Device and method for preparing electrochemical corrosive sample

A technology for corrosion samples and preparation devices, which is applied in the field of corrosion performance research of metal materials, can solve problems such as complicated structures, and achieve the effects of simple procedures and saving sample preparation time and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] specific implementation plan

[0020] The specific implementation scheme of electrochemical corrosion sample preparation for the stainless steel material of the pump body of the LNG filling station is as follows.

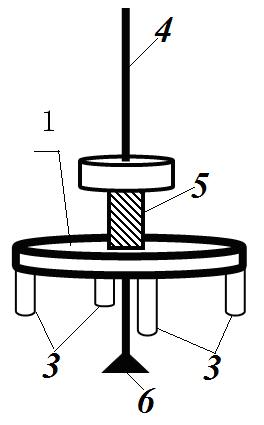

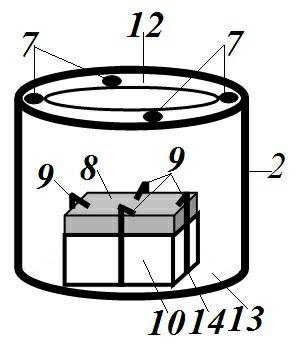

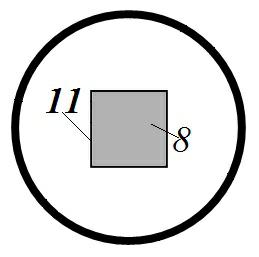

[0021] Cut the stainless steel material of the pump body of the LNG filling station into a cuboid sample 8, grind the working surface 14 of the stainless steel sample 8 to 1200# with sandpaper and polish it; In the polyethylene cover 10 inside the main body 2, the sample 8 is tightly fixed by four elastic pieces 9 on the outer periphery, so that the working surface 14 is attached to the 1mm×1mm hollow window 11 on the lower surface 13 of the polyethylene main body. Align the four pillars 3 on the polyethylene cover 1 with the four holes 7 on the polyethylene body 2 and cover them tightly, and rotate the screw 5 on the polyethylene cover 1 to drive the copper wire 4 to move towards the lower surface 13 of the polyethylene body , until the flat copper wire end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com