Write-once optical recording medium and process for manufacturing the same

A technology of an optical recording medium and a manufacturing method, which is applied in the directions of optical recording medium, recording/reproducing by optical method, data recording, etc., can solve the problems of difficult storage reliability and productivity, low productivity, low film deposition rate, etc., Achieves good storage reliability, improved productivity, and high film deposition rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0038] (1-1) Structure of write-once optical recording medium

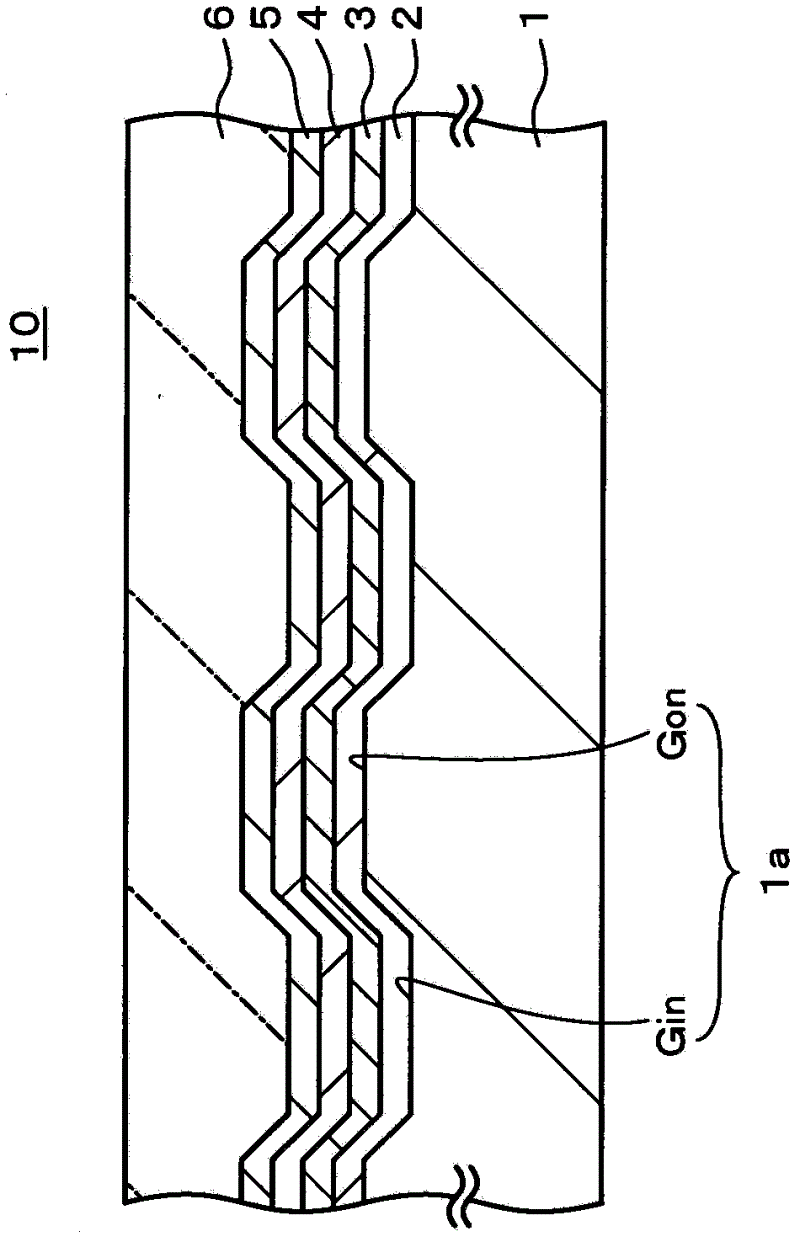

[0039] figure 1 is a schematic sectional view showing a configuration example of the write-once optical recording medium according to the first embodiment of the present invention. The write-once optical recording medium 10 has a configuration in which a reflective layer 2, a first protective layer 3, an inorganic recording layer 4, a second protective layer 5, and a light-transmitting layer 6 are sequentially laminated on a substrate 1. superior.

