Supercapacitor redox activated electrolyte

A supercapacitor and electrolyte technology, applied in the field of electrochemical energy storage, can solve the problems of poor cycle stability, low coulombic efficiency, and difficulty in practical application, and achieve the goal of ensuring coulombic efficiency and cycle stability and improving specific capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

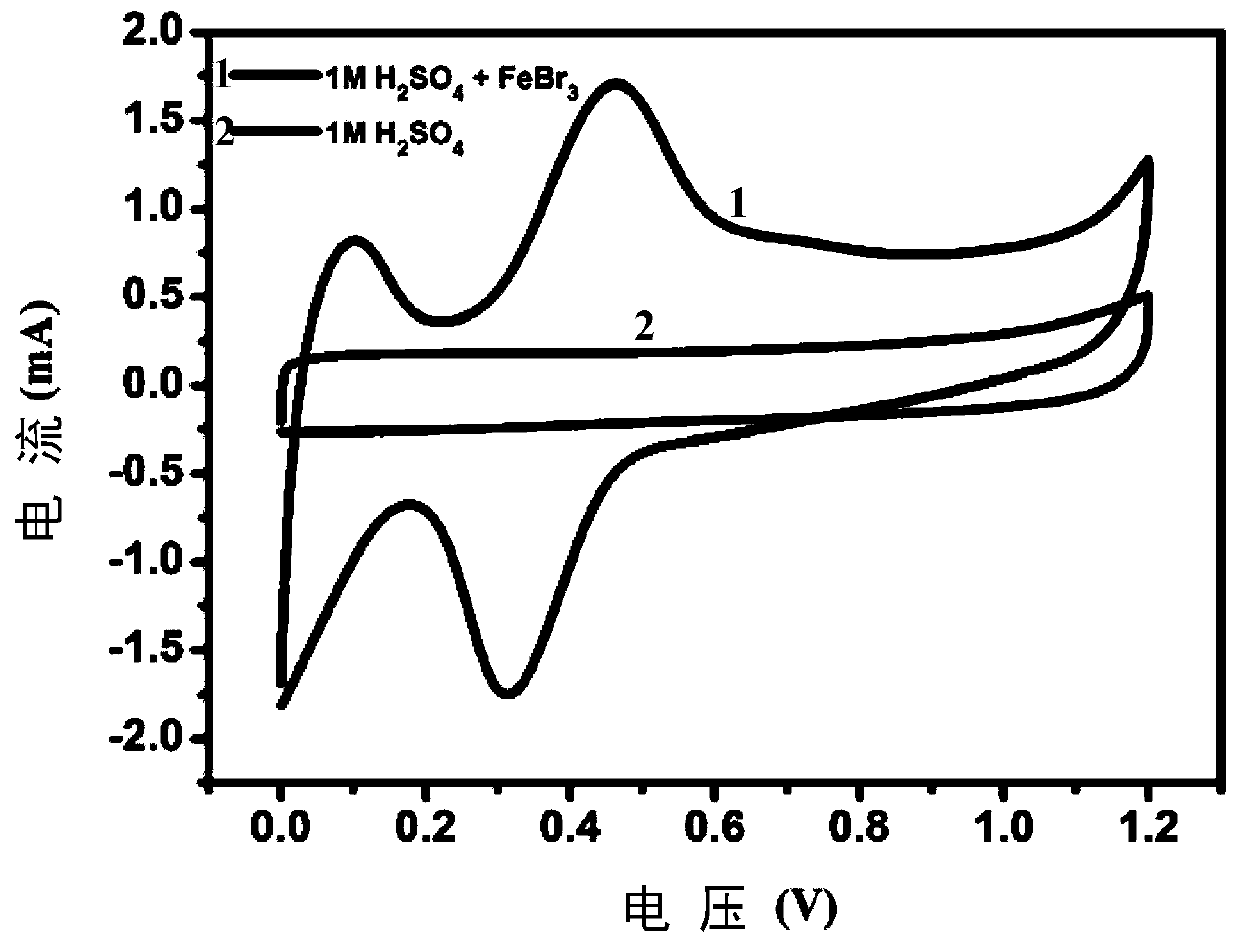

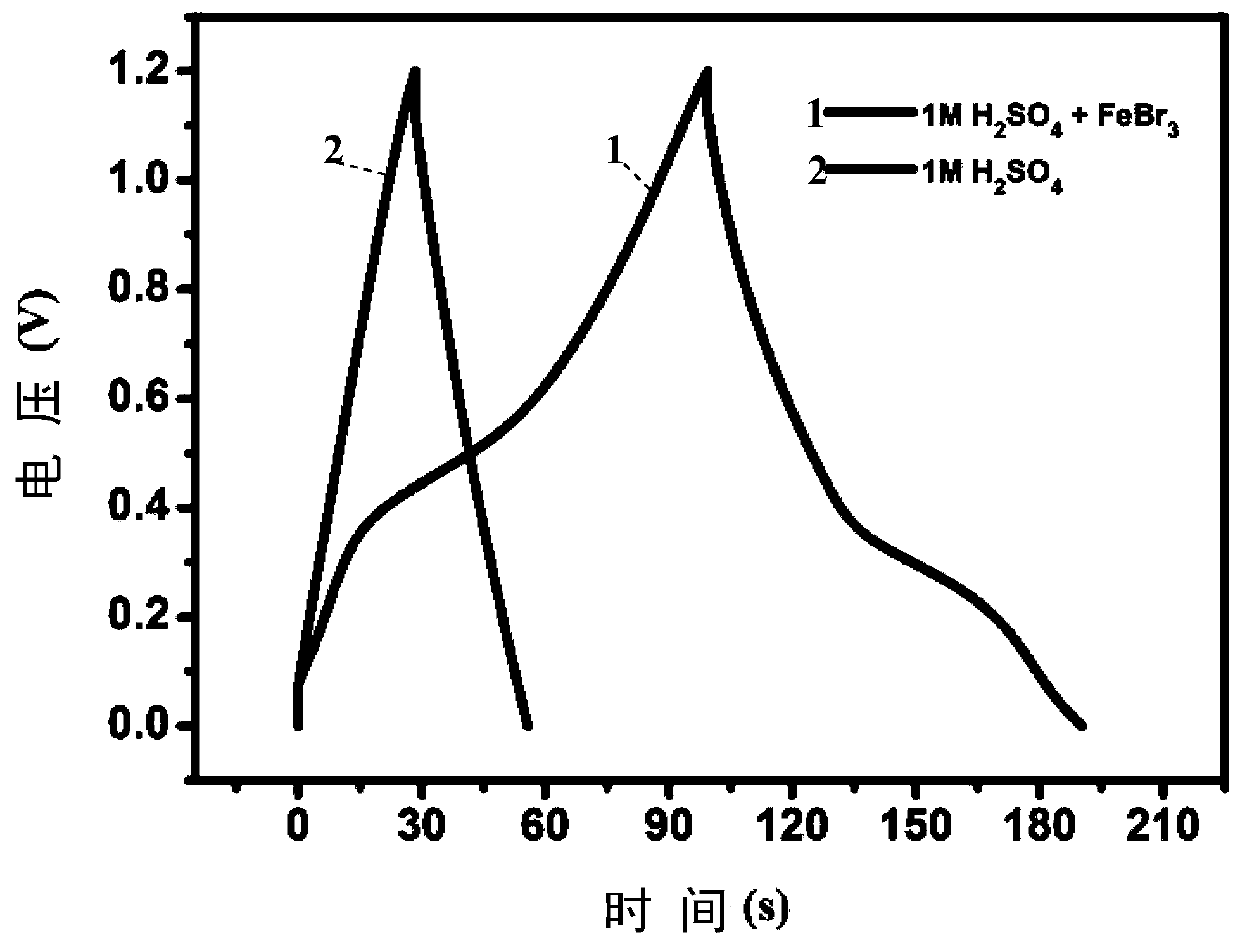

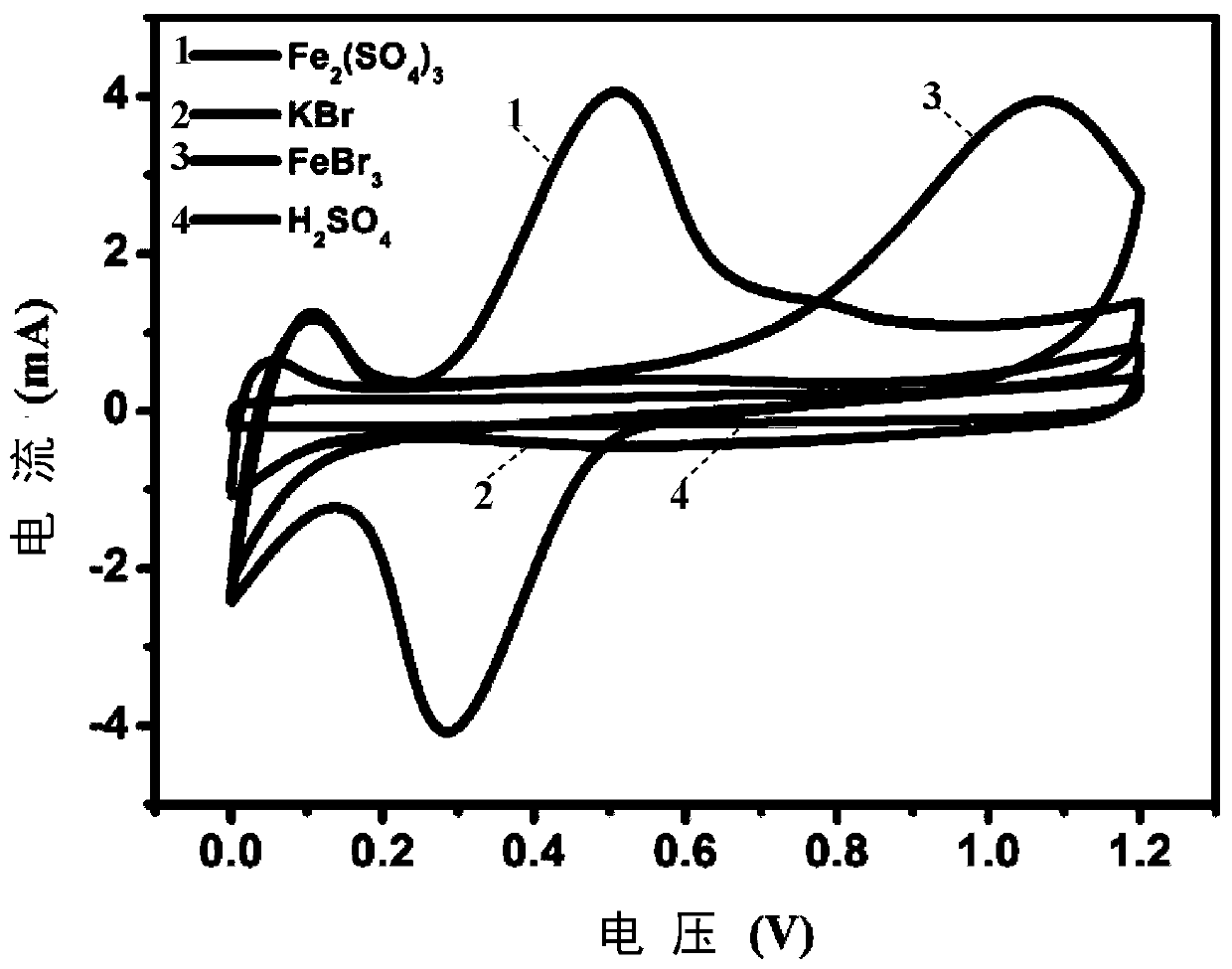

[0025] Preparation of electrolyte: Dissolve 3g of concentrated sulfuric acid with a mass fraction of 98% in 30ml of water, and then add FeBr with different concentrations (0.005M, 0.01M, 0.02M, 0.03M, 0.05M, 0.1M, 0.2M) 3 After that, fully stir to prepare the electrolyte solution.

