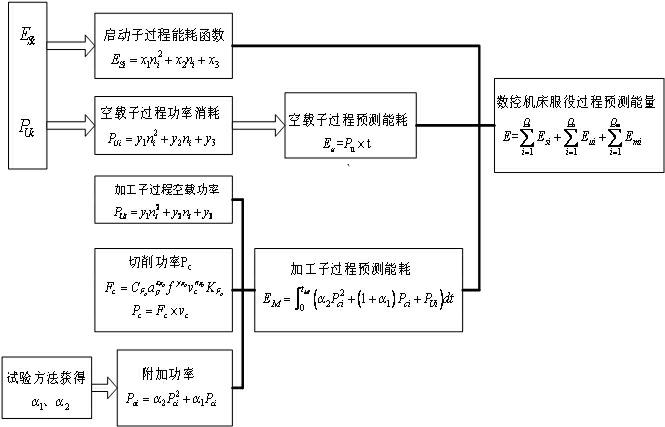

Energy consumption prediction method for use in service process of numerically-controlled machine tool

A technology of energy consumption and prediction method, applied in the direction of program control, computer control, general control system, etc., can solve the problems of many influencing factors, prediction of energy consumption of CNC machine tools, and failure to consider the power loss of additional load of machine tools, etc. The application prospect and the effect of the method are simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

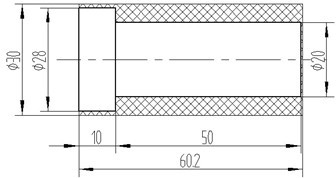

[0081] On the CNC lathe of C2-6136HK / 1, the method of the present invention is used to predict the energy consumption during its service process, and the process is as follows:

[0082] 1) Obtain the basic data of the CNC lathe of C2-6136HK / 1:

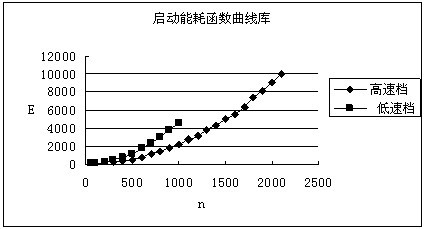

[0083] According to the energy consumption prediction method proposed by the present invention, to predict the energy consumption of any service process of the C2-6136HK / 1 CNC lathe with two speeds (Table 1), it is necessary to prepare in advance the start-up process energy consumption function library, empty load process power function library, and solve basic parameters , .

[0084] Table 1 C2-6136HK / 1 CNC lathe parameters

[0085]

[0086] According to the method described in step 3 of the implementation method, select the speed points at all levels, and measure the starting energy consumption such as image 3 Shown, and fit the low-speed gear start energy consumption function and high-speed start energy consumption funct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com