Vertical dryer

A vertical dryer and dryer technology, which is applied in dryers, drying, drying chambers/containers, etc., can solve the problems of easy blockage of filters, high production costs, and large equipment investment, and achieve uniform heat exchange. The effect of sufficient, improved drying effect and high dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

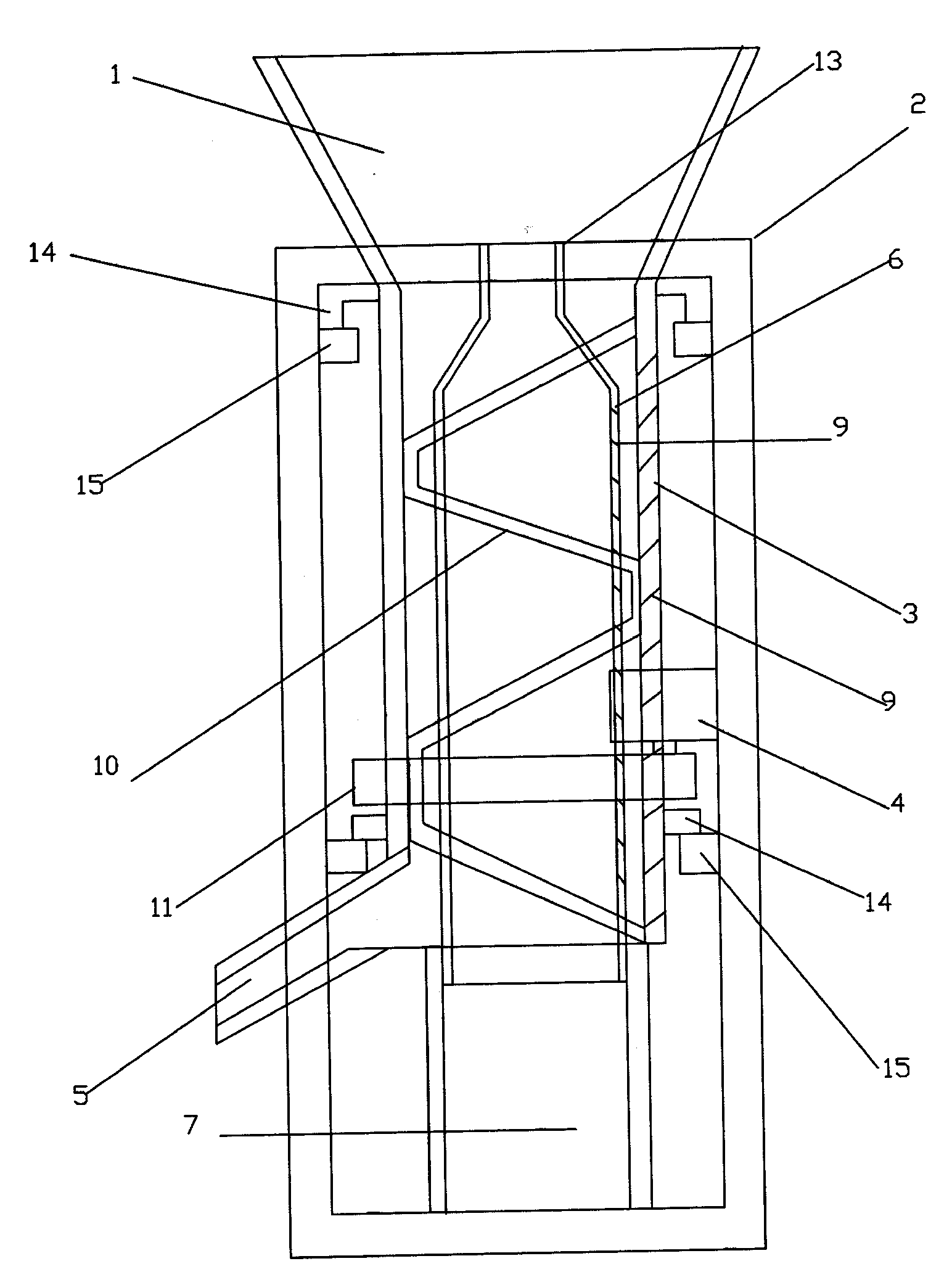

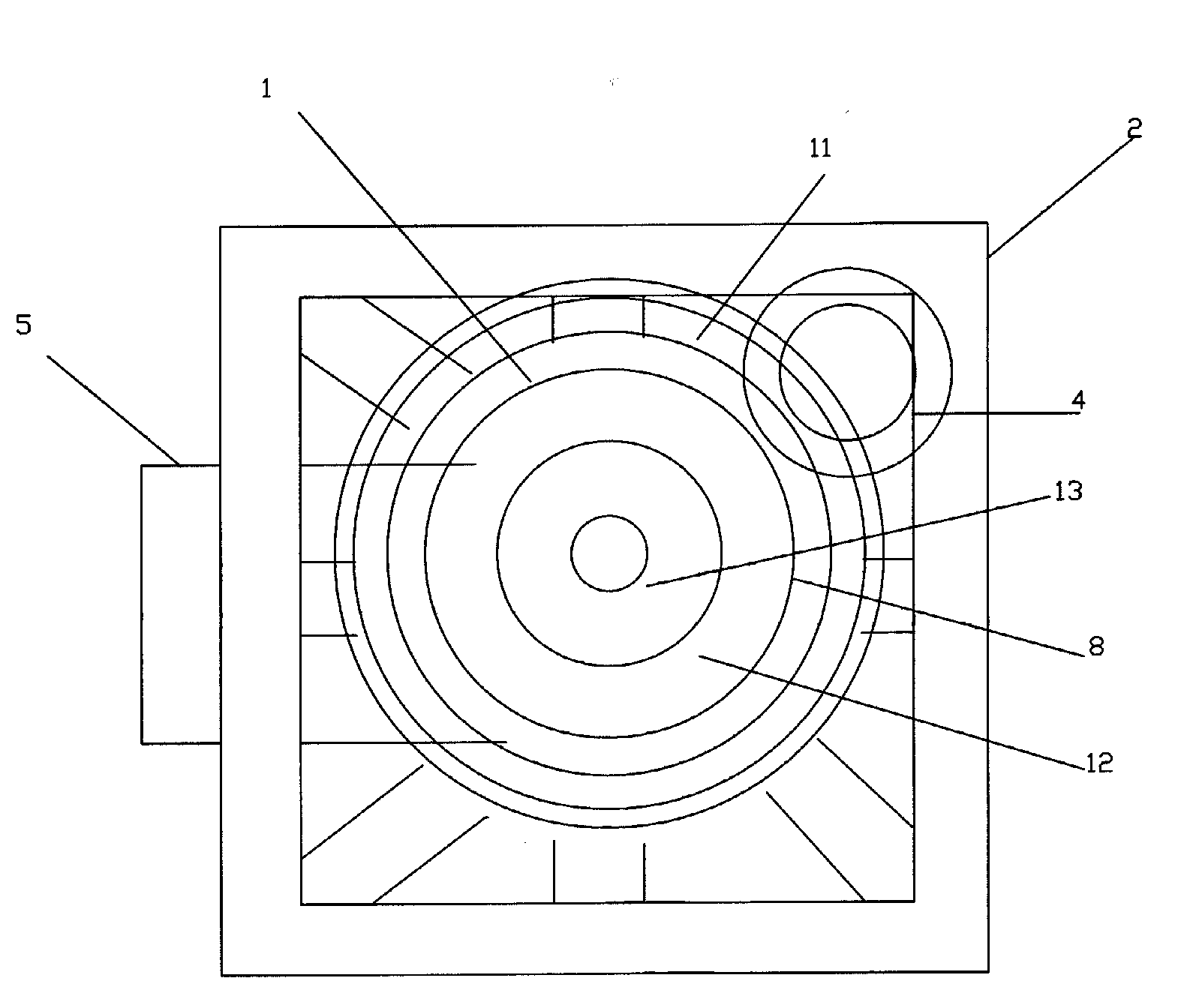

[0013] now attached figure 1 , 2 The present invention is explained in detail.

[0014] as attached figure 1 , 2 As shown, the vertical dryer of the present invention includes: a feed hopper 1, a frame 2, a rotary feeding chamber 3, a drive motor 4, a discharge port 5, and an internally fixed drying chamber 6; wherein, the feed hopper 1 Located at the top of the frame 2, it is funnel-shaped, and its lower end opening is connected with the rotary feeding chamber 3; The toothed plate 11, the rotating toothed plate 11 is driven by the driving motor 4 and rotates together with the entire rotary conveying chamber 3, and the iron ore concentrate in the rotating conveying chamber 3 is transported from top to bottom under the push of the screw pusher plate 10 , and discharge the dryer through the discharge port 5 at the lower end; the internal fixed drying chamber 6 is located inside the rotating material conveying chamber 3, and is a hollow cylindrical structure, which includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com