Magnetic shielding forming line equipment for transformer

A magnetic shielding, forming wire technology, applied in the manufacture of inductors/transformers/magnets, preventing/reducing unwanted electrical/magnetic effects, electrical components, etc., can solve imperfect equipment, low production efficiency, high labor intensity, etc. problems, to achieve the effect of balanced production rhythm, easy operation and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

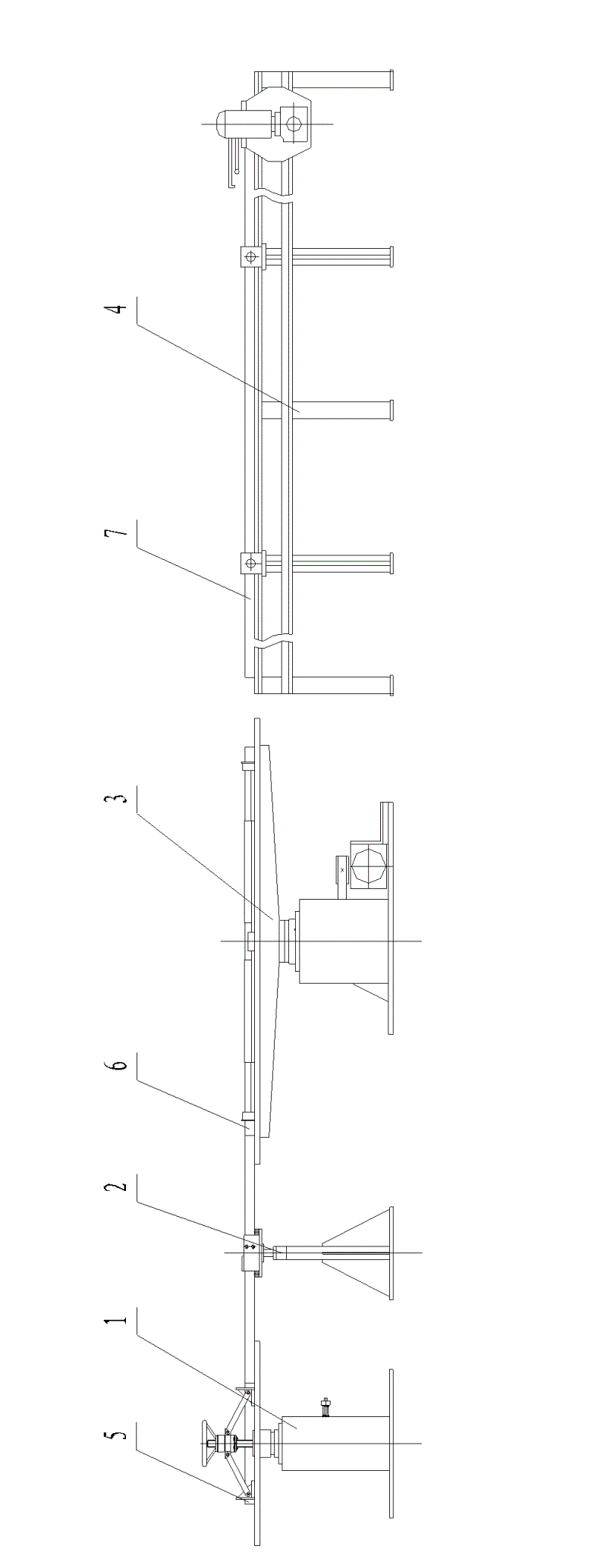

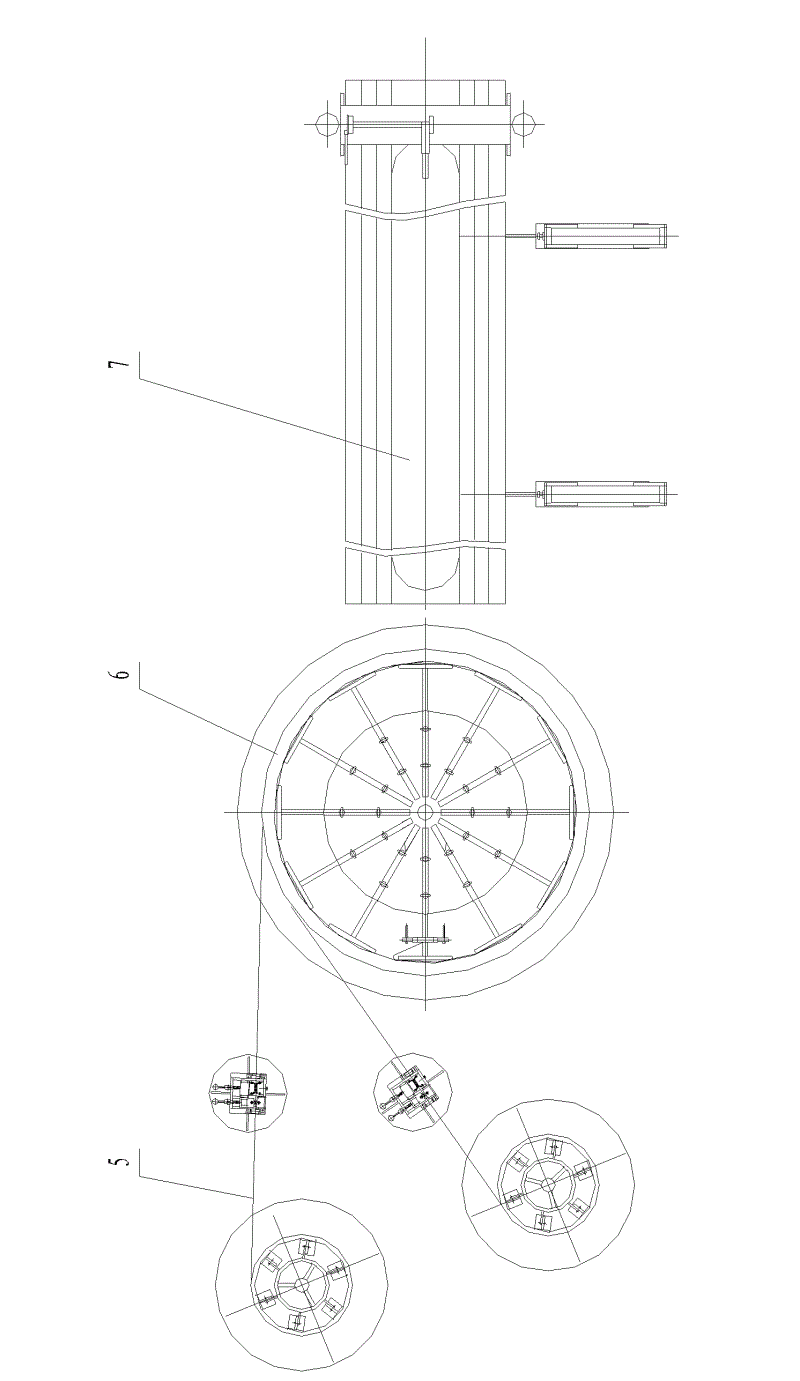

[0029] Such as figure 1 As shown, the present invention includes a discharging machine 1, a clamping device 2, a winding machine 3 and a compression forming machine 4 arranged in sequence.

