Method for detecting cleanliness of cathode electrophoretic coating production equipment

A cathodic electrophoretic coating, cleaning technology, applied in the direction of electrolytic coating, electrophoretic plating, coating, etc., can solve the problems of pollution and waste, and achieve the effects of sensitive detection, reliable detection results and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

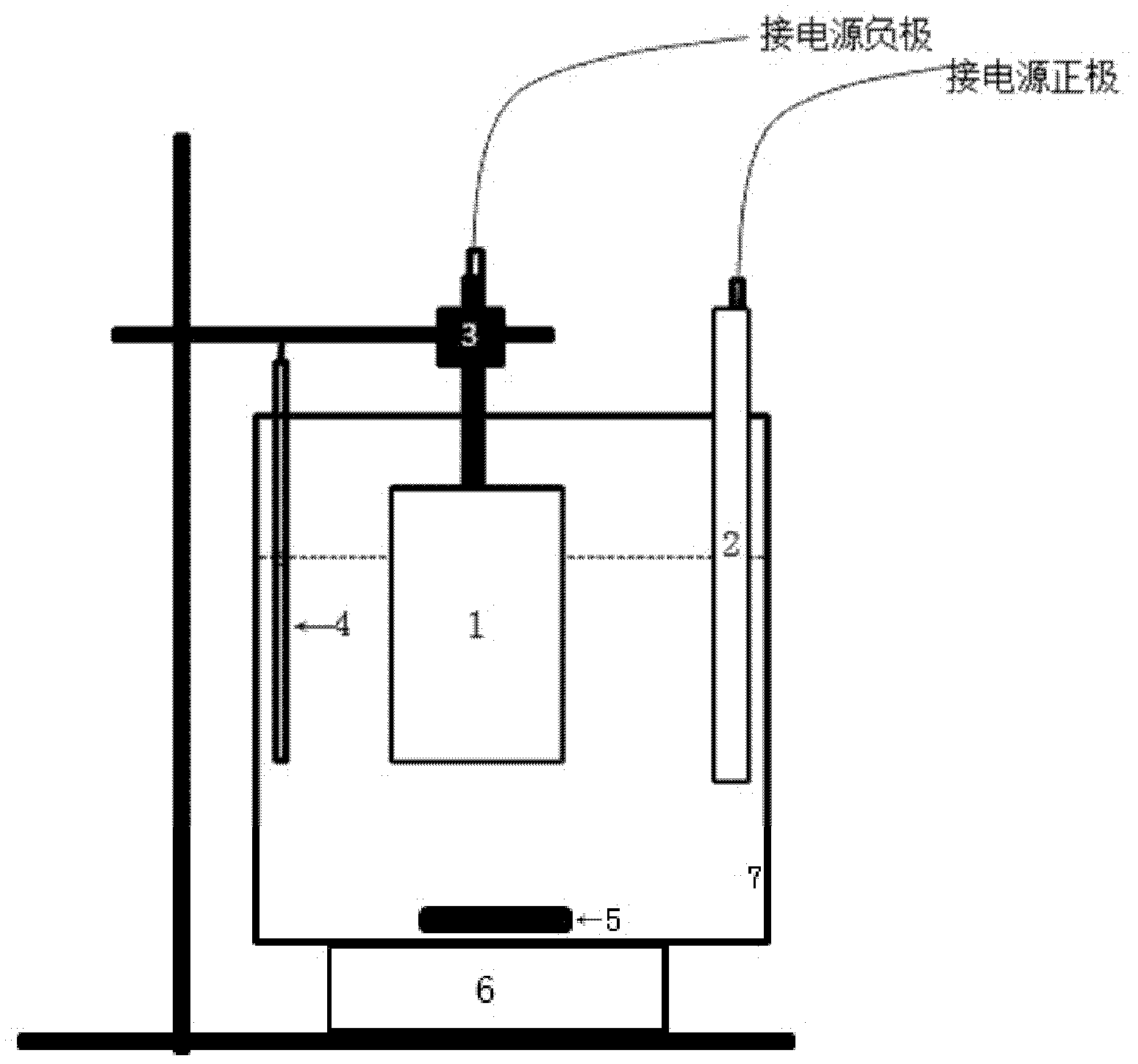

[0032] A method for detecting whether the cathodic electrophoretic coating production equipment is cleaned (dipping method), comprising the following steps:

[0033] (1) Cleaning equipment: clean the newly installed reactor (R-401), material pipelines (including valves), and clean the water samples for step (5) after standing for 20 minutes;

[0034] (2) Prepare bath solution: get the bath solution after mixing and stirring the ingredients in the following parts by weight:

