Mechanical arm

A technology of mechanical arm and machine body, applied in the field of mechanical arm, can solve the problems of large volume, inability to adapt to teaching demonstration, small volume and portability, etc., and achieve the effect of high operation accuracy, high degree of automation, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

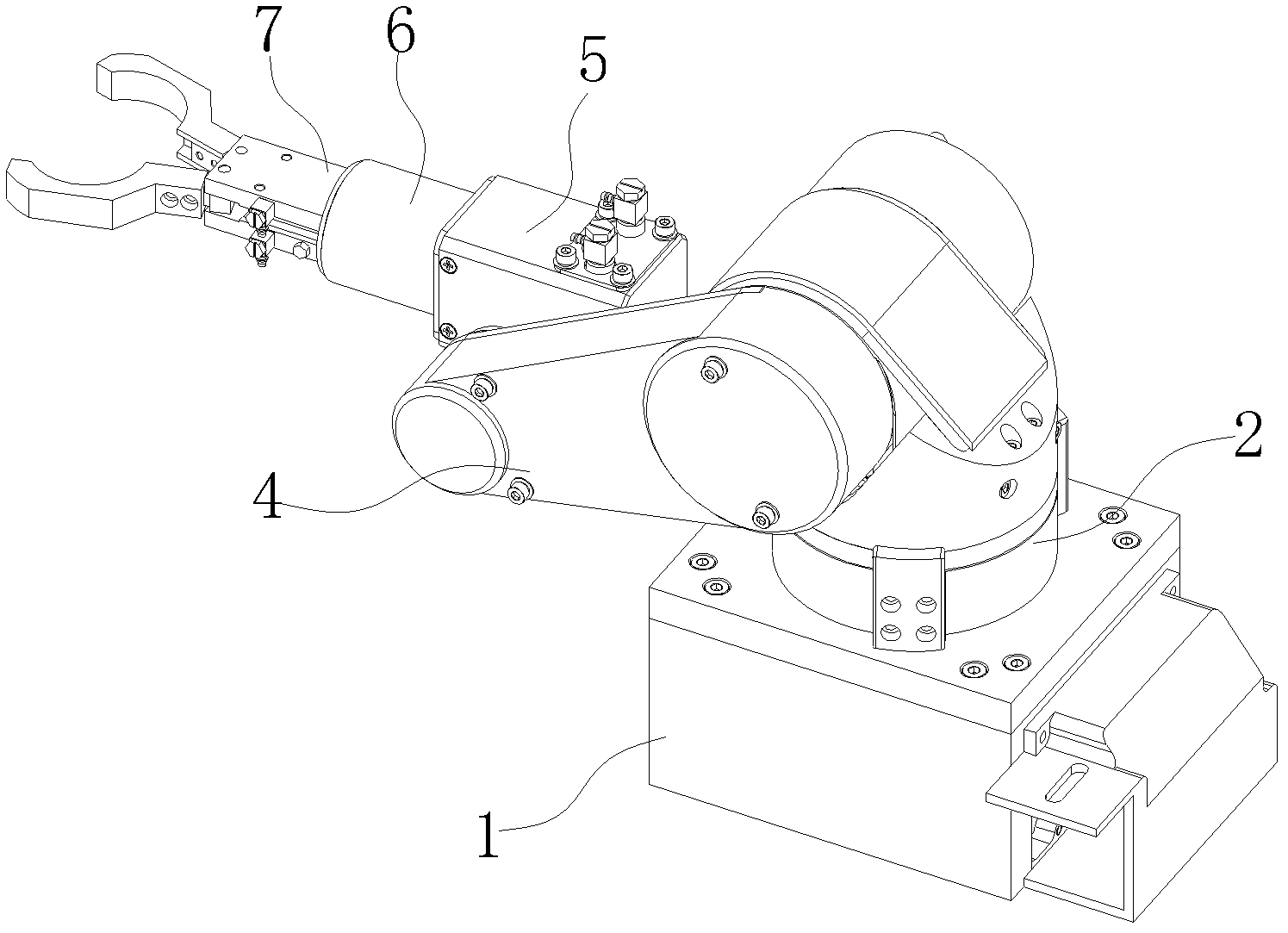

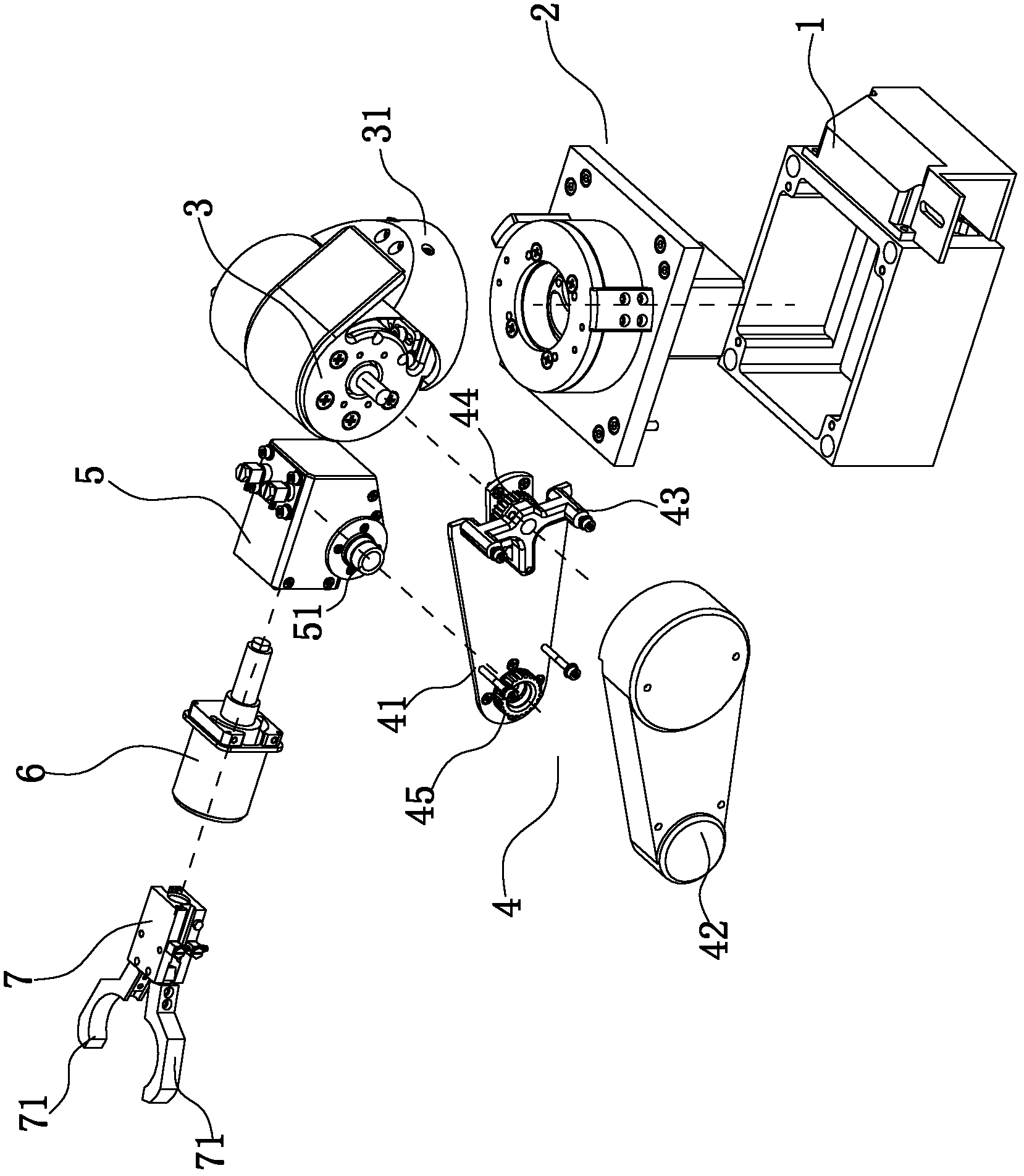

[0030] Such as figure 1 , 2 As shown, it is a mechanical arm of the present invention, which includes a base 1, a swing cylinder 3, a swing arm assembly 4, a motor 6 and a cylinder 7, and the cylinder part of the swing cylinder 3 is rotatably connected to the top of the base 1, and the swing arm One end of the assembly 4 is synchronously connected to the free end of the swing cylinder 3, the body part of the motor 6 is rotatably connected to the other end of the swing arm assembly 4, and the cylinder part of the cylinder 7 is connected to the rotating shaft of the motor 6, and the Two opposite grippers 71 are installed at the free end, and when the free end of the cylinder 7 stretches, the opening and closing of the two grippers 71 can be realized.

