Oil and air hybrid driven lifting control device

A technology of lifting control and oil and gas mixing, applied in lifting devices, fine working devices, lifting frames, etc., can solve the problems of continuous noise, rising oil temperature, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

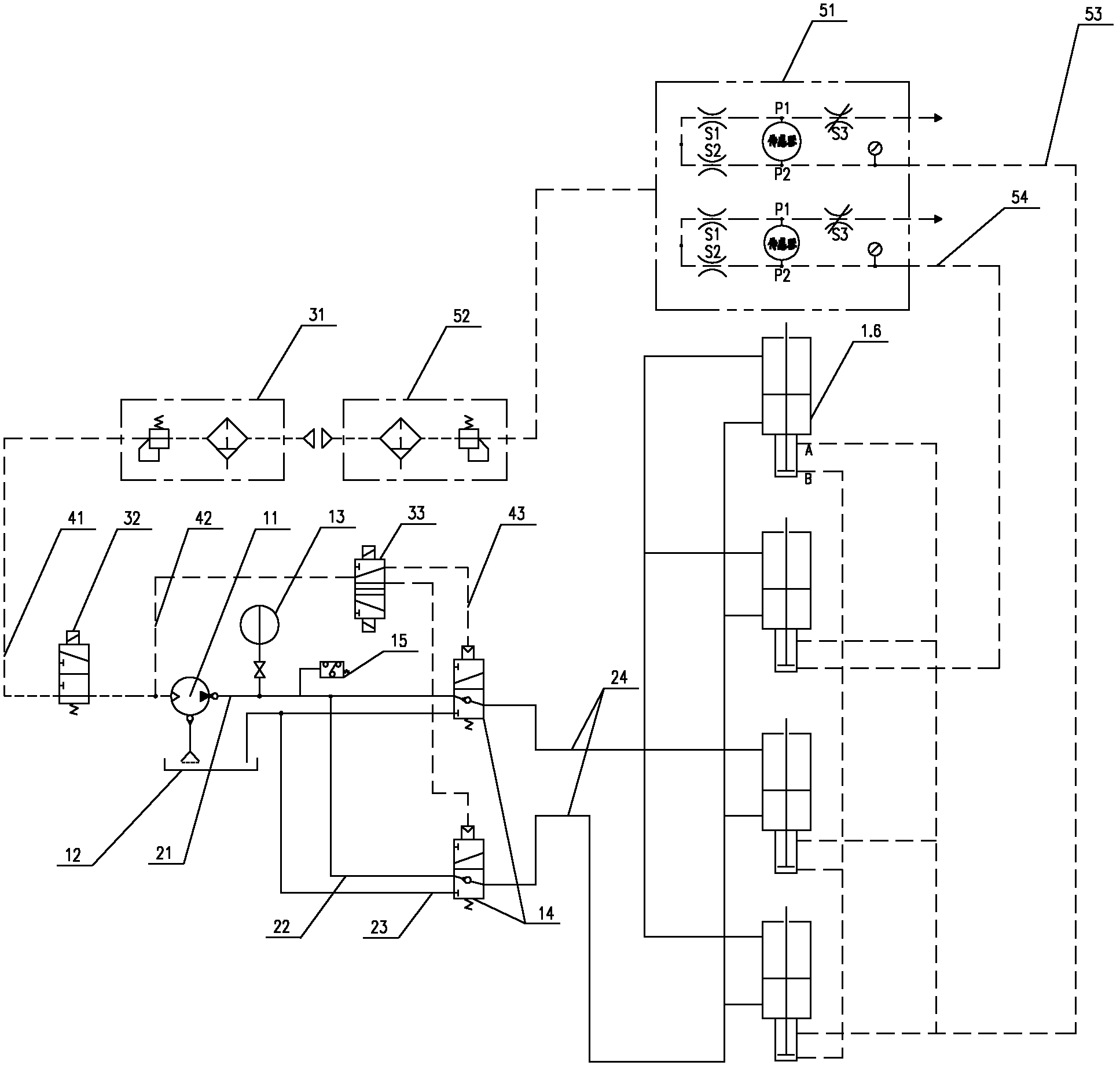

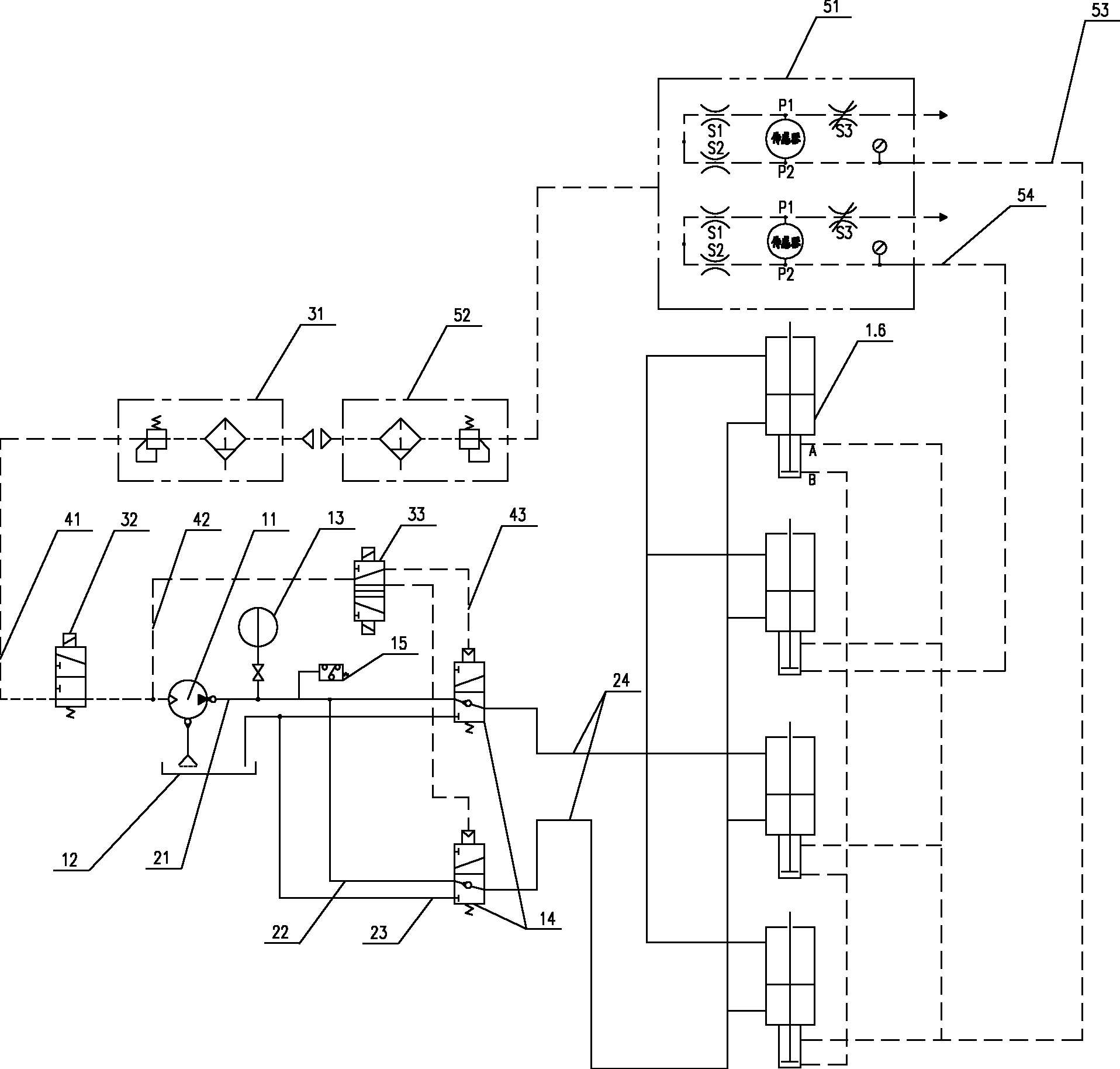

[0026] A lifting control device driven by a mixture of oil and gas, referring to figure 1 As shown, it is mainly composed of compressed air components, pneumatic position sensor components, and hydraulic components. The solid line represents the hydraulic oil circuit, and the dotted line represents the air circuit. The compressed air assembly includes a first filter decompression valve 31, a first electromagnetic reversing valve 32 and a second electromagnetic reversing valve 33; the hydraulic assembly includes a pneumatic hydraulic pump 11, an oil tank 12, a pneumatic reversing valve 14 and a lift Oil cylinder 16 ; the pneumatic position sensor assembly includes a pneumatic position sensor 51 and a second filter decompression valve 52 .

[0027] This lifting oil cylinder 16 is four horizontal bars double-acting oil cylinders. Oil tank 12 li has been filled with anti-wear pressure oil.

[0028] as attached figure 1 As shown, the hydraulic assembly includes a pneumatic hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com