Water cooling structure of axial magnetic flux permanent-magnet wind driven generator

A wind turbine and axial flux technology, applied in the direction of magnetic circuit shape/style/structure, winding conductor shape/style/structure, magnetic circuit static parts, etc., can solve the problem of reduced motor efficiency and increased bearing load , motor temperature rise and other issues, to avoid local hot spots, meet the cooling requirements, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

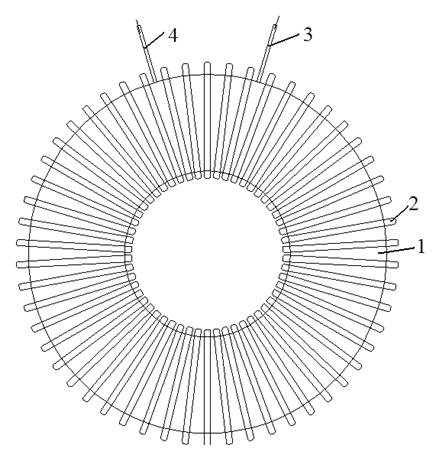

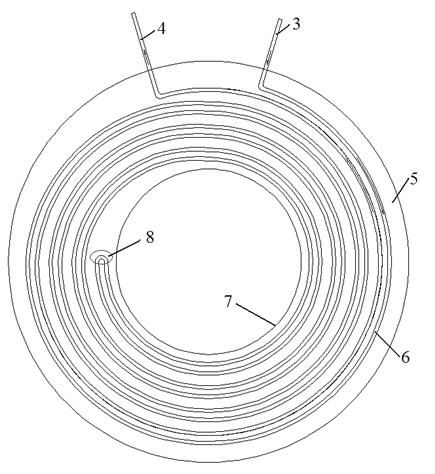

[0018] Such as figure 1 , figure 2 As shown, the present invention includes a stator core 1 and a stator winding 2 wound on the stator core 1, a cooling interlayer 5 is arranged in the disk body of the stator core 1 of a permanent magnet wind power generator, and a water inlet 3 is provided on the top of the cooling interlayer 5 and outlet 4. The cooling channel 6 is arranged inside the cooling interlayer 5, the cooling channel 6 has a double helix structure in the radial direction, and is connected with a section of elbow 8 near the rotating shaft 7 of the disc to ensure that the water flow can return along the cooling channel 6 To the water outlet 4 of the cooling structure. In the present invention, the cooling channel 6 can be made of a copper tube or processed in the cooling interlayer 5 such as figure 2 Groove configuration shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com