Liquid crystal glass packaging box

A technology of liquid crystal glass and packaging boxes, applied in the field of packaging, can solve problems such as scrapping, glass plate grinding, and glass plate damage, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

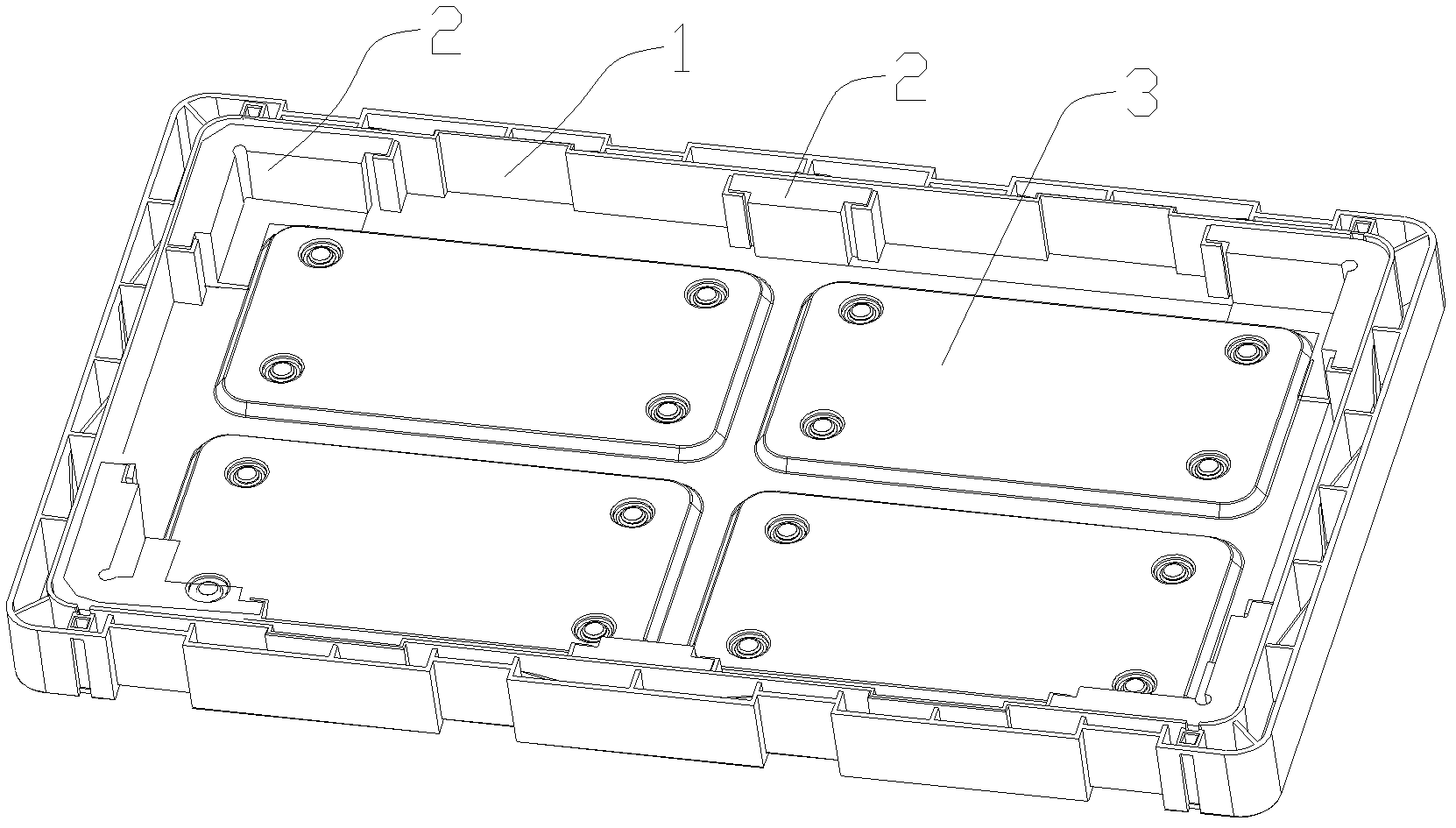

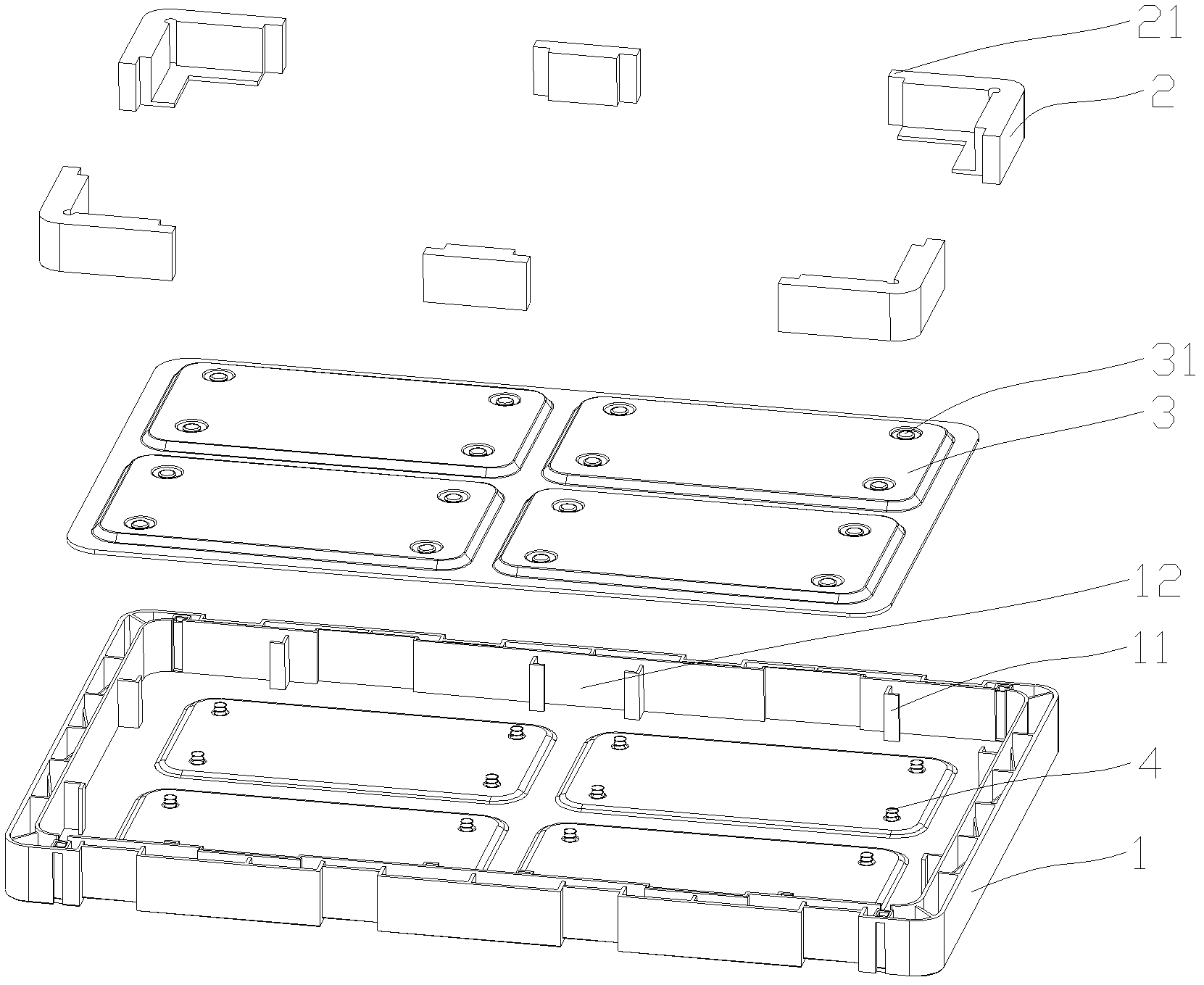

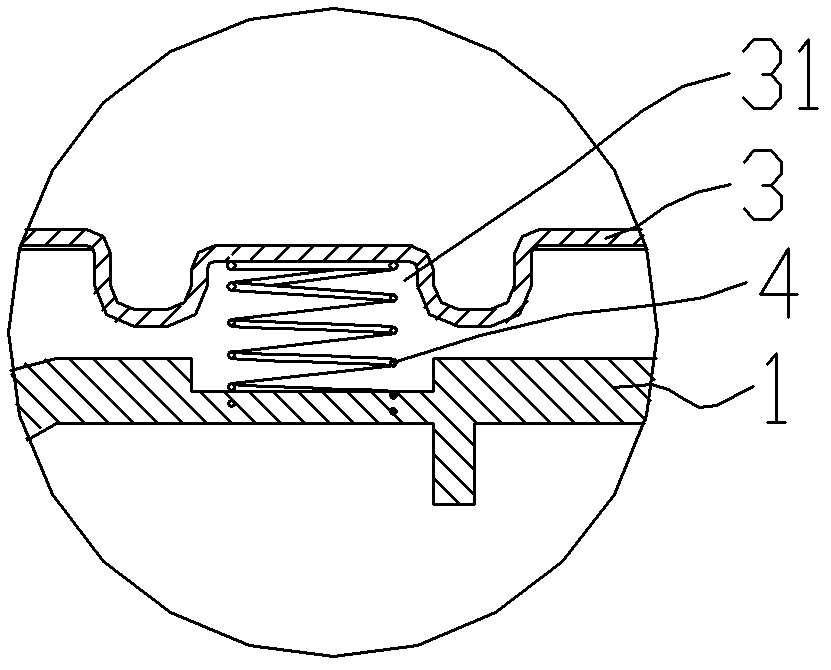

[0020] The invention discloses a liquid crystal glass packaging box, which includes a box body 1, and a buffer block 2 with a material different from that of the box body 1 is arranged inside the box body 1.

[0021] The liquid crystal glass packaging box of the present invention adopts a split structure, the box body 1 and the buffer block 2 are made of different materials respectively, the buffer performance of the buffer block 2 is better than that of the box body 1, and the buffer block 2 is made of a material with good buffer performance For example, EPP (expanded polypropylene), EPE (expanded polyethylene), EPS (expanded polystyrene), etc., and the box body 1 is mainly used to fix the buffer block 2 and ensure the strength of the entire packaging box, so the box The body 1 can be injection-molded with ordinary plastic materials, such as ABS (acrylonitrile-butadiene-styrene plastic), HDPE (high-density polyethylene), etc., because the box body 1 does not need to use a cush...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap