Method for calibrating surface temperature of metal flat plate

A technology of flat metal and surface temperature, which is applied in the field of product development and heat treatment of cold-rolled metal strips, can solve problems such as inaccuracy and interference, and achieve the effect of accurate temperature measurement, simple method and convenient realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0047] A method for calibrating the surface temperature of a flat metal plate. The method uses a constant temperature bath medium as a heating source to heat one side of the flat metal plate to be tested, and installs a plurality of direct-contact heat-sensitive elements on the surface to measure the temperature of the flat metal plate to be tested; On the other side of the metal plate, use a non-contact temperature measuring instrument to measure the surface temperature of the metal plate to be tested;

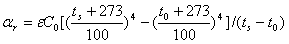

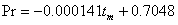

[0048] According to the temperature measurement principle of the infrared temperature measuring instrument, Stephen-Boltzmann's law, the surface emissivity of the metal plate to be tested is calculated; the Stephen-Boltzmann's law is that the relationship between the radiation energy W of a black body and its temperature T is W= ε*σ*T 4 , where Bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com