Baffle type wind-pressure switch

A wind pressure switch and baffle-type technology, which is applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of non-maintenance, shutdown of the whole machine, action hysteresis and failure, etc., and achieve long service life, simple structure, and easy operation. reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing.

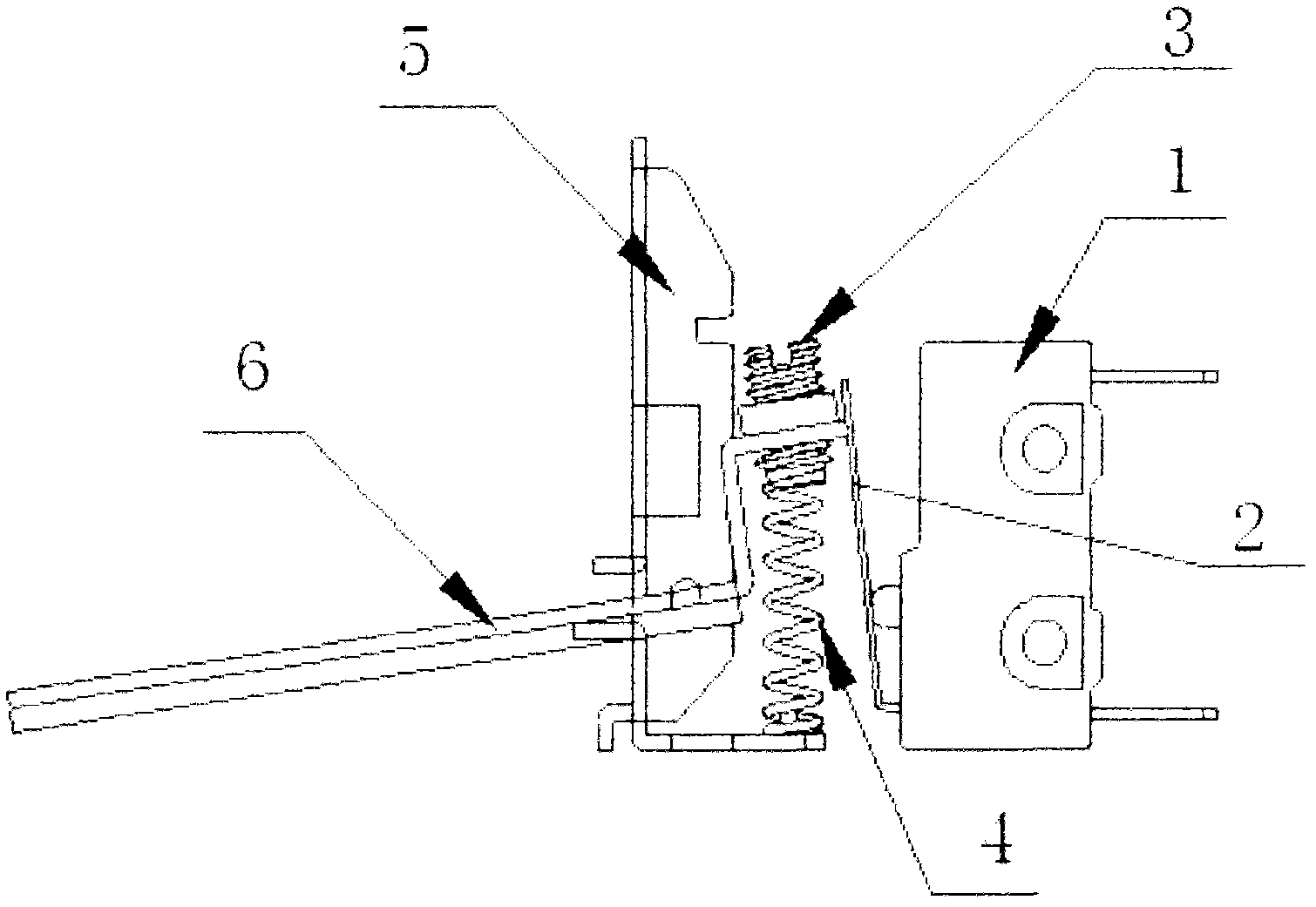

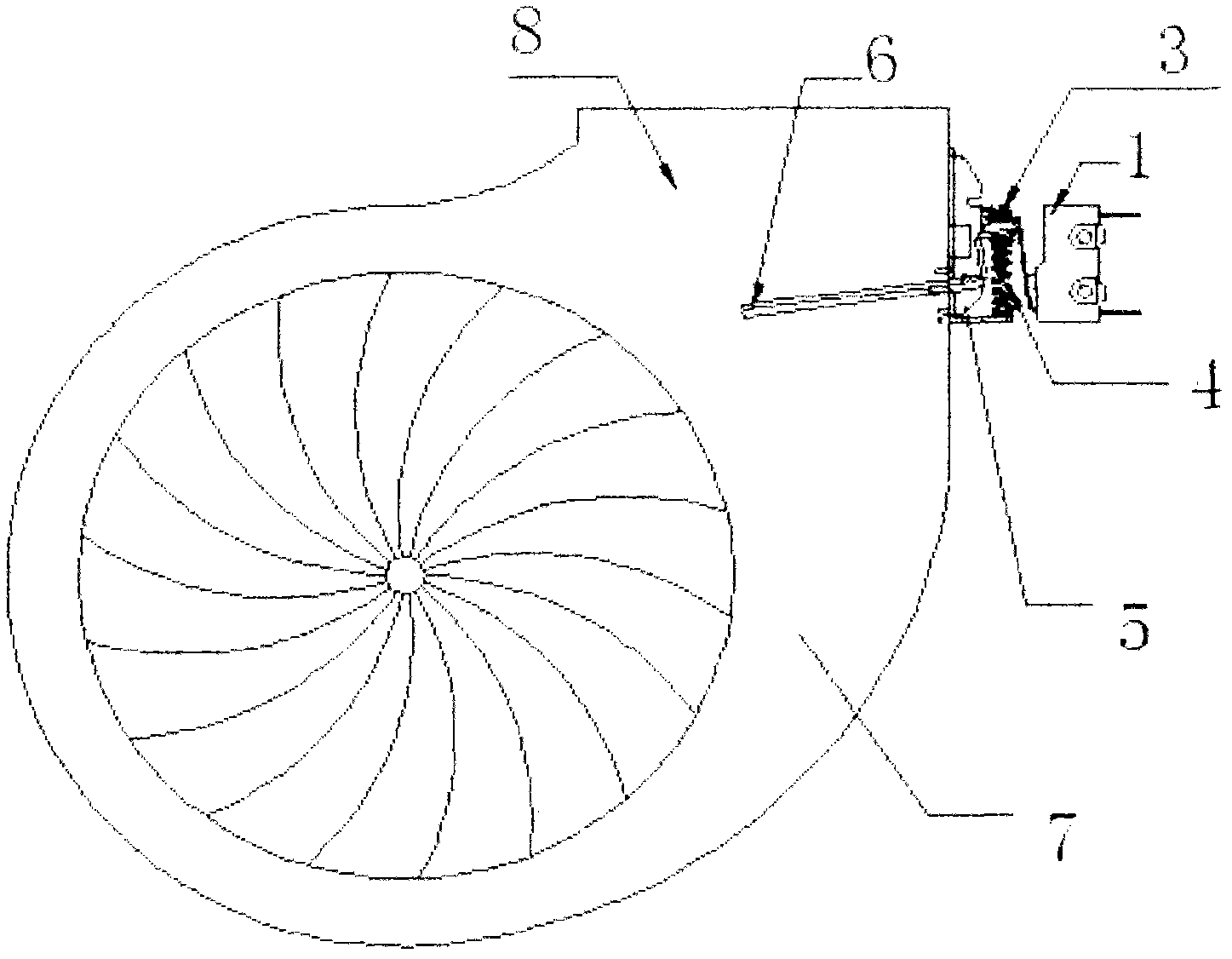

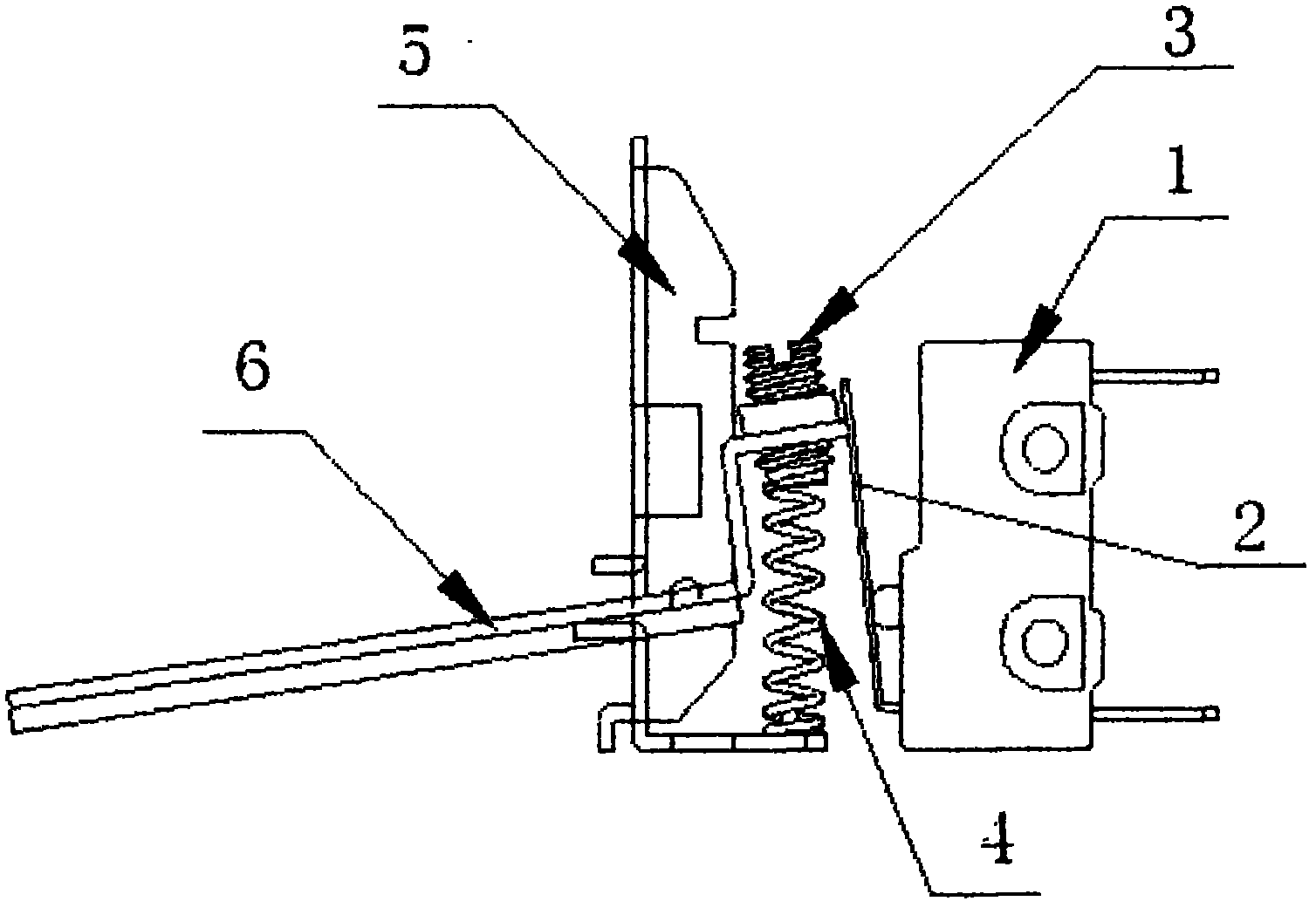

[0010] refer to figure 1 and 2 , the baffle type air pressure switch of the present invention includes a support 5, on which a wind pressure baffle 6 is hinged, and the corner plate end of the wind pressure baffle 6 is connected with a pressure regulating screw 3, and the pressure regulating screw 3 is connected to the The homing pressure-regulating spring 4 provided on the support 5 cooperates, and the contact plate 2 of the micro switch 1 contacts and cooperates with the corner extreme surface of the wind pressure baffle 6 . When in use: fix the support 5 of the baffle type air pressure switch on the side wall of the air outlet end of the fan 7, and the air pressure baffle 6 is directly inserted into the air outlet 8 of the fan from the side wall of the fan 7.

[0011] The specific implementation of the baffle-type wind pressure switch of the present invention is not li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com