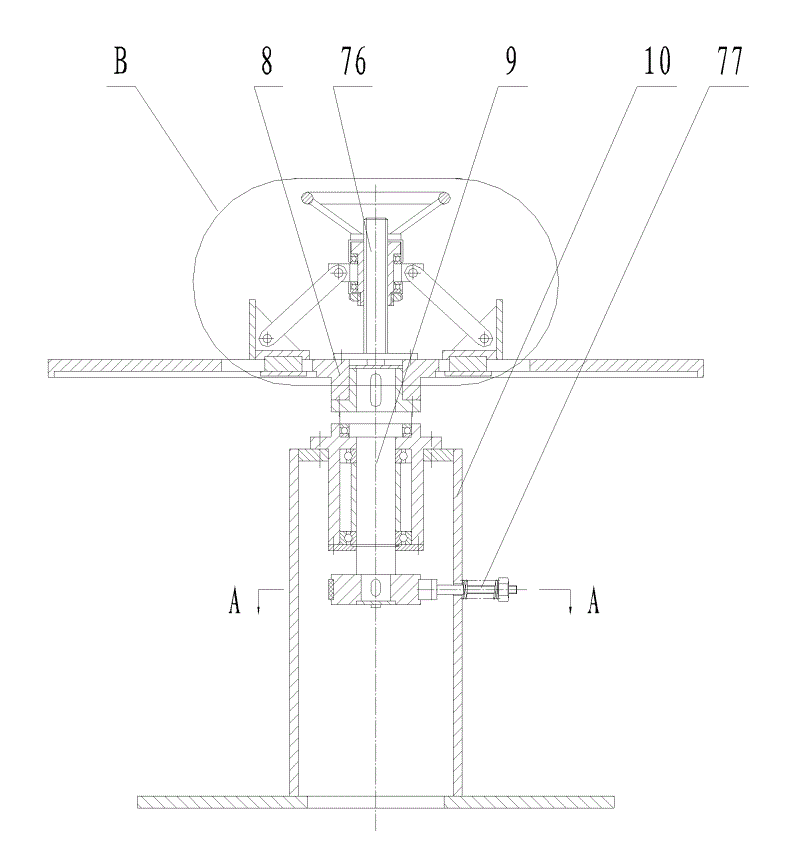

[0030] Such as Figure 3-5As shown, the discharge machine 1 includes a workbench 8, a discharge machine spindle device 9, a column 10, a tensioning device 76 and a brake device 77, wherein the discharge machine spindle device 9 includes a spindle, a bearing and a bearing seat, and the column 10 is Hollow structure, the bearing seat is located in the column 10 and fixed to the top of the column 10, the main shaft is rotatably installed in the bearing seat through the bearing, one end (lower end) of the main shaft is provided with a brake device 9, and the other end (top) is connected to the working Station 8 is fixedly connected. The tensioning device 76 is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com