Method for measuring ultrasonic attenuation coefficient of solid material

A solid-state material and attenuation coefficient technology, which is used in the analysis of solids using sonic/ultrasonic/infrasonic waves. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

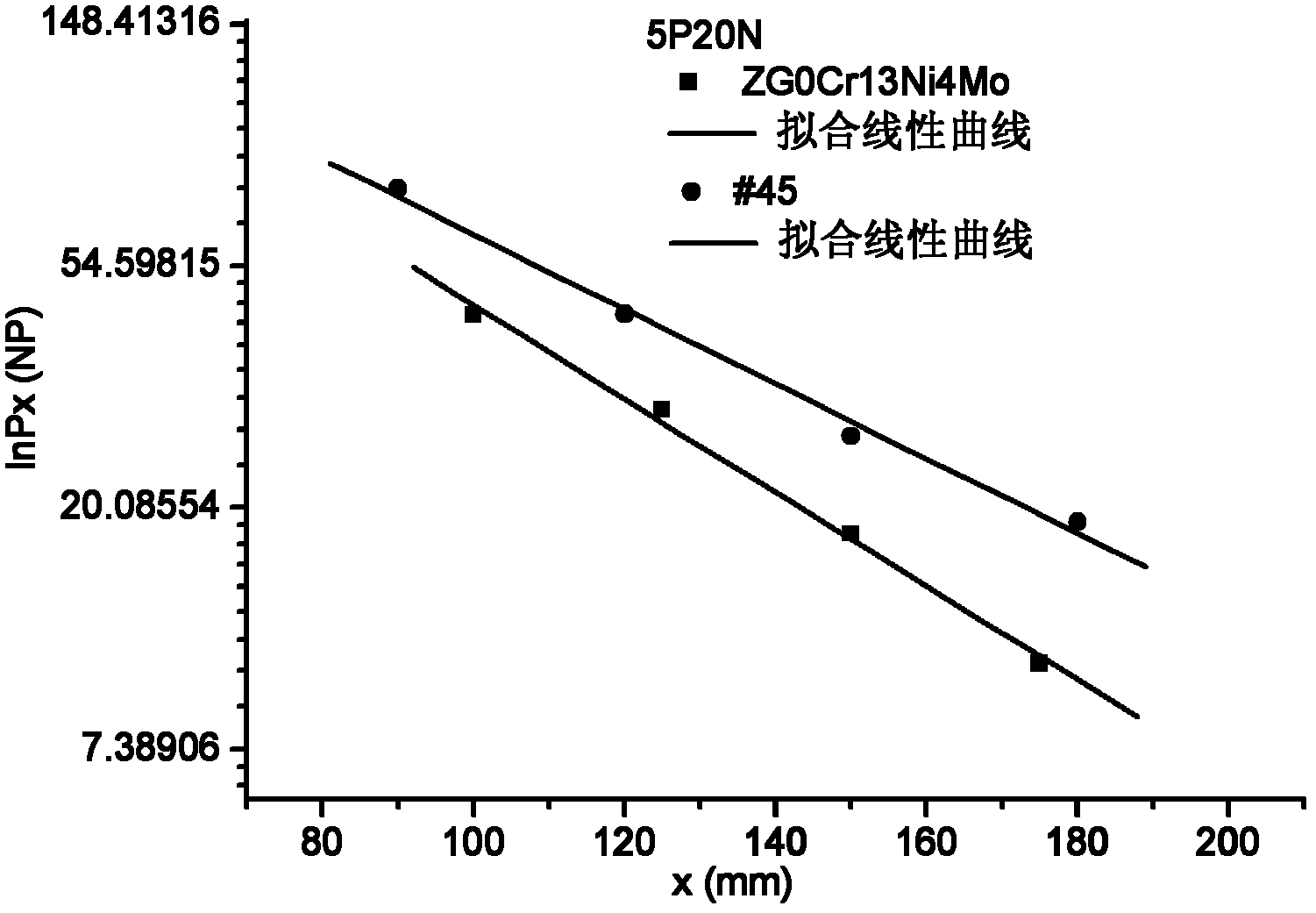

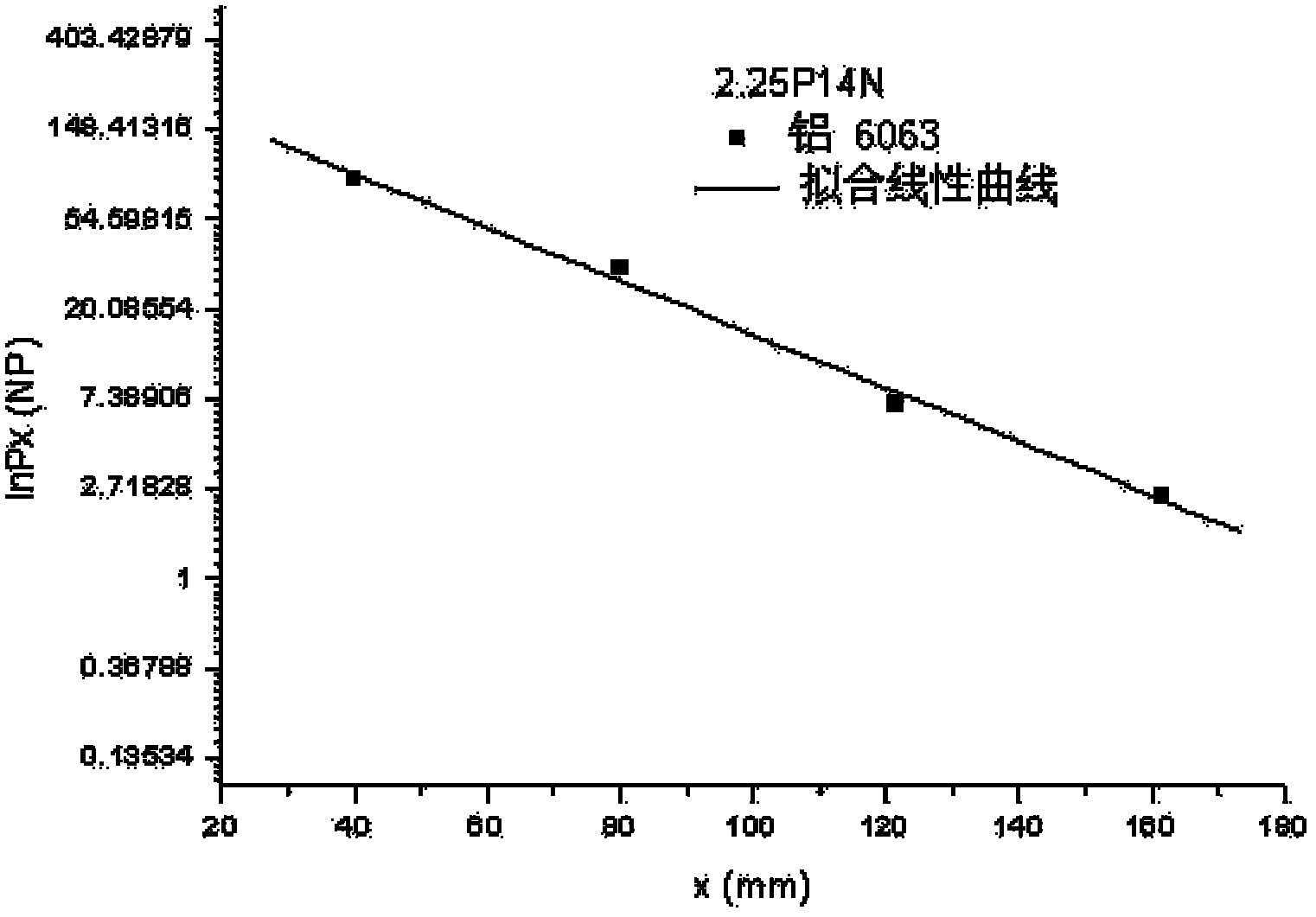

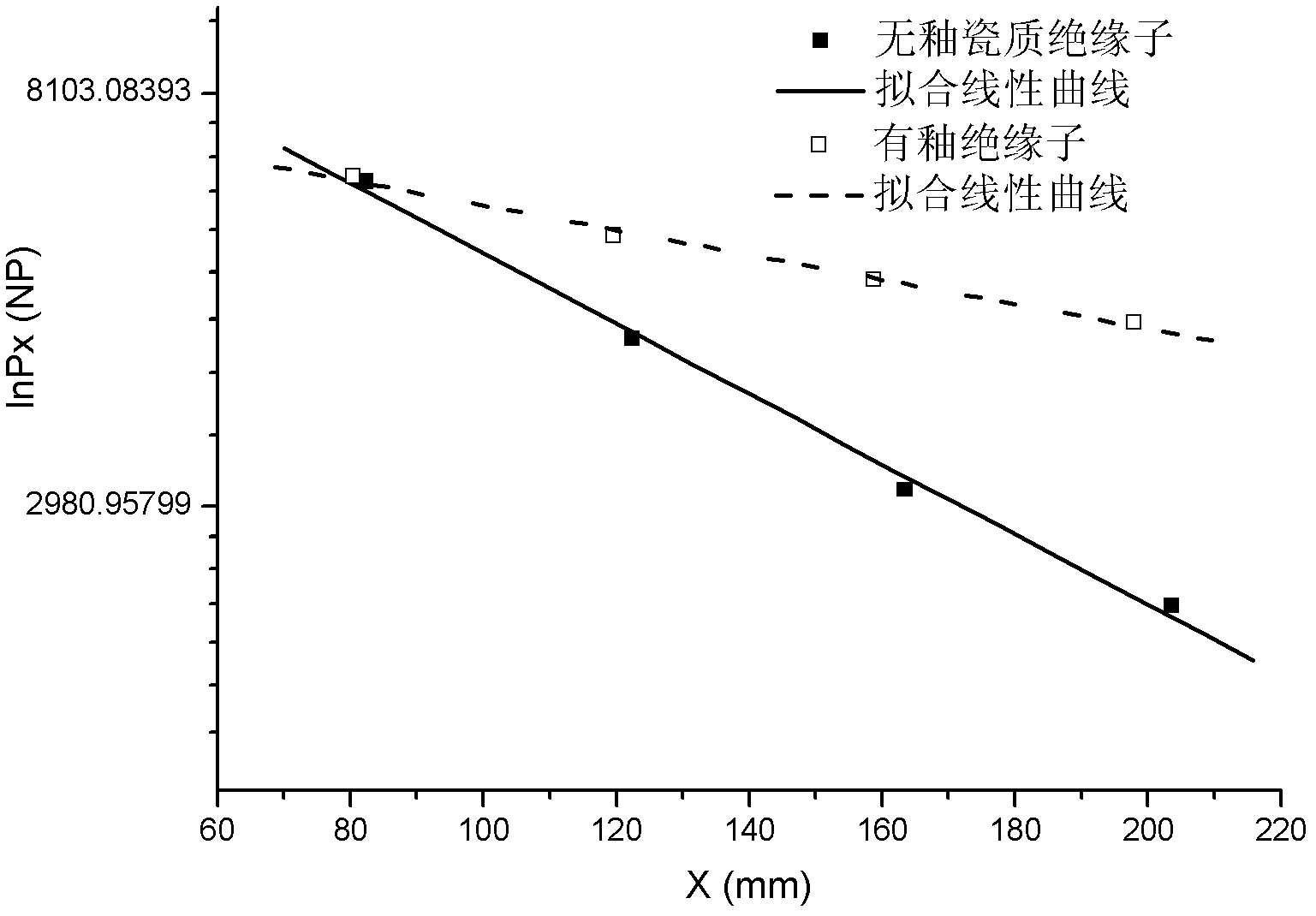

[0017] The method for measuring the ultrasonic attenuation coefficient of solid material of the present invention is carried out according to the following steps:

[0018] 1. Select solid materials that need to be measured with different materials and specifications as samples. For example, the material is No. 45 steel, and the specification is 200×160×30mm (length×width×thick); ZG0Cr13Ni4Mo martensitic stainless steel, the specification is 160×100× 25mm (length × width × thickness); 6063 grade aluminum alloy material, thickness 40mm; unglazed porcelain insulator material, thickness 41mm; glazed porcelain insulator material, thickness 40mm;

[0019] 2. The test instrument is the Hanwei HS616 produced by Wuhan Zhongke Innovation Technology Co., Ltd. The probe is a type A pulse reflection reflection longitudinal wave straight probe, the coupling agent is engine oil, and the surface compensation is 0dB. Use the materials to be measured in step 1 respectively. The prepared standar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com