[0040] In this write-once optical recording medium 10 according to the first embodiment, recording or reproduction of an information signal is performed by irradiating the inorganic recording layer 4 with a laser beam from the light-transmitting layer 6 side. For example, by condensing a laser beam having a wavelength in the range of 400 nm to 410 nm with an objective lens having a numerical aperture in the range of 0.84 or more and 0.86 or less, and irradiating the ...

no. 2 approach

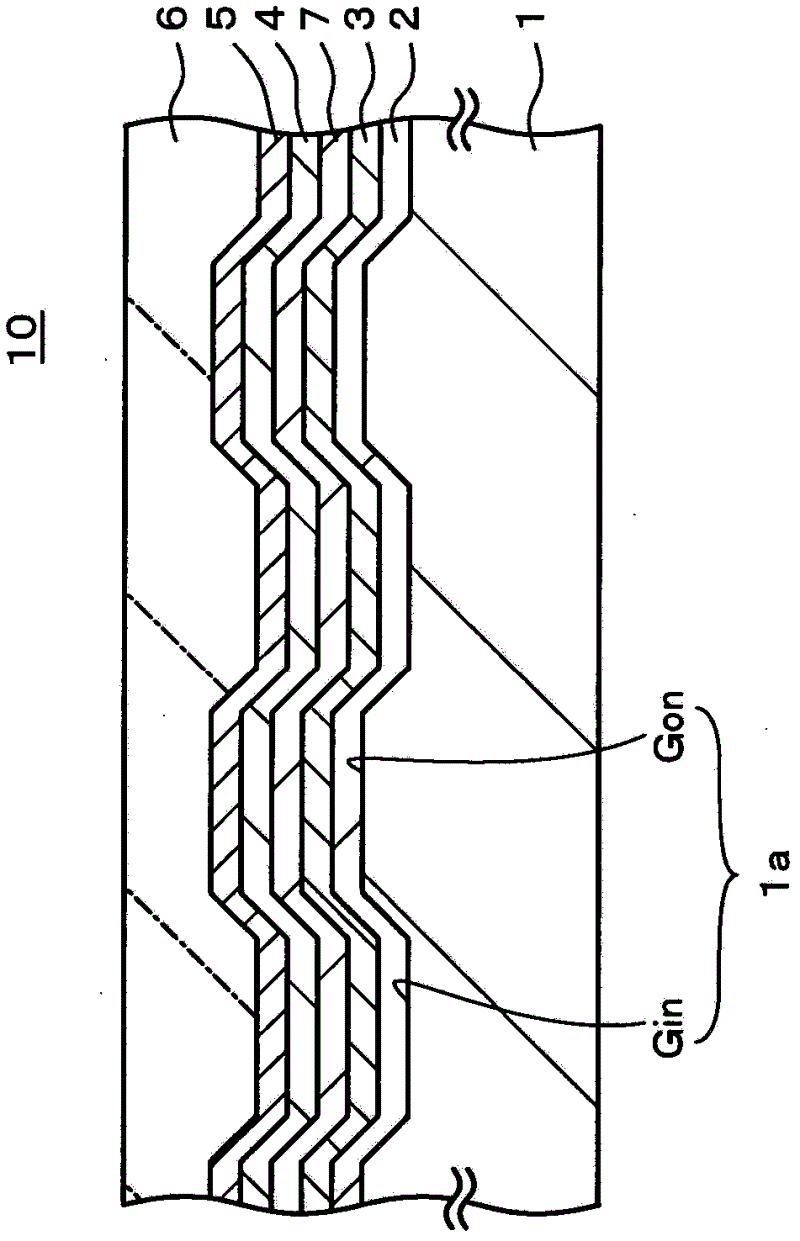

[0084] figure 2 is a schematic sectional view showing a configuration example of a write-once optical recording medium according to a second embodiment of the present invention. It should be noted that the same components as those of the write-once optical recording medium according to the first embodiment are denoted by the same reference numerals, and descriptions of these components will be omitted. Such as figure 2 As shown, the write-once optical recording medium 10 according to the second embodiment is different from the write-once optical recording medium 10 according to the first embodiment in that further between the first protective layer 3 and the inorganic recording layer 4 A heat accumulation layer 7 is provided. The heat accumulation layer 7 contains, for example, ZnS-SiO 2 etc. as the main component of the dielectric material. From the standpoint of improving the recording power margin, the thickness d of the second protective film 5 is preferably 11 nm to...

