PTC (positive temperature coefficient) electrical heating assembly

A technology of electric heating and components, applied in the direction of ohmic resistance heating parts, heating element materials, etc., can solve the problems of poor safety and easy fire, and achieve the effect of improving safety, reducing the possibility of fire, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

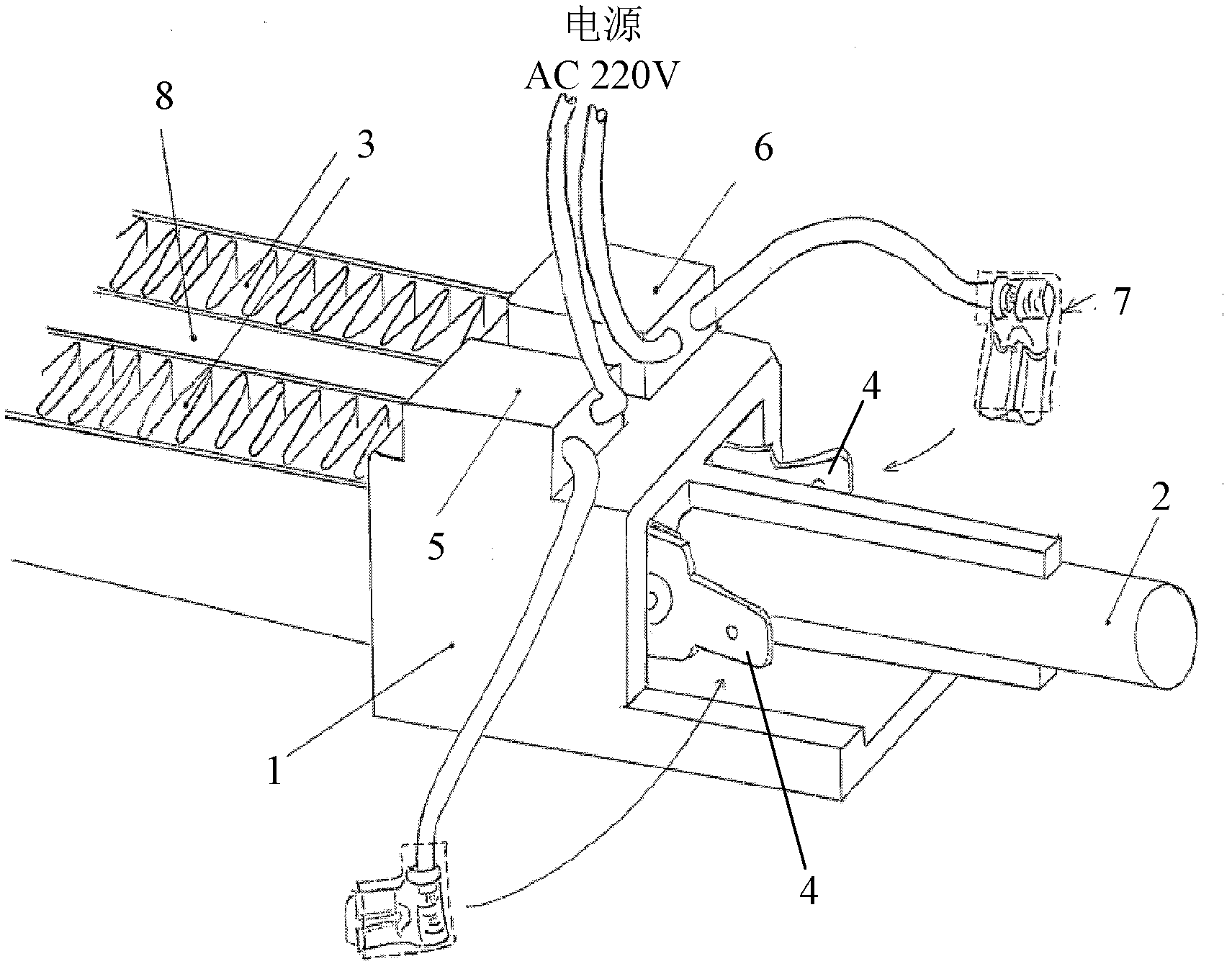

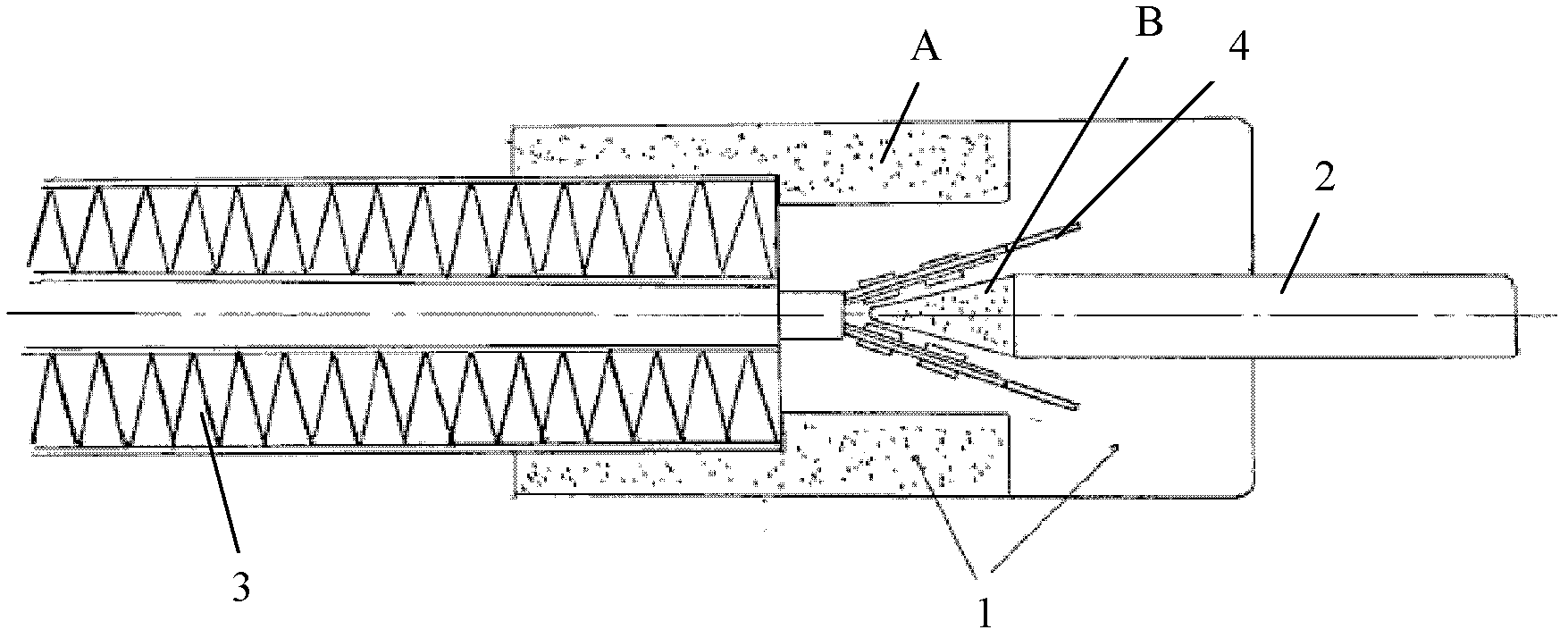

[0028] According to an embodiment of the present invention, a PTC electric heating assembly is provided, such as figure 2 and image 3 As shown, the PTC electric heating assembly according to the embodiment of the present invention includes a PTC base 1, a mounting protrusion 2, a heat sink 3, and two conductive blade terminals 4, wherein the PTC base 1 is socketed to the heat sink 3, Two conductive blade terminals 4 are connected to the heat sink 3, the installation protrusion 2 is fixed in the PTC base 1 (may be integrally formed with the base 1), and the installation protrusion 2 is inserted between the two conductive blade terminals 4 .

[0029] Such as image 3 As shown, the surface of the part B where the installation protrusion 2 is inserted between the two conductive blade terminals 4 is also coated with silicone, and the part B where the installation protrusion 2 is inserted between the two conductive blade terminals 4 is tapered. In addition, the part A where the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com