Coulomb efficiency measuring method used for SOC (system-on-chip) evaluation of power battery

A Coulombic efficiency and power battery technology, applied in the field of Coulombic efficiency measurement, can solve problems such as changes in Coulombic efficiency, inaccurate SOC estimation, and failure to consider the range of battery capacity, etc., and achieve the effects of easy operation, wide temperature application range, and fast calculation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

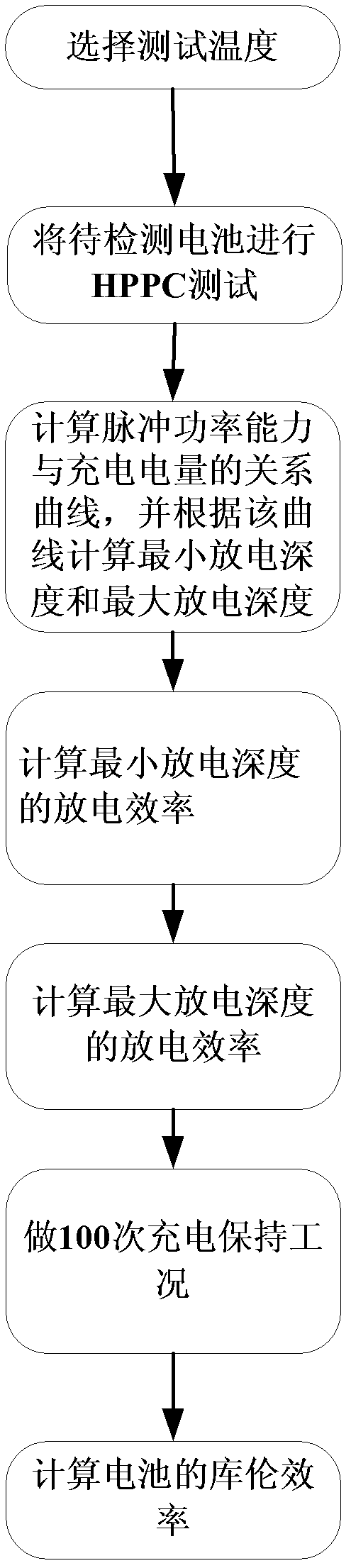

[0024] Specific implementation mode one: as figure 1 As shown, the Coulombic efficiency measurement of the power battery is carried out through the following steps:

[0025] Step 1: Select a power battery to be tested with an operating temperature range of -20°C-60°C, and select a temperature within this temperature range as the temperature to be tested. The following steps 2 to 7 are all carried out under the temperature conditions to be tested;