no. 3 approach

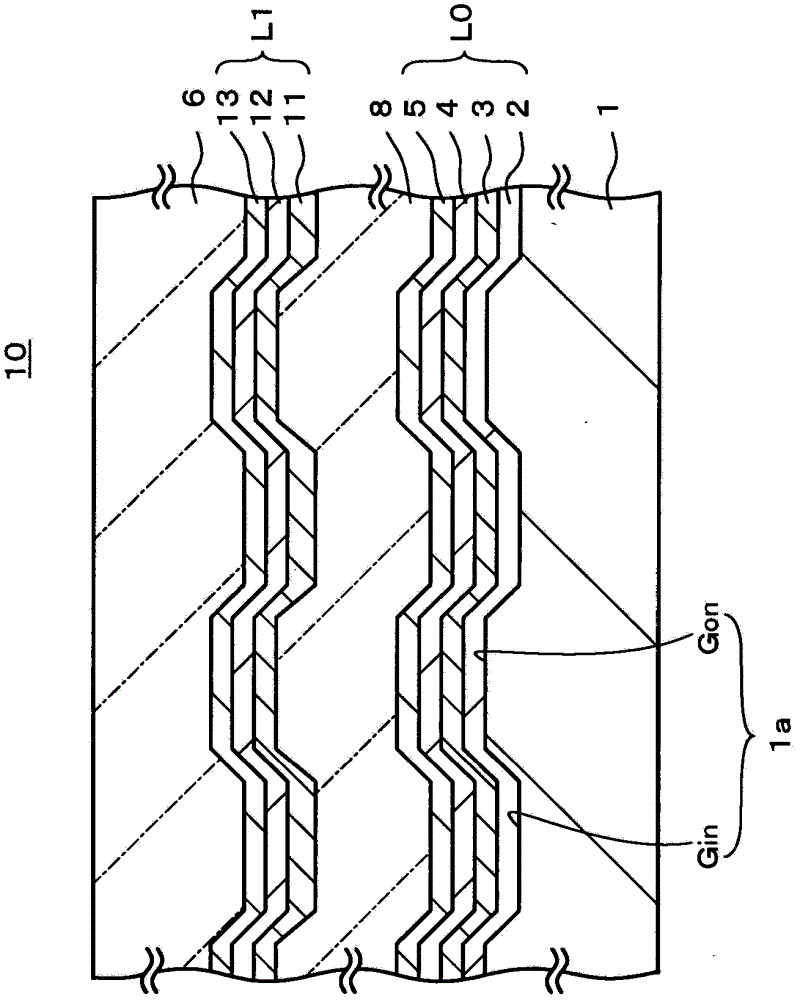

[0090] (3-1) Structure of write-once optical recording medium

[0091] image 3 is a schematic sectional view showing a configuration example of a write-once optical recording medium according to a third embodiment of the present invention. It should be noted that the same components as those of the write-once optical recording medium according to the first embodiment are denoted by the same reference numerals, and descriptions of these components will be omitted. Such as image 3 As shown, the write-once optical recording medium 10 has a structure in which a first recording layer (L0 layer) L0, an interlayer (interlayer) 8, a second recording layer (L1 layer) L1 and optical The transmissive layer 6 is sequentially laminated on the substrate 1 . The first recording layer L0 is a configuration in which a reflective layer 2 , a first protective layer 3 , an inorganic recording layer 4 , and a second protective layer 5 are sequentially laminated on a substrate 1 . The second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com