Multi-parameter adjustable operating mechanism based on dual-coil structure

A dual-coil structure and operating mechanism technology, applied in the direction of electromagnetic relay details, relays, electrical components, etc., can solve the problems of incomplete design and analysis theory of high-voltage DC relay products, backward test evaluation technology, etc., and achieve the movement process of the armature. Flexible and controllable, the effect of great reference value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

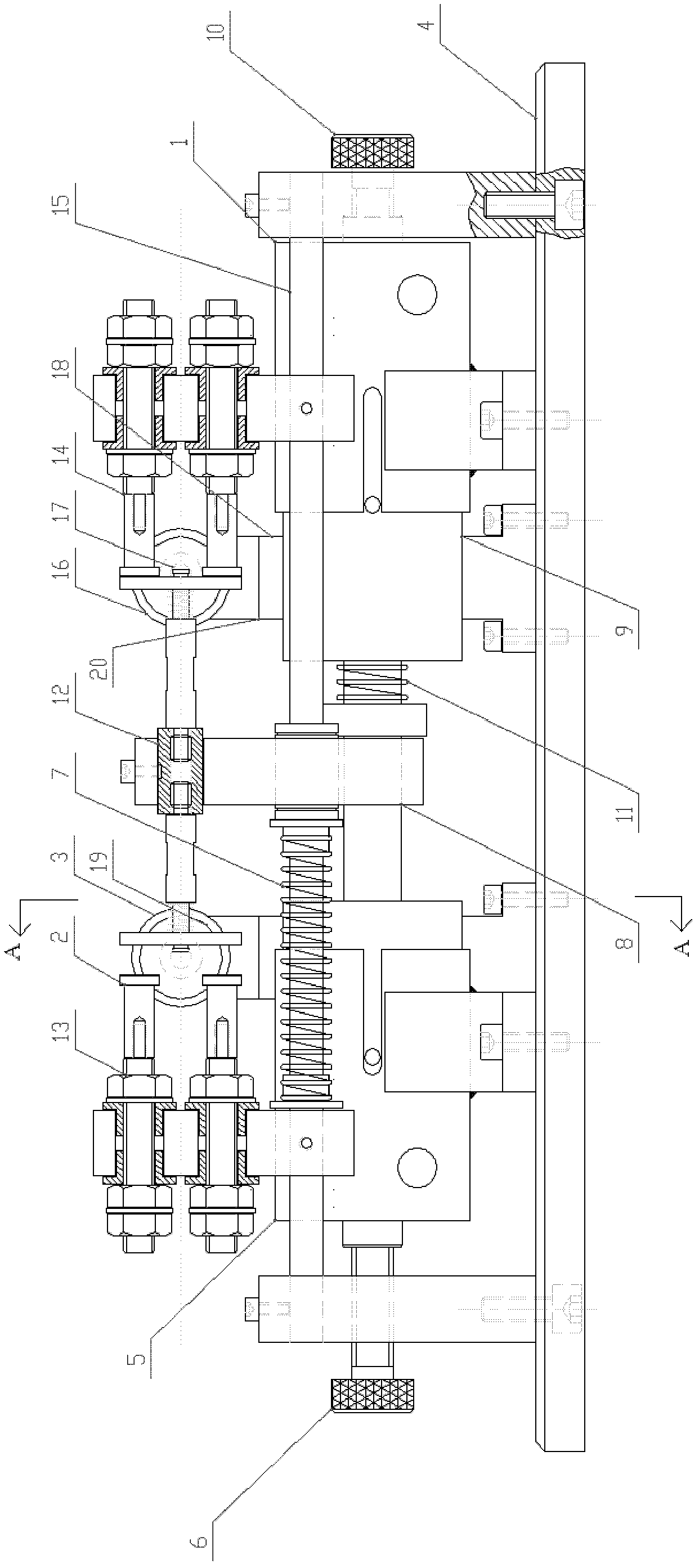

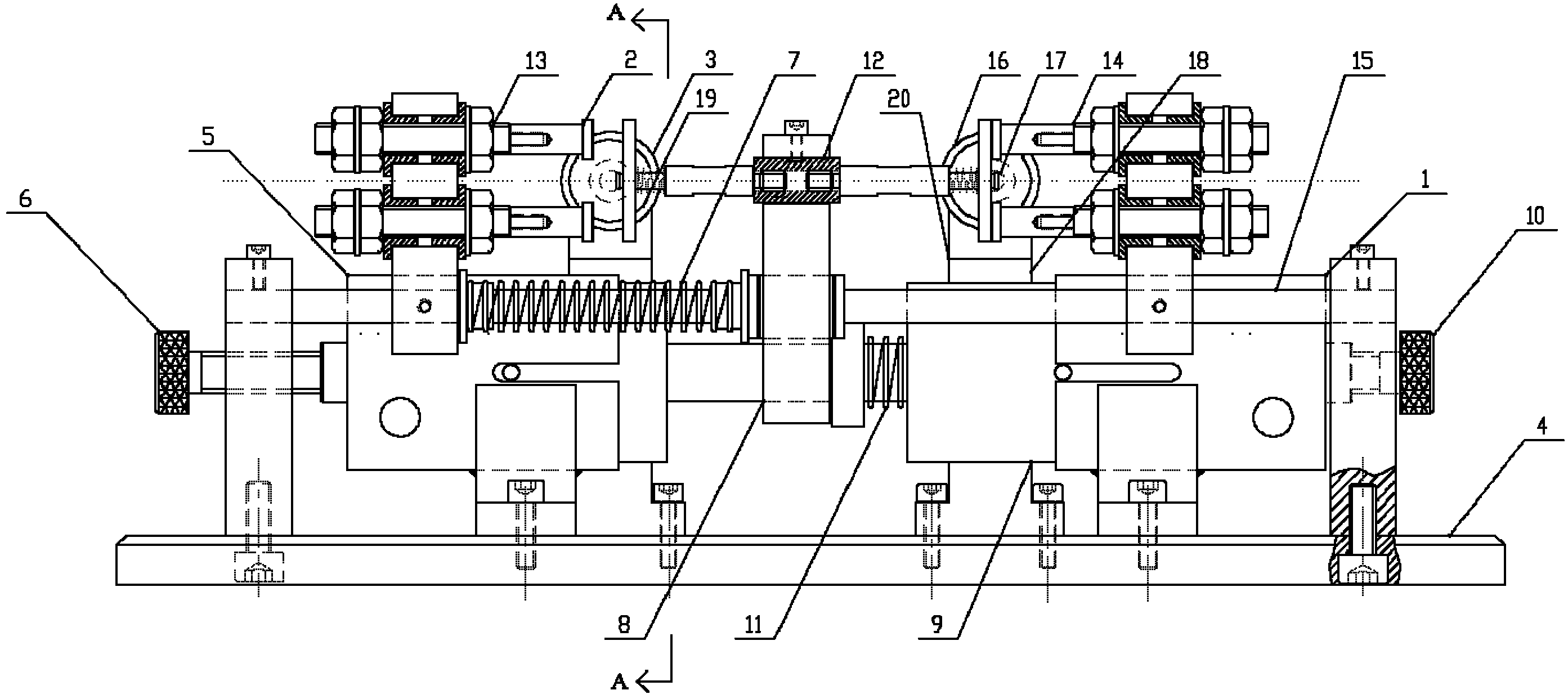

[0010] Specific implementation mode 1. Combination figure 1 Describe this embodiment, a multi-parameter adjustable operating mechanism based on a double coil structure, which includes an electromagnetic system 1, a contact system 2, a magnetic blowout system 3 and a base 4,

[0011] The magnetic blowing arc extinguishing system 3 is installed on both sides of the contact system 2, the electromagnetic system 1 and the magnetic blowing arc extinguishing system 3 are fixed on the base 4 by screws, and the contact system 2 is provided with a contact clamping mechanism for clamping For the moving contact and the static contact, the electromagnetic system 1 is used as the power source to drive the contact system 2 to realize the breaking and closing operations of the moving contact and the static contact.

specific Embodiment approach 2

[0012] Specific embodiment two, combine figure 1 Describe this embodiment, this embodiment is to further limit the electromagnetic system 1 in the specific embodiment one: the electromagnetic system 1 includes a suction coil 5, a suction coil stroke adjustment mechanism 6, a suction buffer spring 7, an armature 8, and a reaction coil 9. Reaction force coil stroke adjustment mechanism 10 and reaction force buffer spring 11,

[0013] The suction coil stroke adjustment mechanism 6 and the reaction coil stroke adjustment mechanism 10 are both spiral telescopic adjustment mechanisms, which are respectively fixed on the column, and the column is fixed on the base 4, and the suction coil 5 is connected to the adjustable end of the suction coil stroke adjustment mechanism 6 through a nut. Fixedly connected, the suction coil stroke adjustment mechanism 6 is used to adjust the movement of the suction coil 5 in the horizontal direction, and the reaction force coil 9 is fixedly connected ...