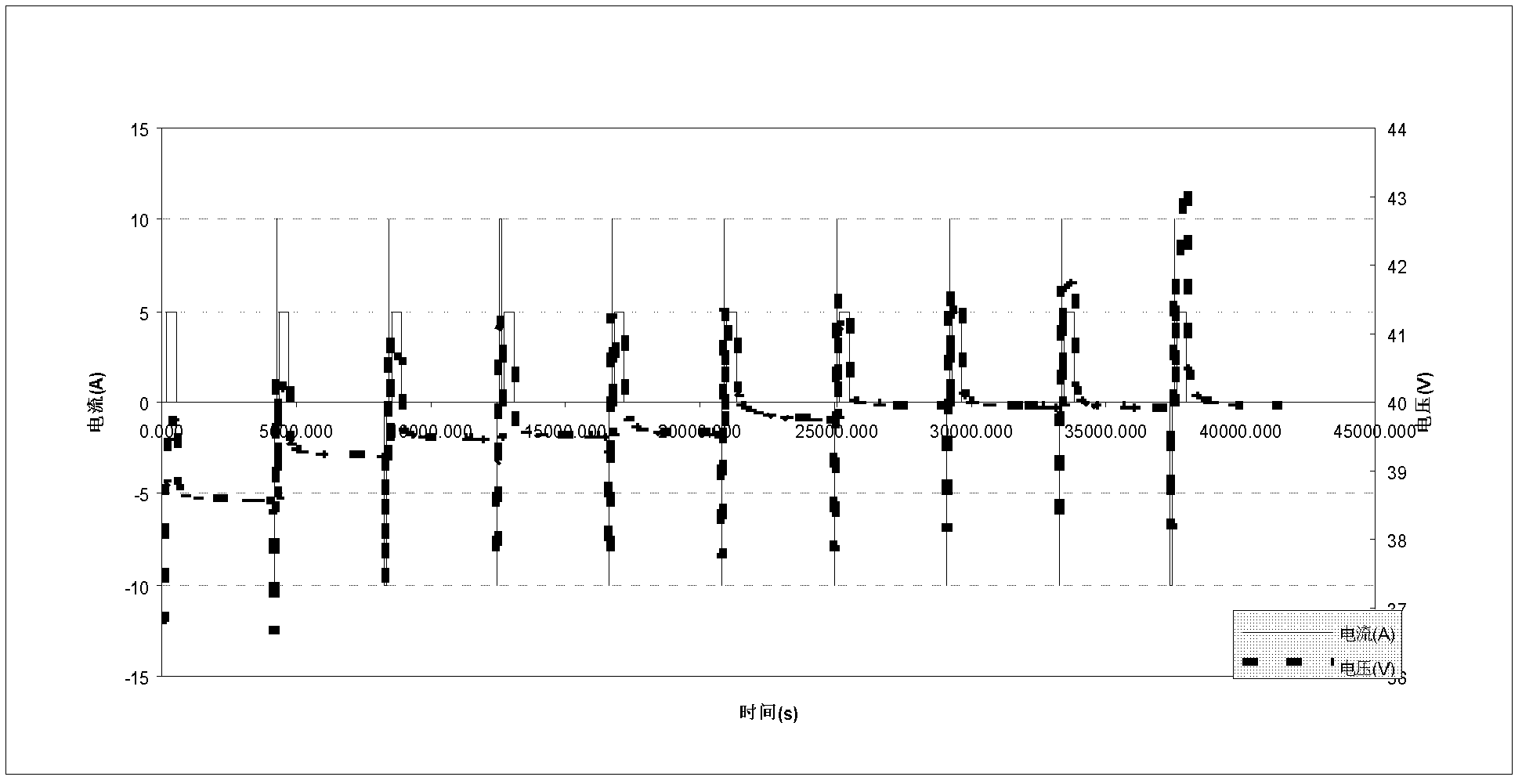

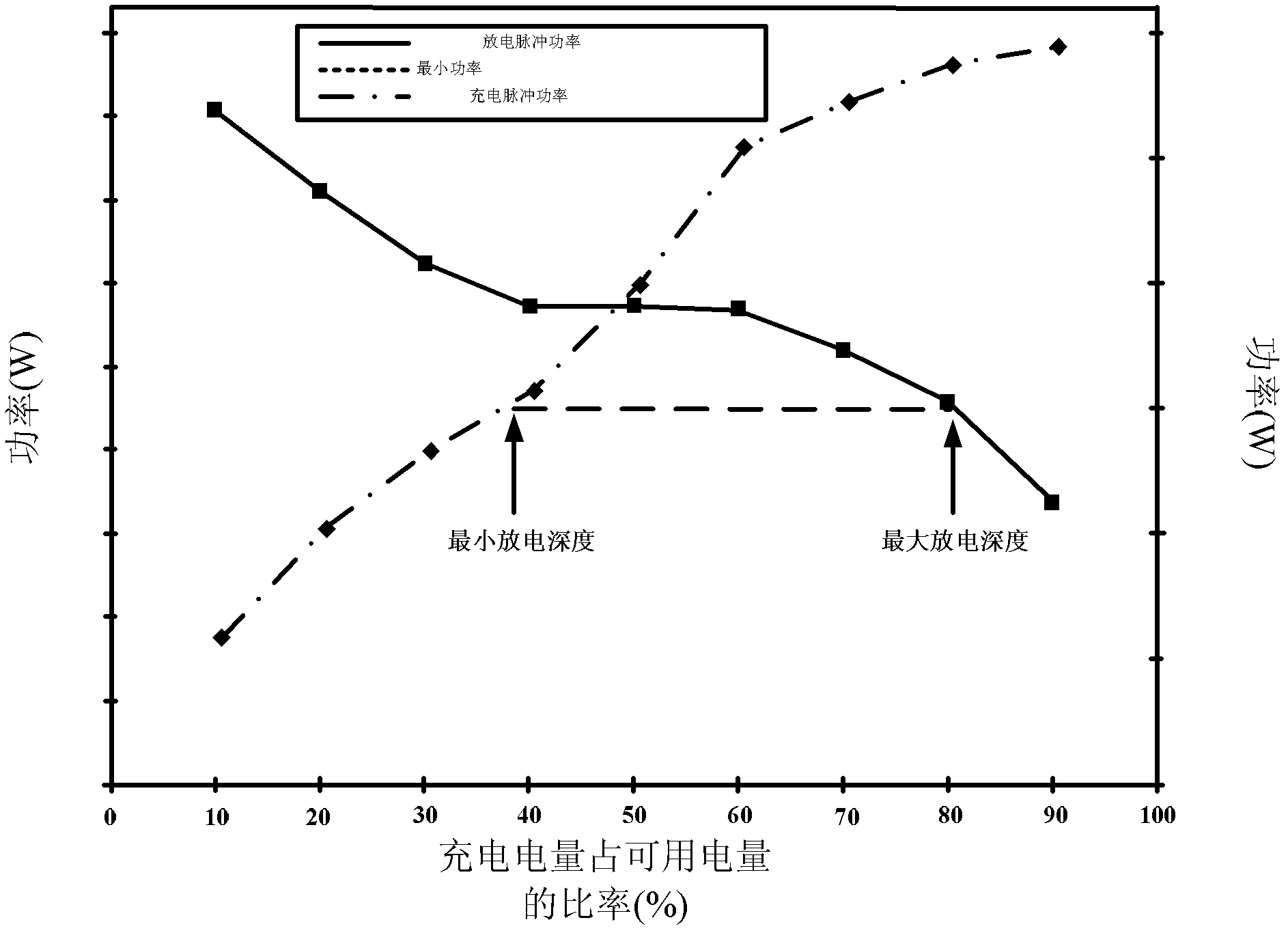

[0026] Step 2: Test the mixed power pulse characteristics of the battery to be tested, discharge the battery to be tested, let it rest for an hour, and charge the battery with a constant current that does not exceed the safe current to the m of the available battery power 1 %, then conduct a pulse power test, stand still for an hour, and then charge the battery with a constant current not exceeding the safe current until the power is the m of the available power of the battery 2 %, carry out the mixed power pulse characteristic tes...

specific Embodiment approach 2

[0034] Specific embodiment two: The Coulombic efficiency measurement is carried out on the power battery to be tested in specific embodiment one, and the measurement steps and results are as follows:

[0035] Step 1: Select a temperature of 20°C within the operating temperature range of the power battery to be tested as the temperature to be tested to determine the Coulombic efficiency;

[0036] Step 2: Conduct a mixed power pulse characteristic test on the battery to be tested, discharge the battery to be tested, let it rest for an hour, charge the battery with a constant current not exceeding the safe current to 10% of the battery’s available power, and then conduct a pulse power test , stand still for an hour, and then charge the battery with a constant current not exceeding the safe current until the power is 20% of the battery’s available power, and perform a mixed power pulse characteristic test, and so on, until the charging power is 90% of the battery’s available power,...

specific Embodiment approach 3

[0048] For the power battery to be tested in the second specific embodiment, in step 1, select a temperature of 30° C. within the working temperature range of the power battery to be tested as the temperature to be measured to measure the Coulombic efficiency, n=15 in step 6, other steps and specific implementation methods The two measures Coulombic efficiency in the same way.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com