Method for analyzing load and stress distribution and stress levels of composite mechanical connection pins

A technology of mechanical connection and composite materials, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems of complex modeling process, short calculation period, long calculation period, etc., to improve calculation efficiency and ensure calculation. The effect of precision, short calculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

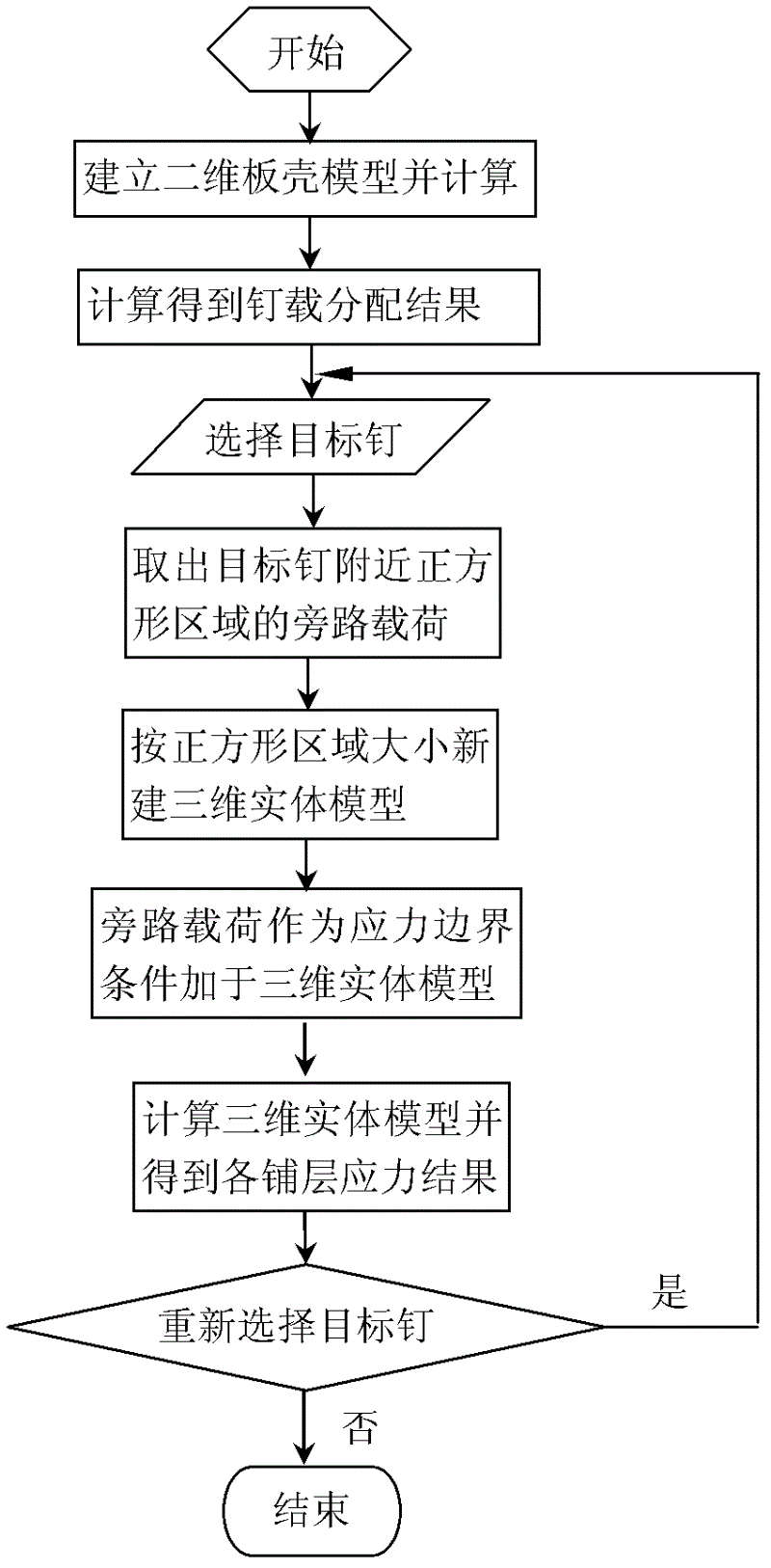

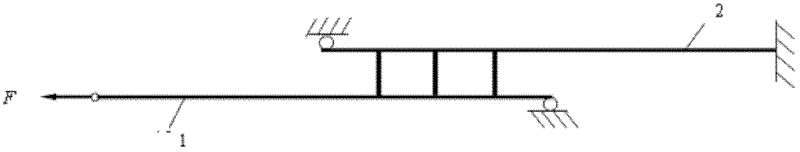

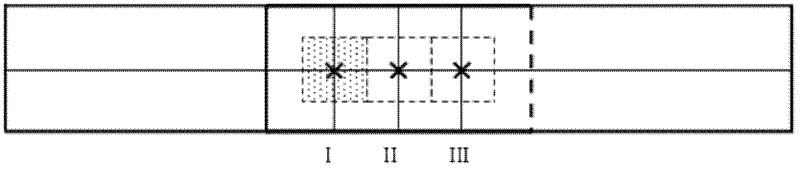

[0037] The calculation process of the present invention is as figure 1 As shown, in order to better understand the technical solution of the present invention, the above algorithm is applied to the common analysis of the mechanical connection between the composite material plate and the metal plate. The analysis content is: nail load distribution calculation, and stress field analysis around the maximum nail load hole . The connector is a single lapped plate with three nails, as shown in Figure 2. The following steps are based on the finite element software ANSYS:

[0038] Step 1. According to the actual length and width of different plates to be connected, establish a geometric surface at the position of the respective middle plane, move the origin of the working plane to the position of the nail, rotate the working plane, and move the plane along the X directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com