Anti-freezing device for air cooling island in power station

A technology of anti-freezing device and air-cooling island, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of large cooling air volume, freeze cracking of steam exhaust pipe radiators, easy to be blown off by wind, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

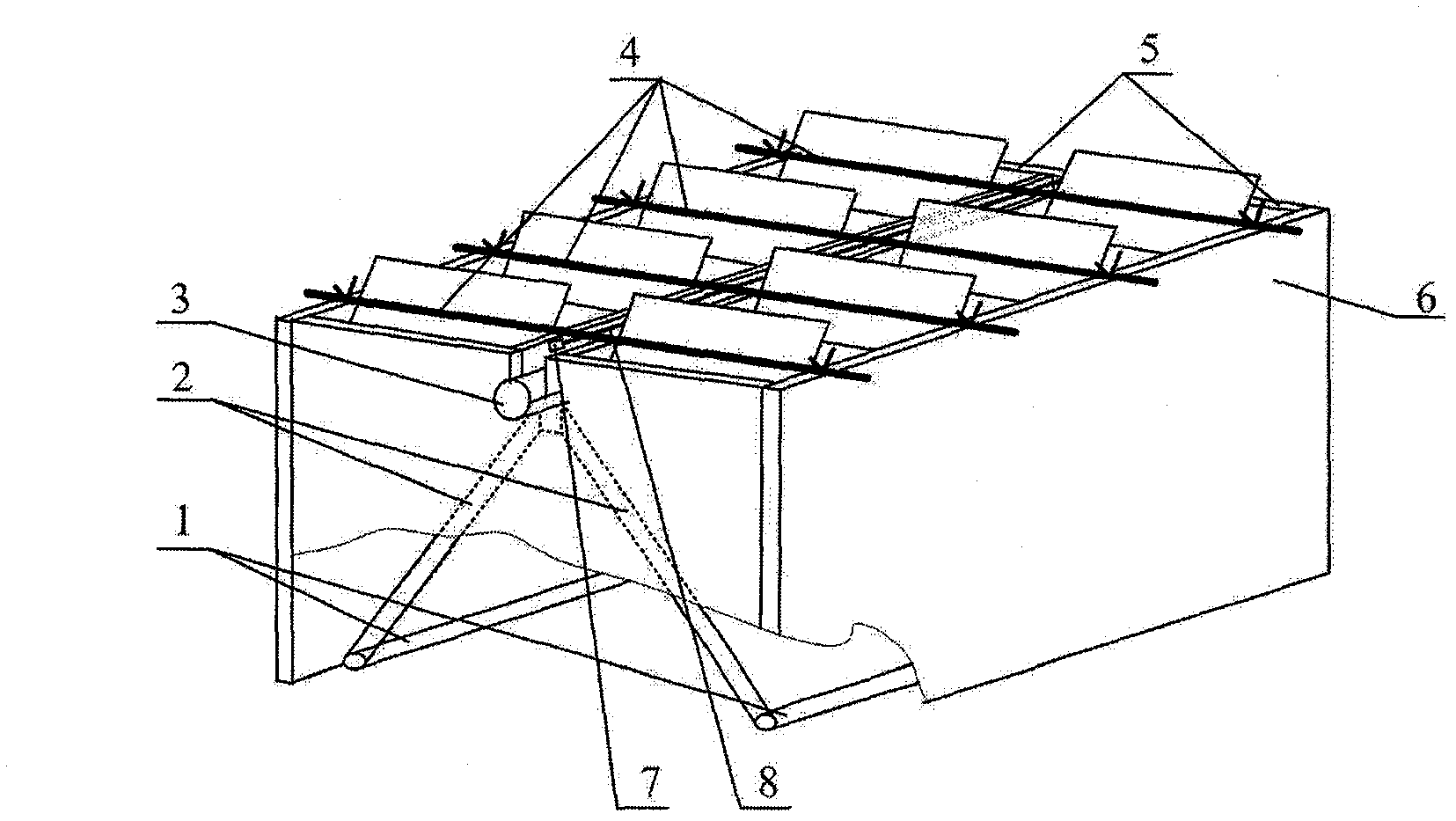

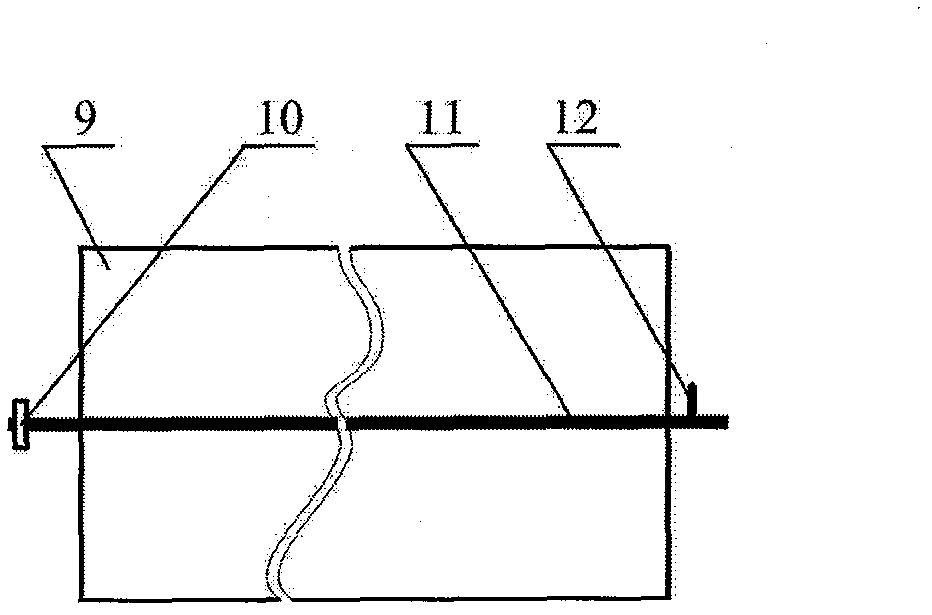

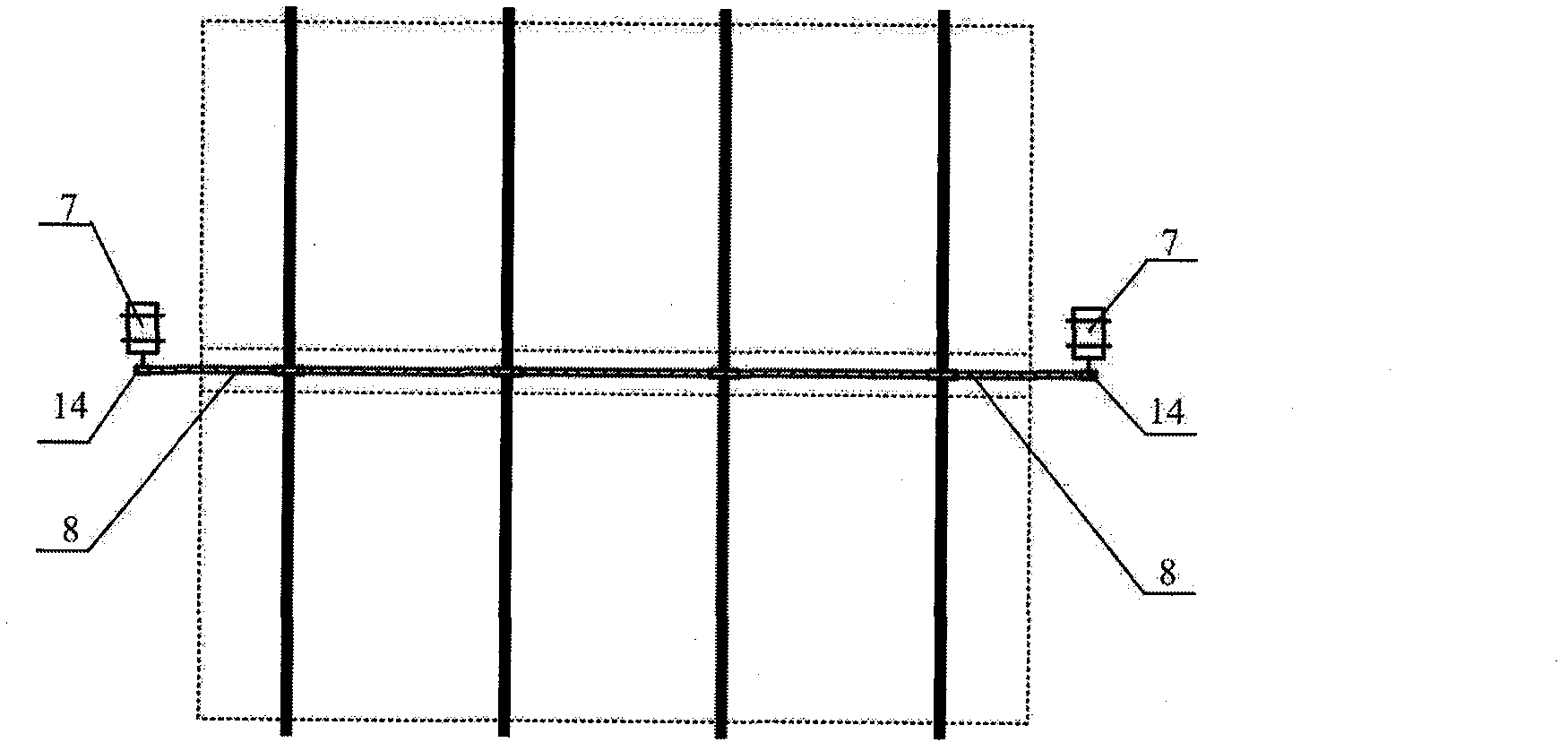

[0017] Such as figure 1 As shown, the exhaust steam discharged from the steam turbine is distributed to the steam calandria radiator 2 through the steam distribution pipe device 3 . The cold air enters from the bottom of the radiator, and flows through the heat dissipation gap between the steam pipes, absorbs the latent heat of the steam in the pipes, and flows out from the top of the radiator after the temperature rises. The exhaust steam condenses into water and enters the condensed water header 1. In order to do a good job of antifreezing the air-cooled island in winter, fixed windshields 5 and 6 are installed around the air outlet side of the air-cooled island steam pipe radiator, and a louvered windshield device 4 is installed above the pipe radiator , each louvered windshield is fixed on its shaft rod on the fixed windshield 6 through the axle sleeve 15, and each windshield can rotate around its own support shaft 11. In order to simplify the transmission device, a set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com