Method for controlling a melt process in an arc furnace and signal processing component, program code, and data medium for performing said method

A signal processing device, electric arc furnace technology, applied in furnace control devices, electric heating devices, electric furnaces, etc., can solve problems such as difficult and strong interventions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

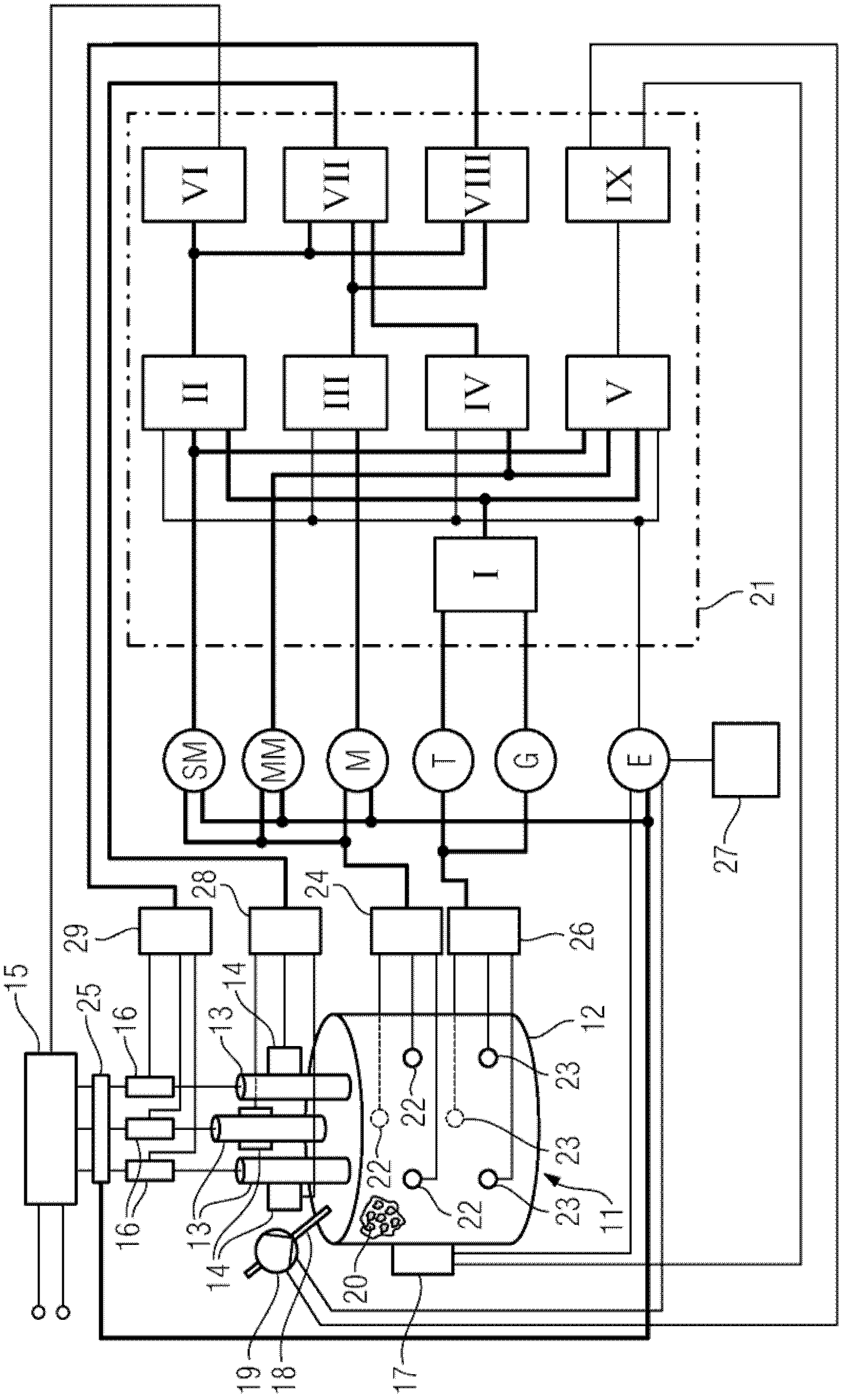

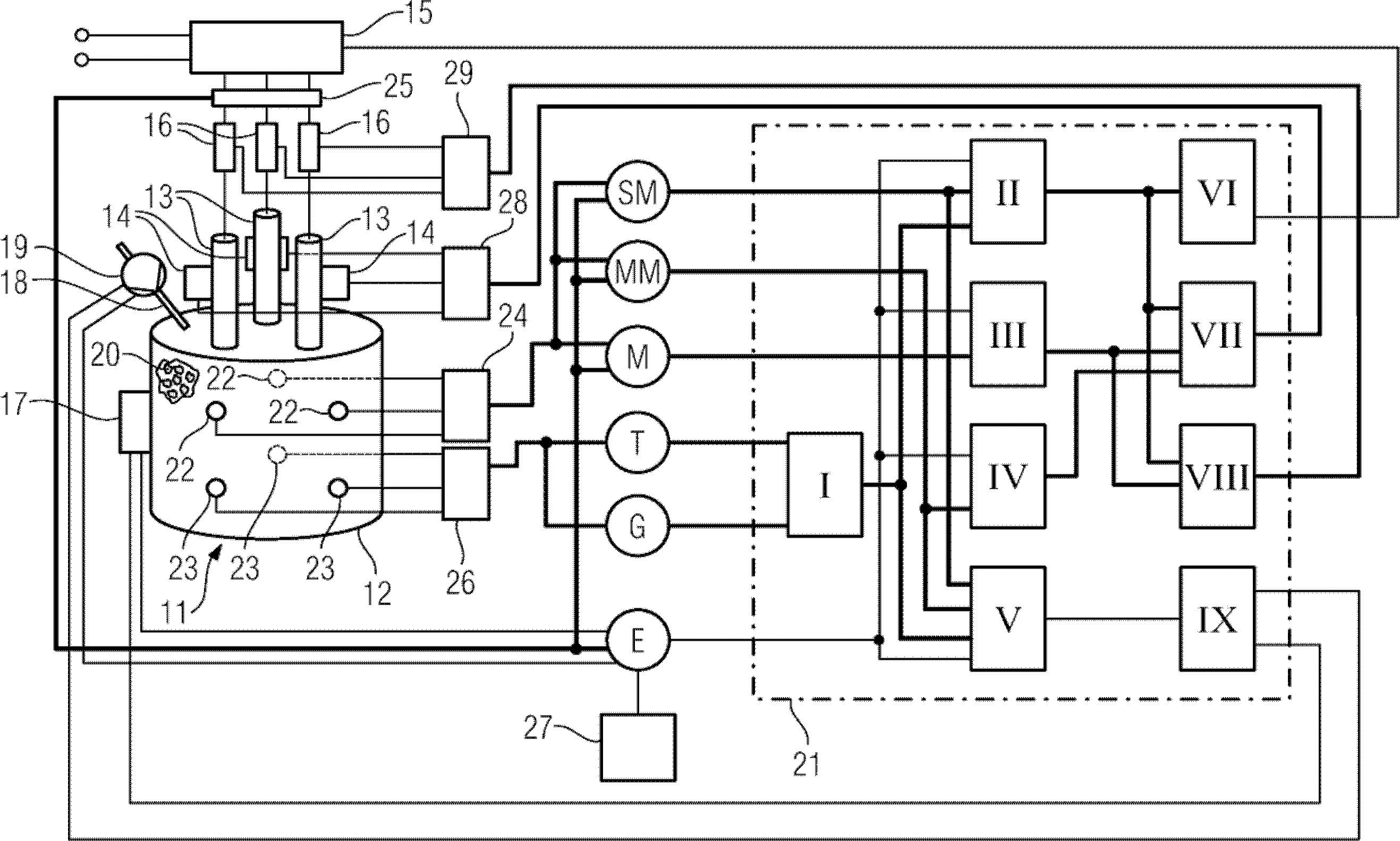

[0026] The electric arc furnace 11 has a furnace vessel 12 which is filled, not shown, with melt (scrap). Preferably, three electrodes 13 protrude into the furnace vessel, which electrodes can be raised or lowered horizontally along their longitudinal axes by means of actuators 14 (hydraulic motors or servo motors). The electrodes 13 are supplied with three-phase electricity via a furnace transformer 15 , wherein each electrode 13 can moreover be associated with an additional reactor 16 so that said additional reactor 16 can generate lost electrical power in a targeted manner. Furthermore, a burner 17 is schematically illustrated, with which chemical energy can be introduced into the furnace vessel 12 by burning fuel. A lance 18 also protrudes into the furnace vessel 12 , wherein gas can be blown into the furnace vessel and thus into the furnace charge by means of a pump 19 .

[0027] To melt the melt 20 in the form of metal scrap in the electric arc furnace 11 , an electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com