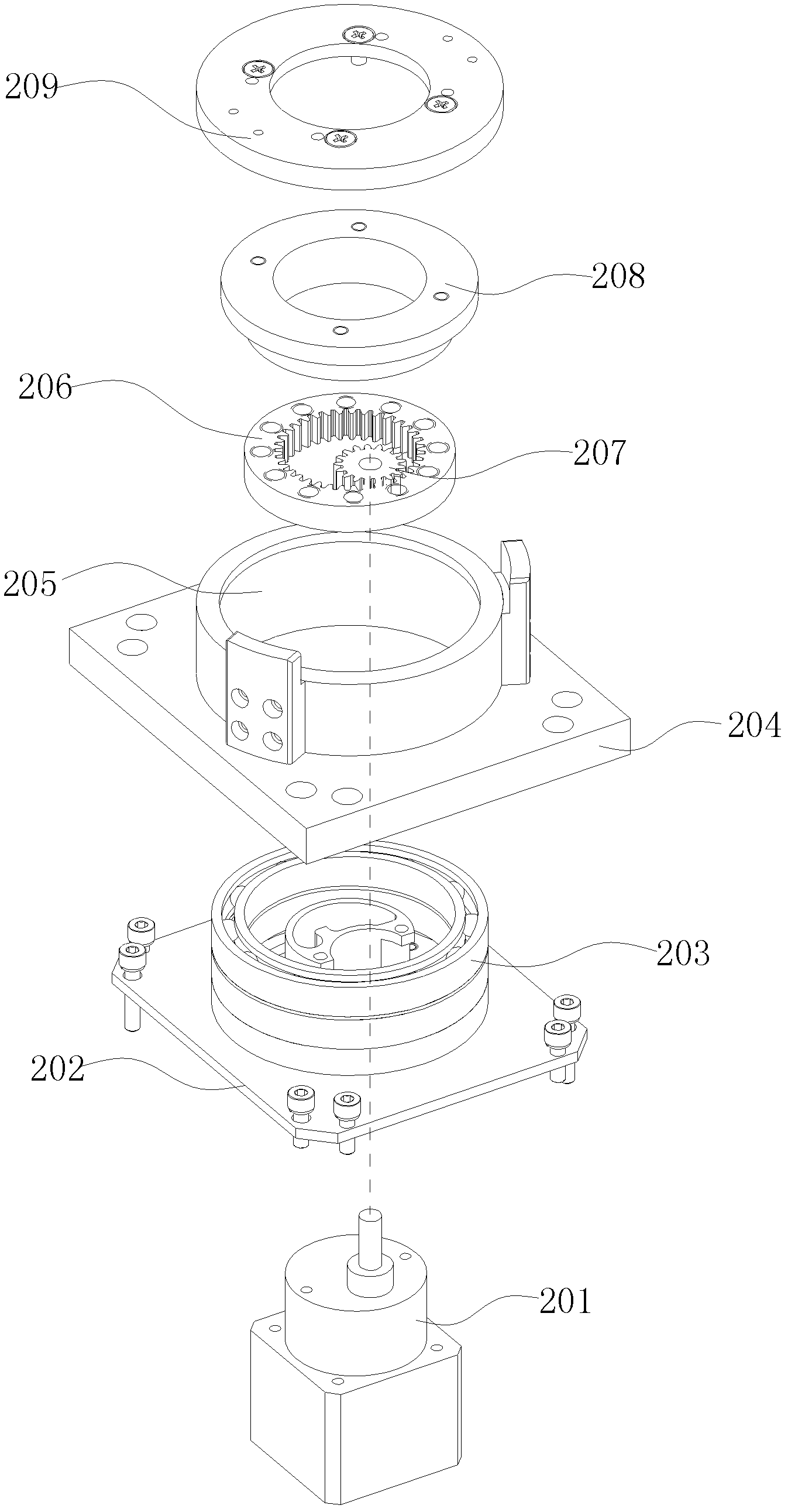

[0031] The swing arm assembly 4 includes an inner side plate 41 and an outer baffle plate 42, and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap