Welding method for steel structure in environment of -15 DEG C to 35 DEG C

A welding method and steel structure technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as waste of construction period, achieve the effect of ensuring work efficiency and quality, solving technical problems, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In the present invention, welders participating in welding construction at low temperatures, especially -15°C to -35°C, or referred to as negative temperature environments, should be trained in negative temperature welding techniques and pass the examination before they can participate in negative temperature welding construction.

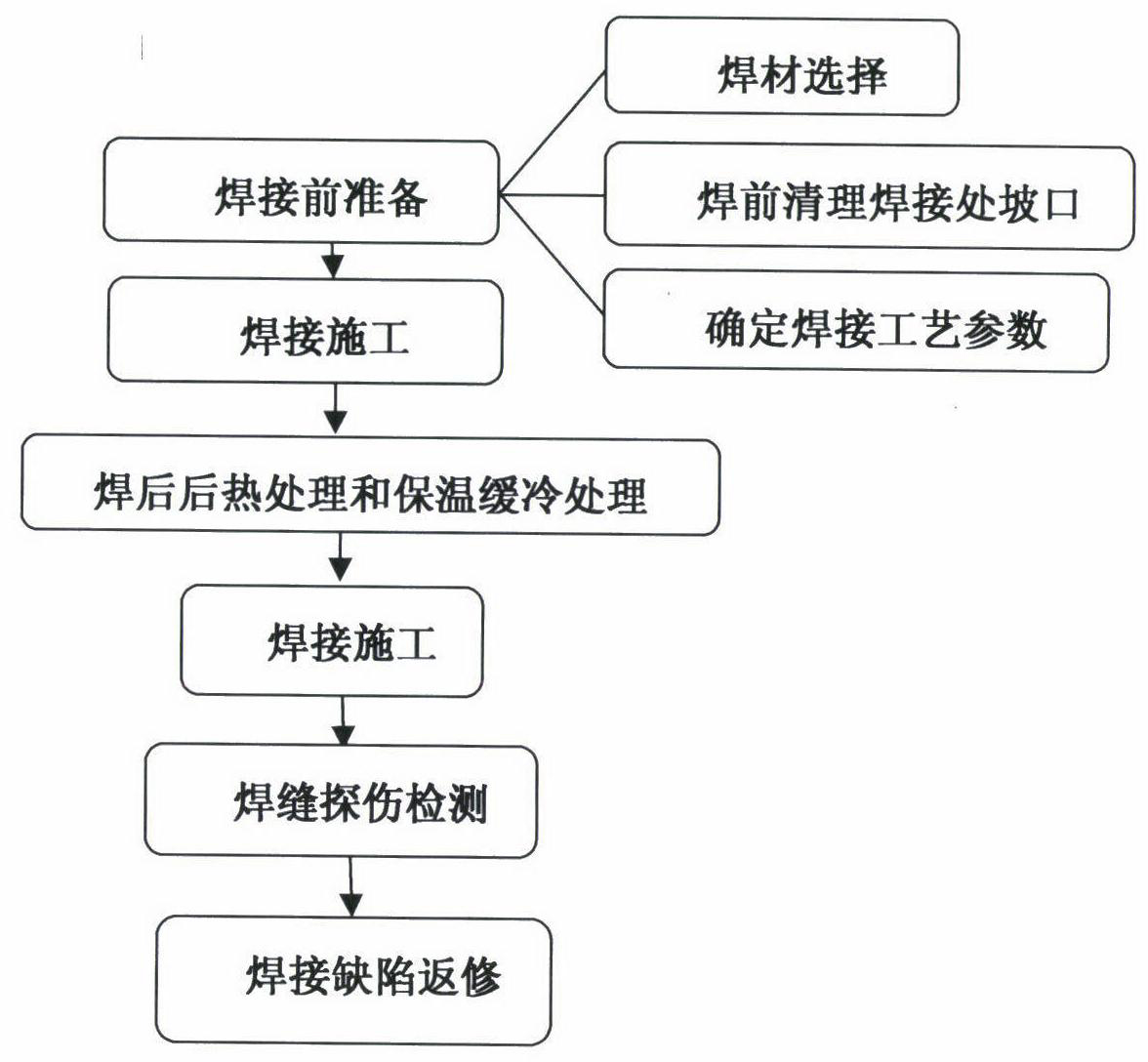

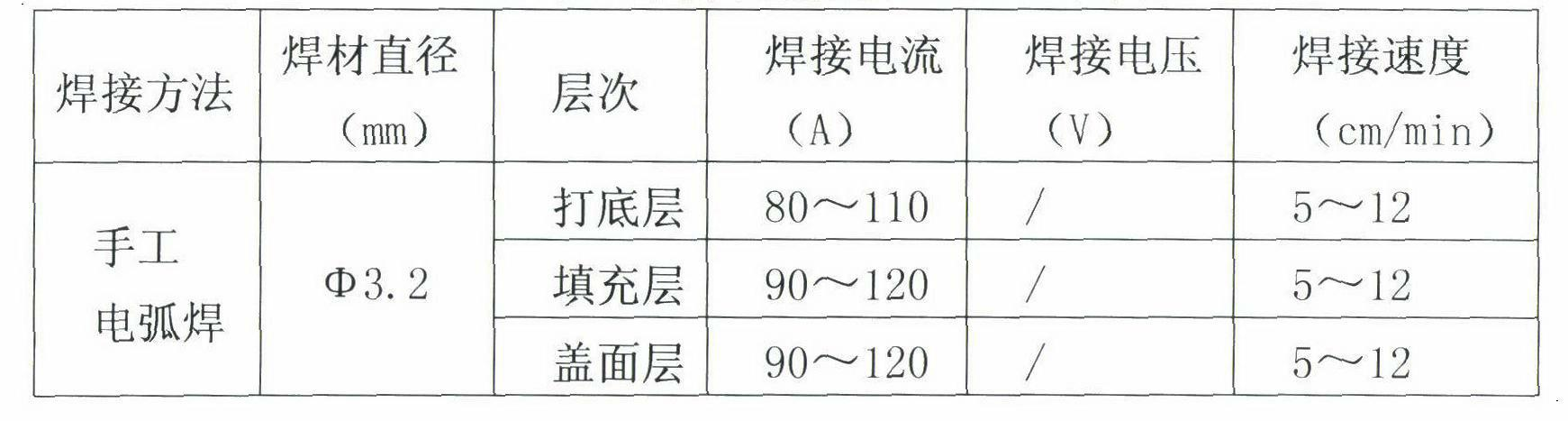

