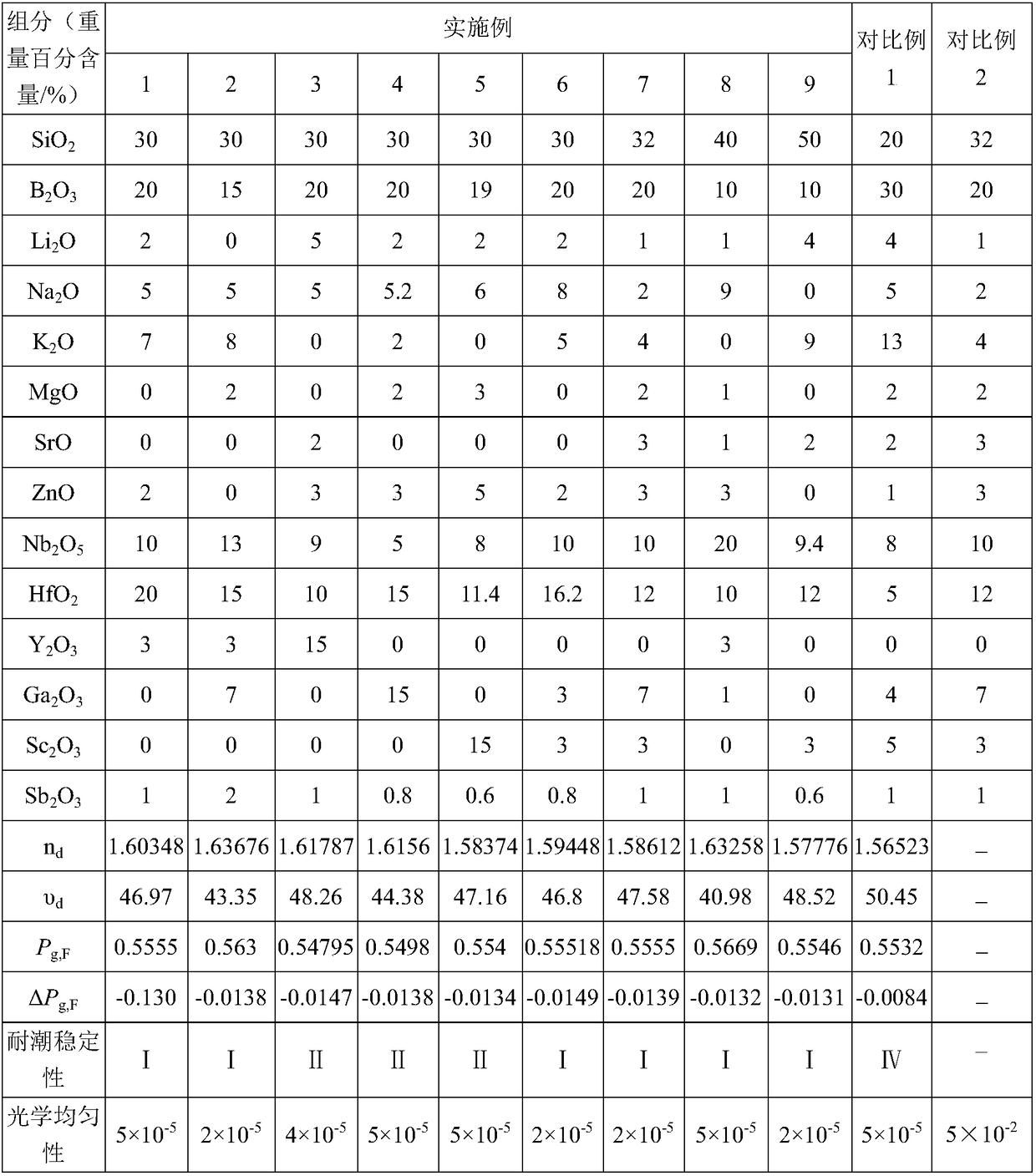

Examples

Embodiment 1

[0039] According to the glass composition in Table 1, take the raw material of corresponding weight, wherein Li 2 O, Na 2 O and K 2 The raw material corresponding to O is each oxide itself, the raw material corresponding to ZnO is its carbonate, and the raw material corresponding to Y is 2 o 3 The corresponding raw material is nitrate; after these raw materials are mixed evenly, the first step of melting is carried out in a quartz crucible to generate glass clinker, and then the glass clinker is poured on the calendering table, cooled and formed, crushed and then added In the strengthened Pt crucible, the second step of fine melting is carried out. The melting temperature of the first step is 1150°C and the melting time is 2h. The temperature of the second melting step is 1300°C and the melting time is 4h. , the strengthened Pt crucible is placed in the kiln; 10 minutes before feeding the strengthened Pt crucible, start to pass high-purity Ar into the strengthened Pt crucib...

Embodiment 2

[0041] According to the glass composition in Table 1, take the raw material of corresponding weight, wherein Na 2 O and K 2 The raw material corresponding to O is the corresponding carbonate, the raw material corresponding to MgO is the corresponding nitrate, and the Y 2 o 3 and Ga 2 o 3 The corresponding raw materials are the oxides themselves; after these raw materials are mixed evenly, the first step of melting is carried out in the quartz crucible to generate glass clinker, and then the glass clinker is poured on the calendering table, and after cooling, forming and crushing Put it into the strengthened Pt crucible for the second step of fine melting, in which the melting temperature of the first step is 1200 ° C, the melting time is 3 hours, the temperature of the second melting step is 1400 ° C, the melting time is 6 hours, and the second step is melting , the strengthened Pt crucible was placed in the furnace; 5 minutes before feeding into the strengthened Pt crucib...

Embodiment 3

[0043] According to the glass composition in Table 1, take the raw material of corresponding weight, wherein Li 2 O and Na 2 The raw materials corresponding to O are the corresponding nitrates, the raw materials corresponding to SrO and ZnO are the oxides themselves, and the Y 2 o 3 The corresponding raw material is carbonate; after these raw materials are mixed evenly, the first step of melting is carried out in the quartz crucible to generate glass clinker, and then the glass clinker is poured on the calendering table, and after cooling, forming and crushing Put it into the strengthened Pt crucible for the second step of fine melting, in which the melting temperature of the first step is 1150°C and the melting time is 2.5h, the melting temperature of the second step is 1350°C and the melting time is 5h, the second step When melting, the strengthened Pt crucible was placed in the furnace; 20 minutes before feeding into the strengthened Pt crucible, high-purity N was introdu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com