[0026] The preparation of supercapacitor: be that the polyvinylidene fluoride (PVDF) of 10% by mass percentage is dissolved in the N-2 methylpyrrolidone (NMP) earlier, stir until polyvinylidene fluoride dissolves completely, then the mass percentage is 80% Activated carbon YP-50 and conductive acetylene black with a mass percentage of 10% were poured into the slurry and stirred. After 12 hours of high-speed stirring, the active material was completely dissolved, and the slurry was in the form of a black colloid. Take 20 μL of the above slurry and evenly coat it on the On the current collector, place the coated electrode flatly in a drying oven, bake at 120°C for 5 minutes to volatilize all the N-2 ...

Embodiment 2

[0035] Electrolyte: Dissolve 4.26g of sodium sulfate in 30ml of water to get 1M Na 2 SO 4 solution, and then add different concentrations (respectively 0.005M, 0.01M, 0.02M, 0.03M, 0.05M, 0.1M) of FeBr 3 After that, fully stir to prepare the electrolyte solution. The preparation of the supercapacitor is the same as in Example 1. The electrical performance test is the same as in Example 1.

Embodiment 3

[0037] Electrolyte: Dissolve 5.22g of potassium sulfate in 30ml of water to obtain 1M K 2 SO 4 solution, and then add different concentrations (respectively 0.005M, 0.01M, 0.02M, 0.03M, 0.05M, 0.1M) of FeBr 3 After that, fully stir to prepare the electrolyte solution. The preparation of the supercapacitor is the same as in Example 1. The electrical performance test is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com