MEMS (micro-electromechanical system) thermal-type flow sensor

A thermal flow sensor technology, applied in the field of flow sensors, can solve problems such as air flow disorder and affect the accuracy of detection results, and achieve the effects of enhanced anti-pollution ability, long service life, and elimination of measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

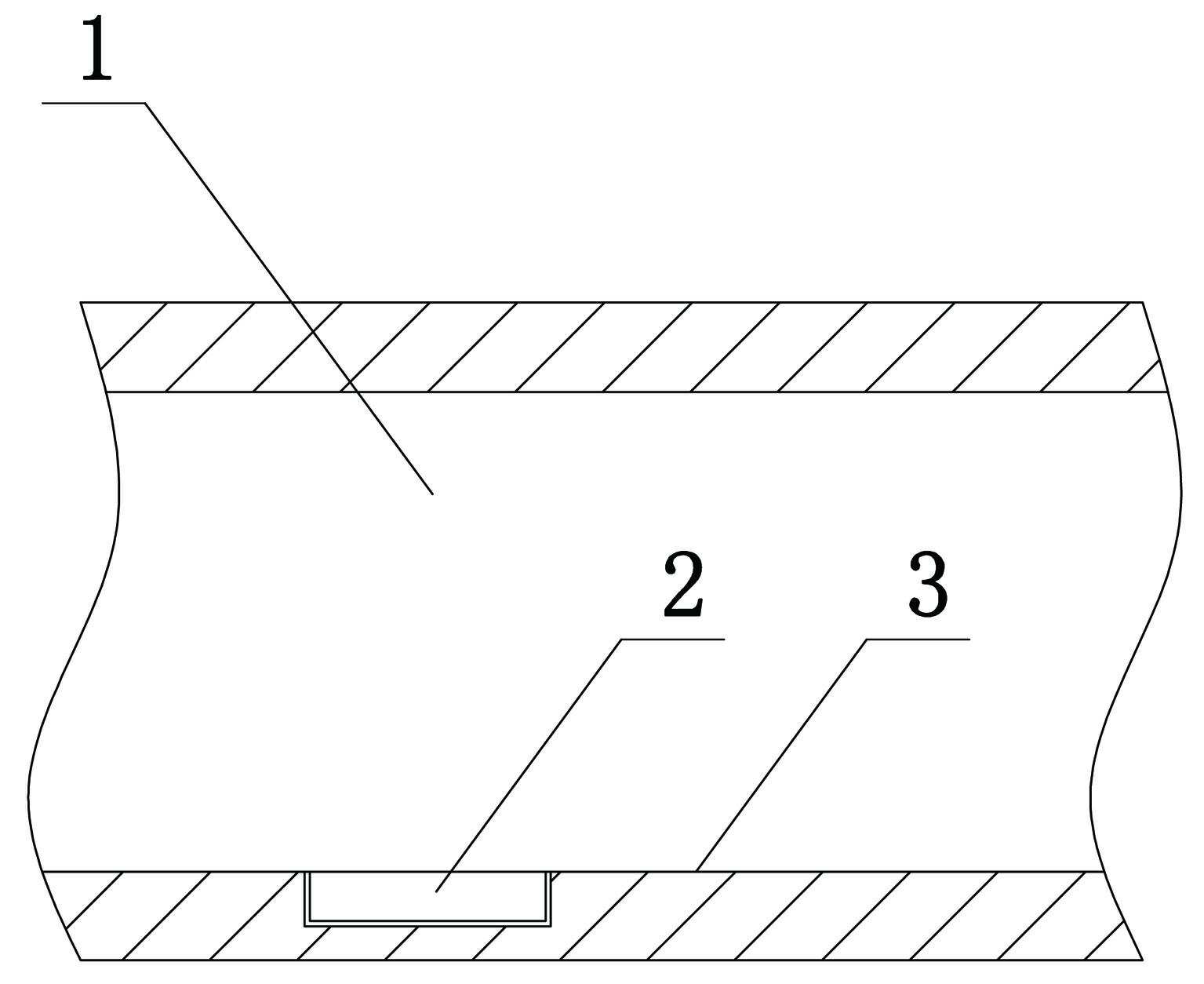

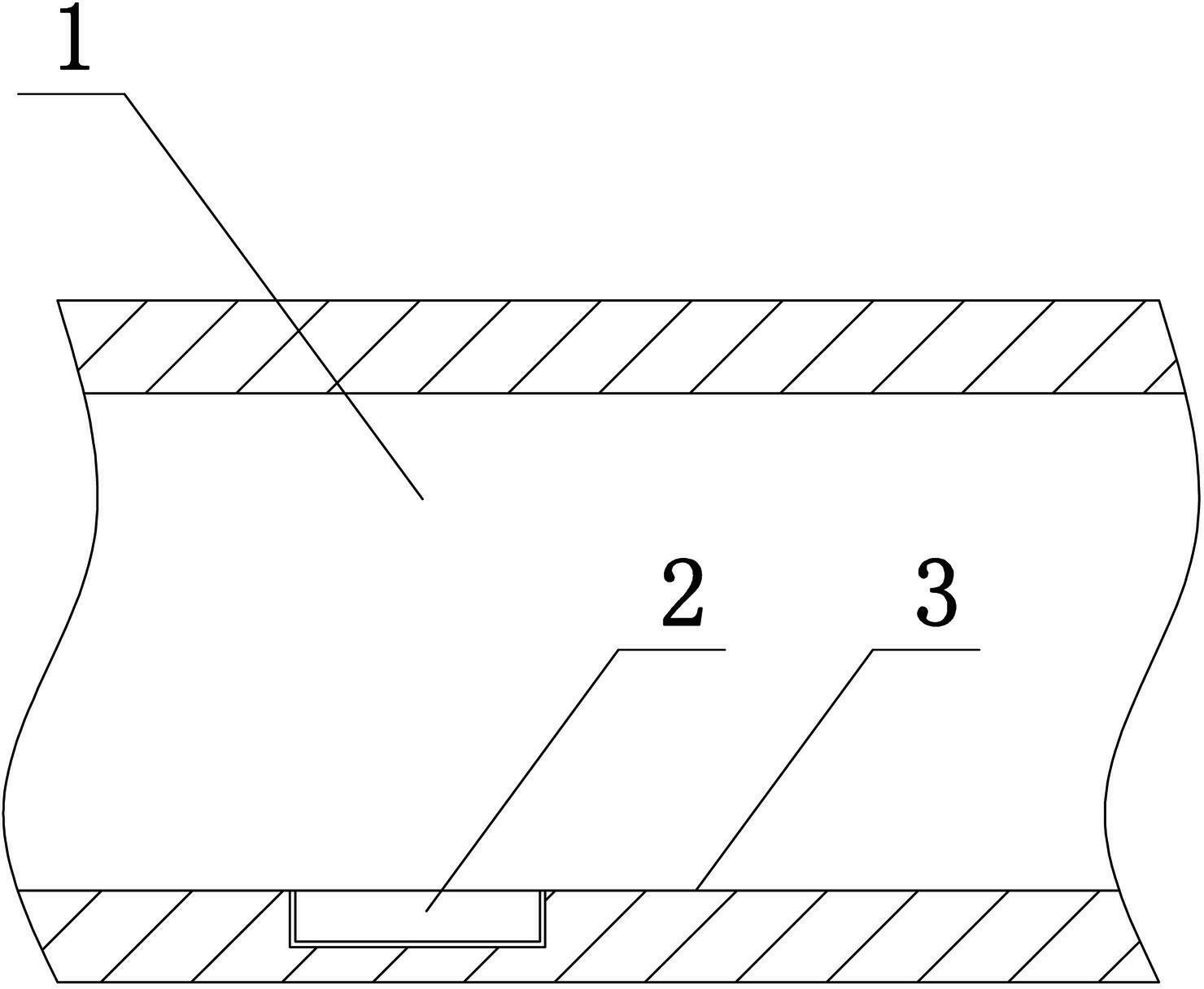

[0012] Such as figure 1 Shown, a kind of MEMS thermal flow sensor, it comprises MEMS thermal flow sensing chip 2 and fluid channel 1; Wherein, described fluid channel 1 has the side inner wall of groove is smooth plane inner wall; Described fluid channel The inner wall 3 of 1 is provided with a groove, and the shape and size of the groove match the shape and size of the MEMS thermal flow sensing chip 2; the MEMS thermal flow sensing chip 2 is mounted on the In the groove, the sensitive surface of the MEMS thermal flow sensing chip 2 is flush with the surface of the inner wall 3 of the fluid channel 1; it should be noted that, in other embodiments, the groove can also be A slot is used to install the MEMS thermal flow sensing chip 2 from the outside of the fluid channel 1 .

[0013] Mount the same MEMS thermal flow sensing chip in the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com