A dual-out automatic intermittent cutting device for biomass fuel particles

A technology of biomass fuel and cutting device, which is applied in the direction of biofuel, waste fuel, raw material extrusion and granulation, etc., can solve the problems of inconvenient maintenance, inconvenience of automatic processing, and increased cost of electronic structure, etc., and achieve high processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

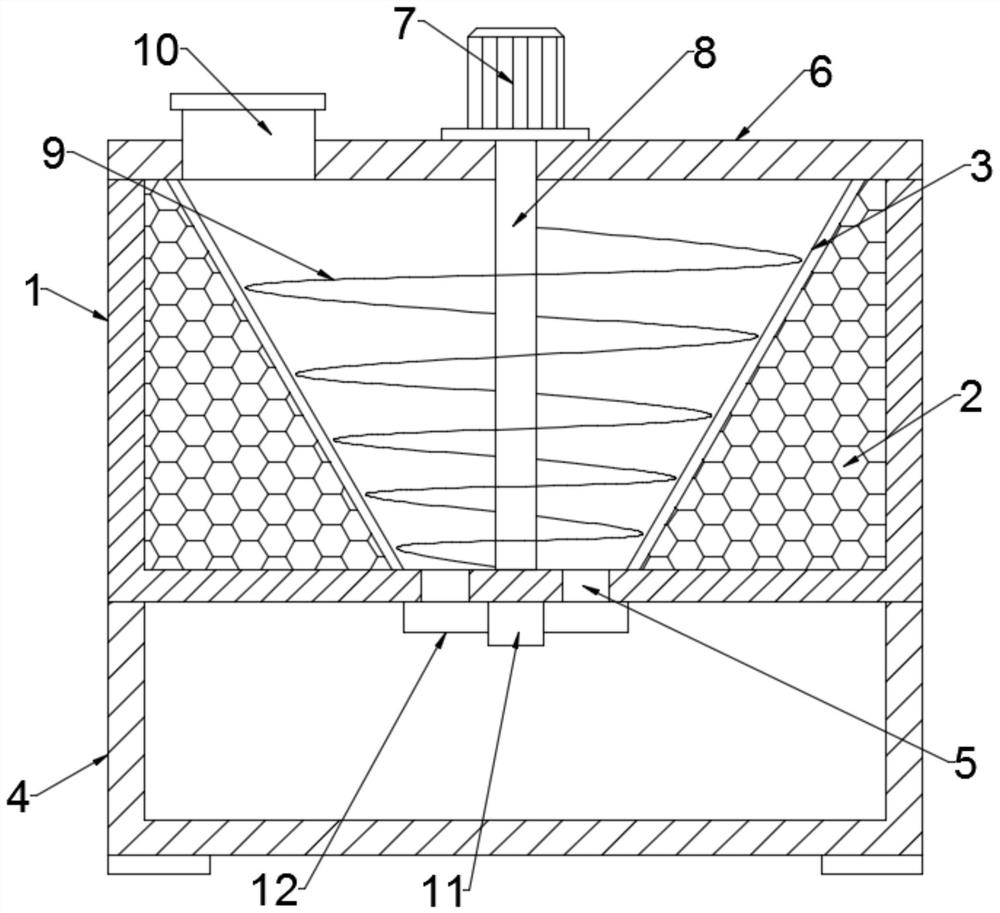

[0024] see figure 1 , in an embodiment of the present invention, a double-out automatic intermittent cutting device for biomass fuel particles, including a processing shell 1 and a collecting base 4, the collecting base 4 is located under the processing shell 1, and the inside of the processing shell 1 A heating conveying chamber 3 is connected, and a spirally wound heating resistance wire is attached to the surface of the heating conveying chamber 3. The lower end of the processing shell 1 is located below the heating conveying chamber 3, and two sets of symmetrical discharge holes are provided through it. 5. The upper end of the processing shell 1 is connected with an upper cover 6, the upper cover 6 is connected with a conveying mechanism, and the lower end of the processing shell 1 is also connected with a drive for radial reciprocating movement driven by the conveying mechanism The mechanism 11 and the material cutting mechanism 12 located below the discharge hole 5 and d...

