Discharging template of bulking machine

A technology for discharging templates and extruders, applied in feed, food forming, food science, etc., can solve problems such as low production capacity and inability to realize large-scale production, and achieve the effects of reducing formula cost, facilitating cutting, and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

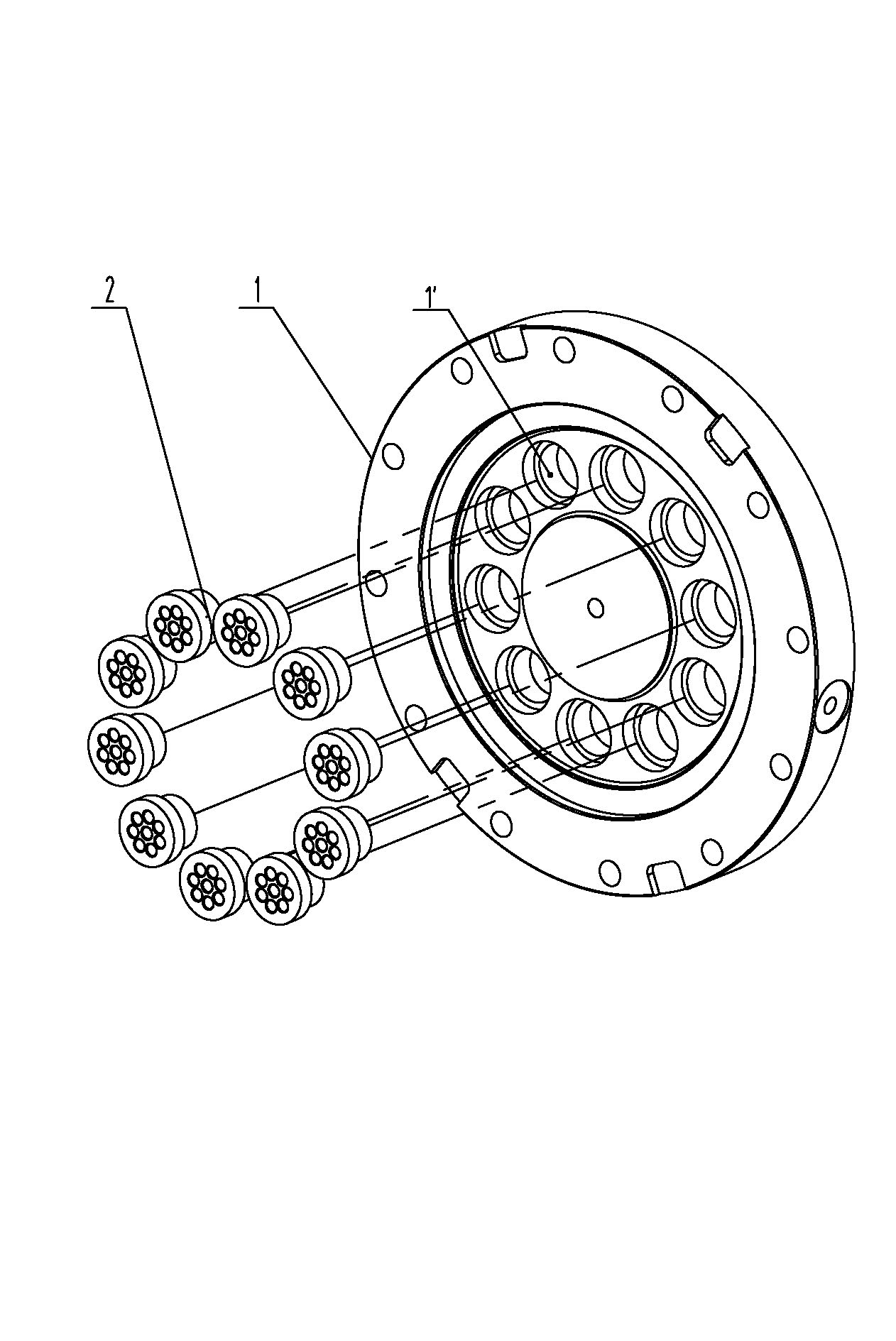

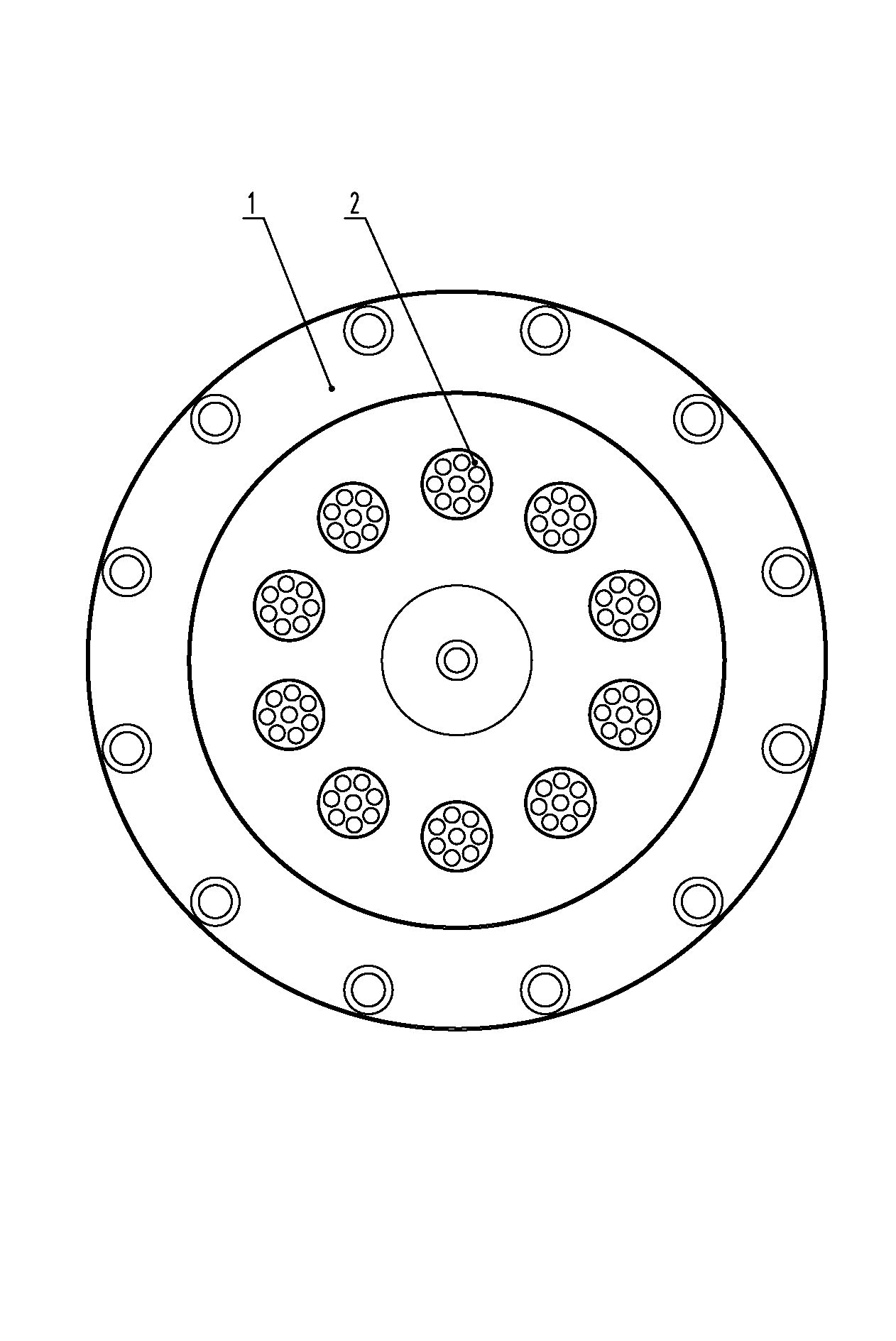

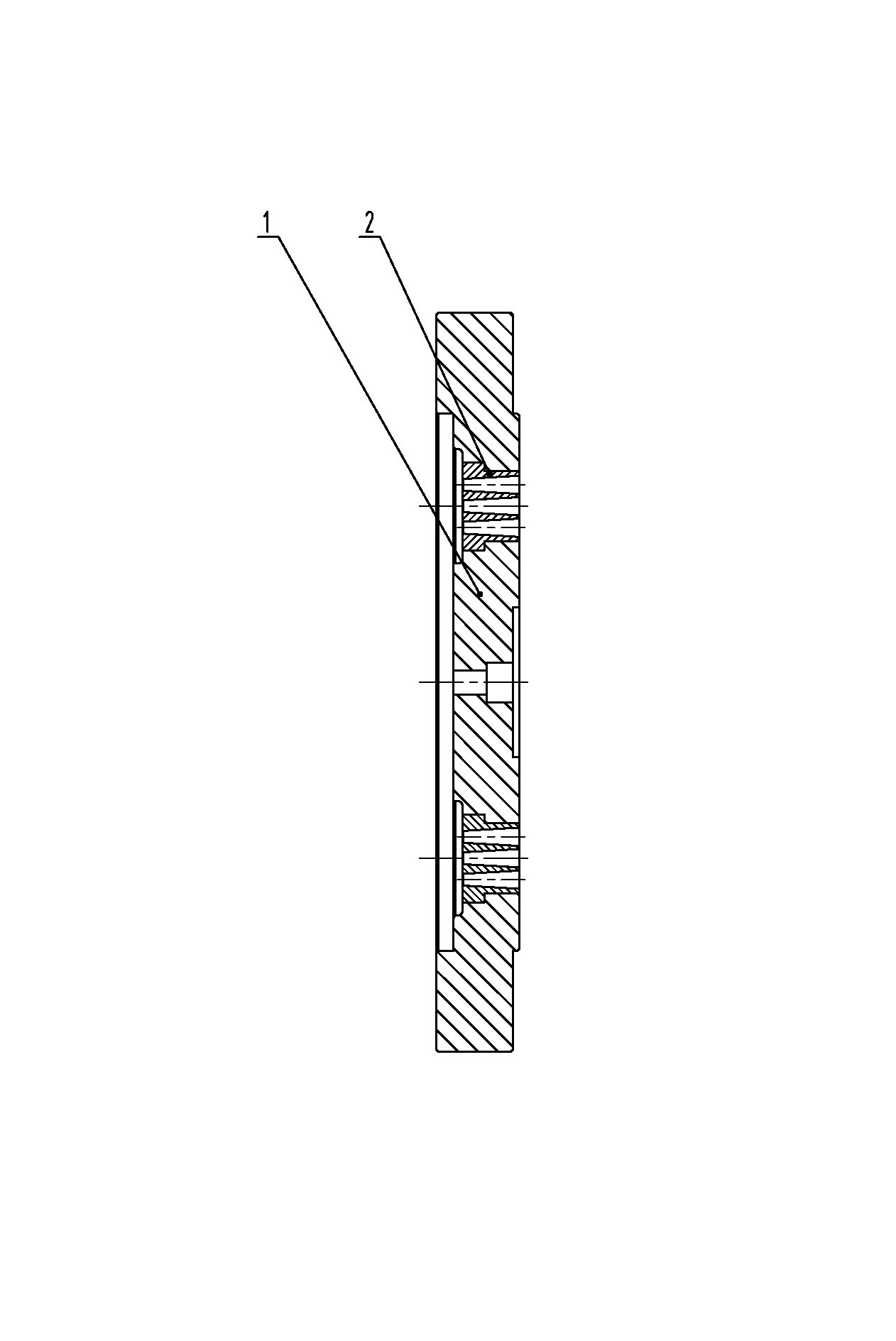

[0014] Such as figure 1 Shown in -4 is the discharge formwork of the extruder of the present invention, comprising a mold base 1 and a die head 2, the mold base 1 is evenly provided with some through holes 1' for installing the fixed die head 2, and the die head 2 is evenly provided with Several die holes 2', the die base 1 is made of metal material, and the die head 2 is made of plastic material. In this embodiment, PEEKCA30 with high hydrolysis resistance and high temperature resistance is selected as the material of the die head 2, which can ensure that the die head 2 is continuously extruded. Dimensional stability and a certain service life in the compression expansion process, such as Figure 4 Shown is the structural diagram of the die head, the length-to-diameter ratio L / D of the die hole 2' is 3 to 10, and the length-to-diameter ratio is specifically selected as 5 in this embodiment, and the die hole 2' is uniform from the feed end to the discharge end. The enlarged t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com