specific Embodiment approach 3

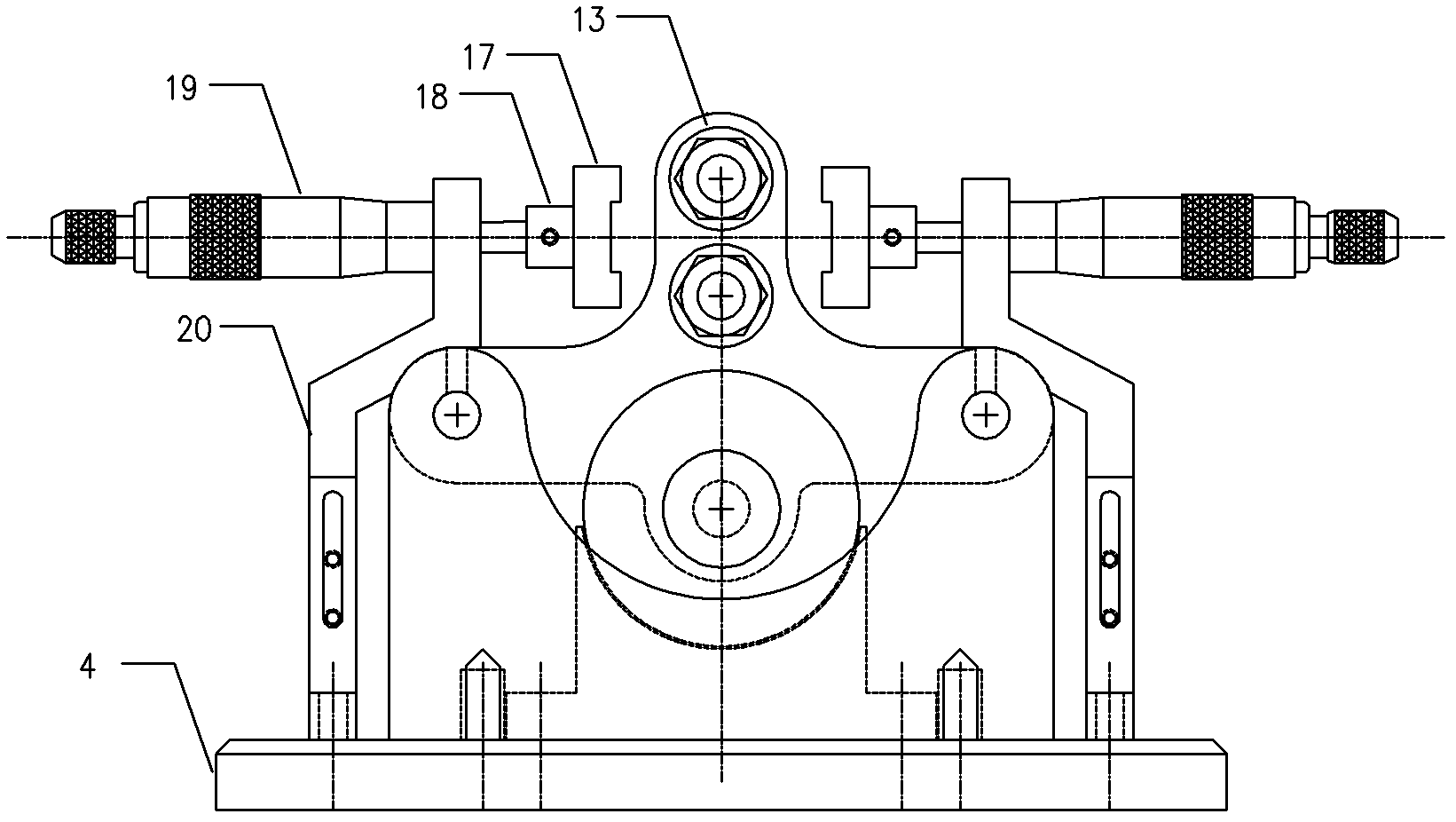

[0016] Specific implementation mode three, combination figure 1 Describe this embodiment, this embodiment is a further limitation of the second specific embodiment: the magnetic blowout arc extinguishing system 3 includes a moving contact clamping mechanism 12, a normally open static contact clamping mechanism 13, a normally closed static contact Card loading mechanism 14 and guide rail 15,

[0017] The guide rail 15 is a screw connecting rod, one end of the guide rail 15 is fixed on the column of the fixed suction coil stroke adjustment mechanism 6, the other end of the guide rail 15 is fixed on the column of the fixed reaction force coil stroke adjustment mechanism 10, and the moving contact clamping mechanism 12 is installed on the guide rail 15, the moving contact clamping mechanism 12 is fixedly connected with the armature 8, and the armature 8 can drive the moving contact clamping mechanism 12 to move along the guide rail 15, when the electromagnetic system 1 is engaged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com