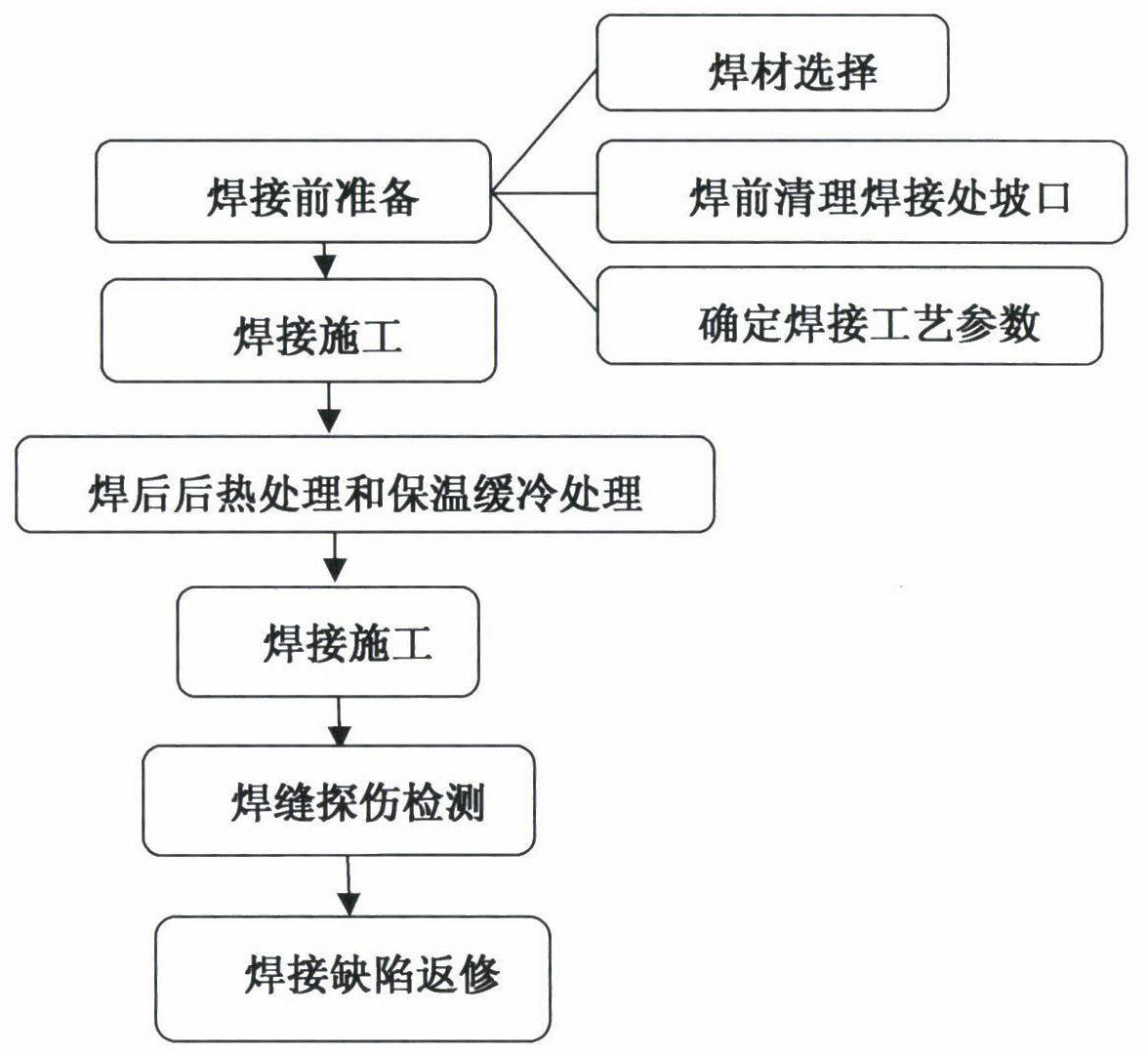

[0012] Welding construction procedures include: pre-welding preparation, welding construction, post-weld heat treatment, weld inspection and welding defect treatment; among them, pre-welding preparation includes welding material selection, pre-weld cleaning and preheating, and determination of welding process parameters; immediately after welding Carry out post-welding heat treatment, the post-heating temperature is 180-230°C, and not less than 1h; take emergency measures immediately after welding in case of power failure, use cotton insulation to cover the weld surface for insulation and slow cooling, and the insulation rock wool wrapped is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com