Deflector in condenser

A technology of condenser and baffle plate is applied in the field of baffle plate, which can solve the problems such as the influence of the cooling effect of the condenser, the poor quality of the cooling water, and the corrosion, so as to achieve the effect of ensuring the cooling effect, ensuring the normal use and improving the corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

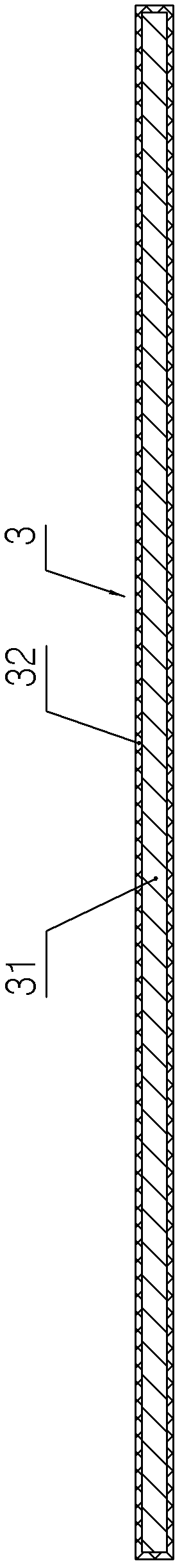

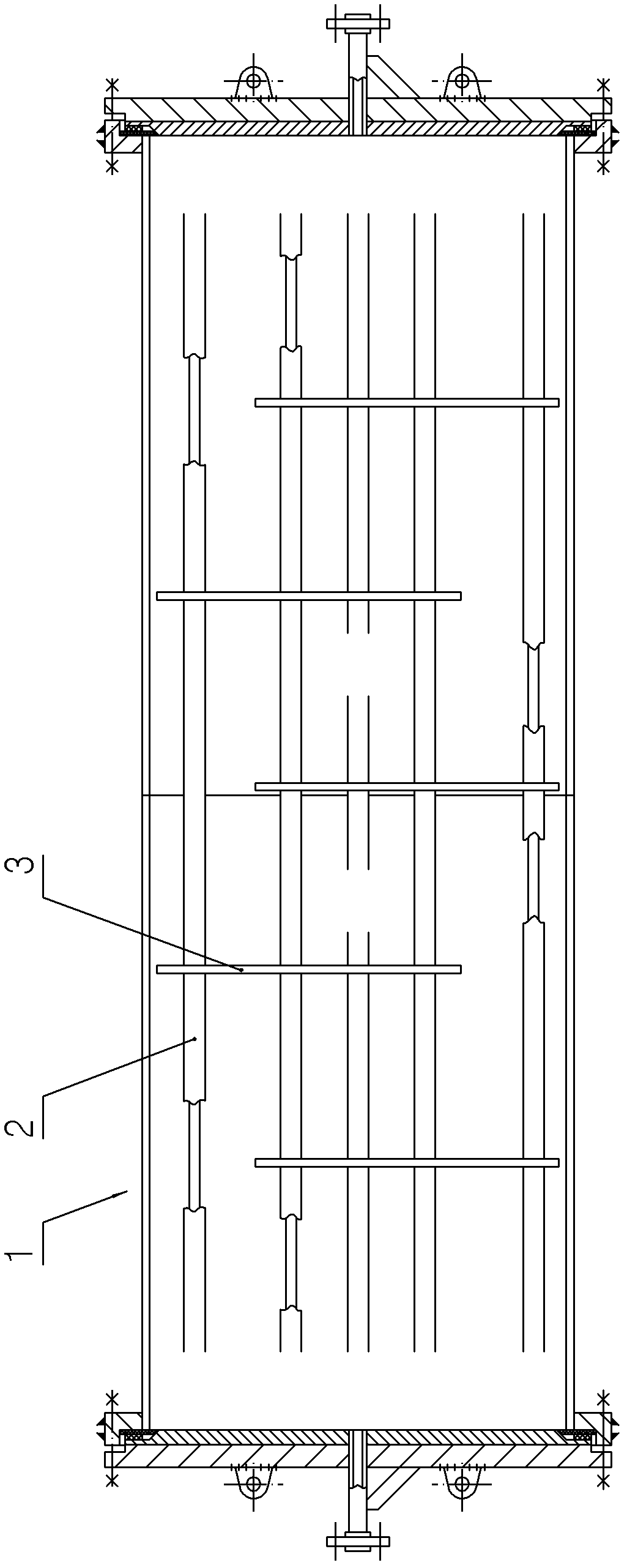

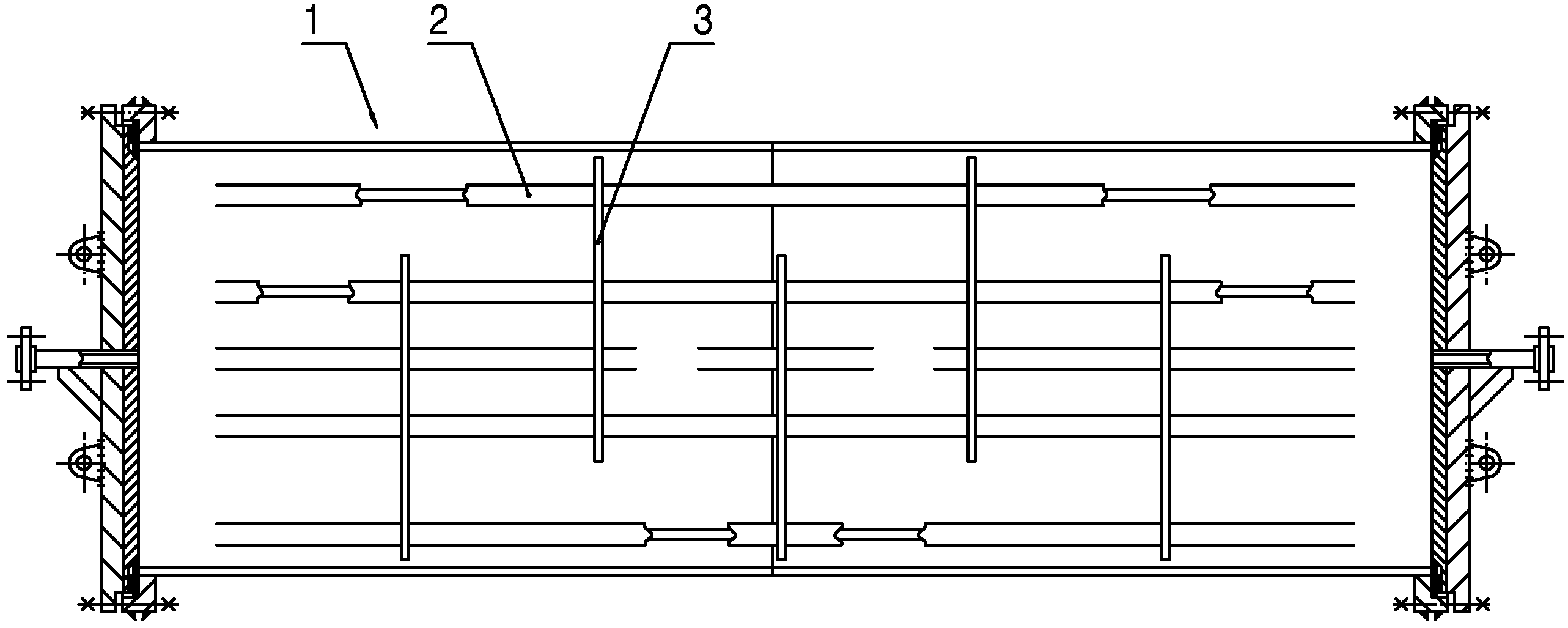

[0010] Such as figure 1 As shown, the baffle plate 3 in the condenser of the present invention includes: a metal substrate 31 provided with a tube hole matched with the heat exchange tube 2 in the condenser 1—see figure 2 As shown, the surface of the metal substrate 31 is coated with a corrosion-resistant layer 32 . In this embodiment, the metal substrate 31 is a stainless steel plate, and the corrosion-resistant layer 32 is made of polytetrafluoroethylene (commonly known as tetrafluoroethylene).

[0011] Certainly, the above-mentioned baffle plate 3 is a tetrafluoro plate, that is, a polytetrafluoroethylene plate, that is, the whole body is made of polytetrafluoroethylene. In this case, although the corrosion resistance is reliably guaranteed, the manufacturing cost is increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com