[0035] Pure water: 40 parts

[0036] PN 150 F-2 (available from Guangzhou Nippon Paint Co., Ltd.): 40 copies

[0037] PN 150 F-1 (available from Guangzhou Nippon Paint Co., Ltd.): 20 copies;

[0038] The pure water refers to water with conductivity ≤ 2μs / cm;

[0039] (3) Bath aging: heat the bath at 40°C for 16 hours, and then replenish its volatile part with pure water;

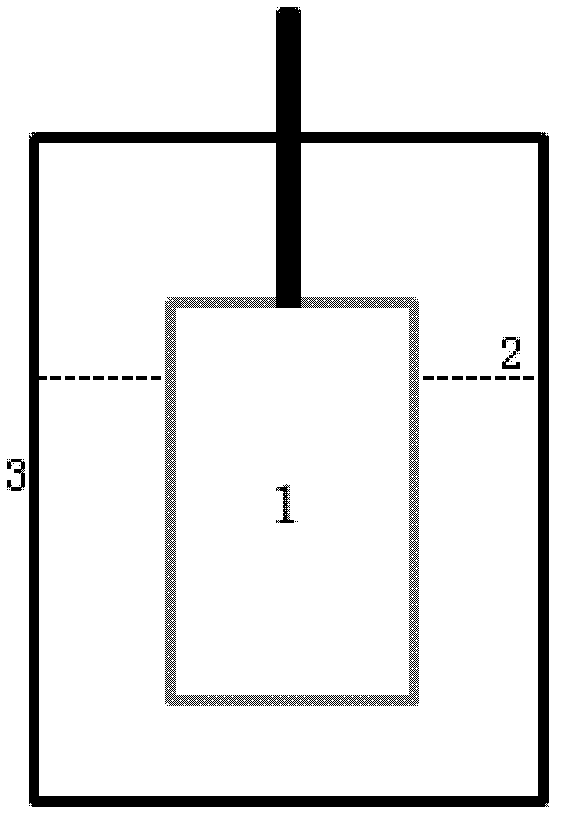

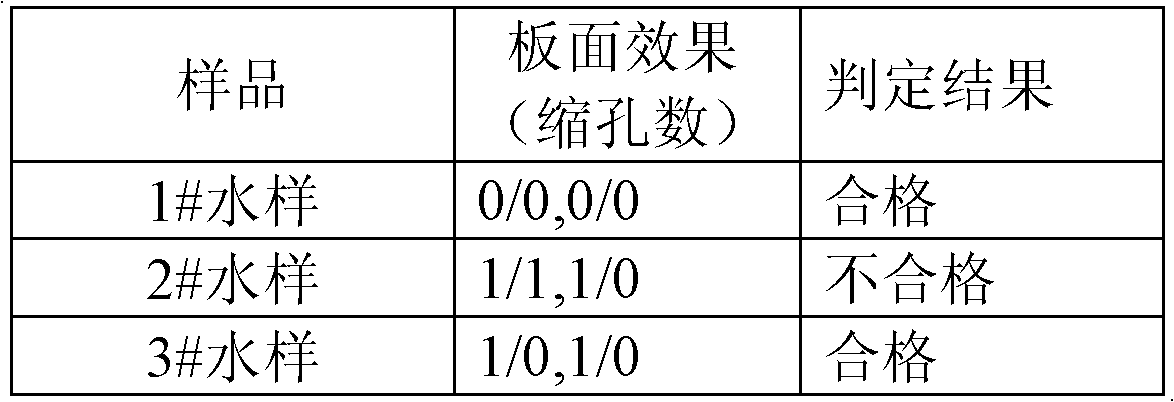

[0040] (4) Electrophoresis: The pre-treated phosphating steel plate (specification: 150mm×70mm) was electrophoresed in the electrop...

Embodiment 2

[0048] A method for detecting whether the cathodic electrophoretic coating production equipment is cleaned (dipping method), comprising the following steps:

[0049] (1) Cleaning equipment: clean the electrophoresis product 210L inner-coated small-mouth packaging barrel, and use the cleaning water sample for step (5) after standing for 20 minutes;

[0050] (2) Prepare bath solution: get the bath solution after mixing and stirring the ingredients in the following mass percentages:

[0051] Pure water: 50 parts

[0052] PN 310 F-2 (available from Guangzhou Nippon Paint Co., Ltd.): 30 copies

[0053] PN 310 F-1 (available from Guangzhou Nippon Paint Co., Ltd.): 15 copies;

[0054] The pure water refers to water with conductivity ≤ 2μs / cm;

[0055] (3) Bath aging: heat the bath at 40°C for 16 hours, and then replenish its volatile part with pure water;

[0056] (4) Electrophoresis: The pre-treated phosphating steel plate (specification: 150mm×70mm) was electrophoresed in the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com