Embodiment 2

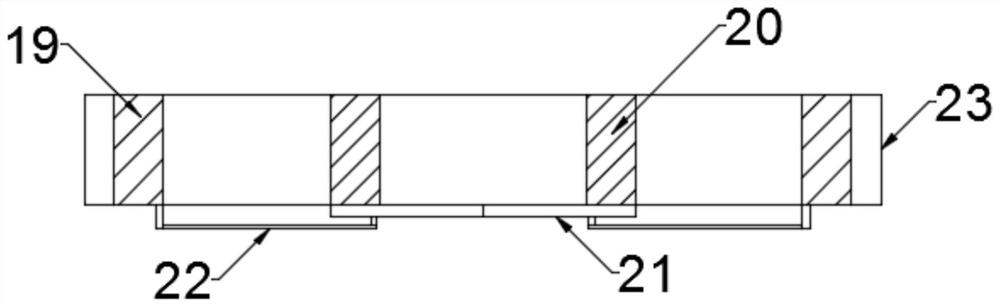

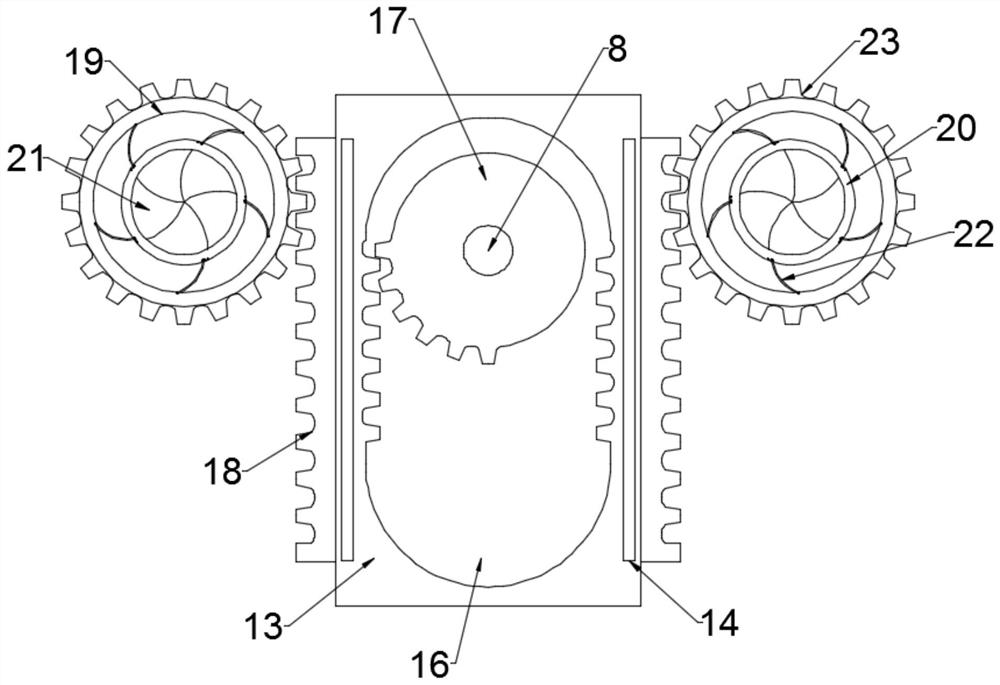

[0030] see Figure 2-4, in the embodiment of the present invention, a double-out automatic intermittent cutting device for biomass fuel particles. The driving gear 17 arranged on the periphery of the lower end of the rotating shaft 8 and the movable plate 13 meshed with the driving gear 17, the upper end of the movable plate 13 is slidingly connected with the lower end of the processing housing 1 through a sliding fit assembly, and the sliding fit assembly includes welding and fixing The sliding bar 14 on both sides of the upper end of the movable plate 13 and the sliding card 15 slidingly sleeved on the upper end of the sliding bar 14 are formed. The sliding bar 14 is a metal strip with a "T" shape in cross section. Assembled and fixed on the lower end of the processing shell 1 by welding.

[0031] The driving gear 17 is an incomplete gear, and the central angle corresponding to the tooth part of the driving gear 17 is 90°. The middle part of the movable plate 13 is provided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com