Numerical control woodworking machine tool and method for finely processing wood product thereby

A CNC woodworking machine tool and fine processing technology, which is applied in the direction of woodworking lathes, wood processing equipment, manufacturing tools, etc., can solve the problems of overlapping processing tracks of wood products, achieve the effects of overcoming the double eyelid phenomenon, improving processing efficiency, and solving technical problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

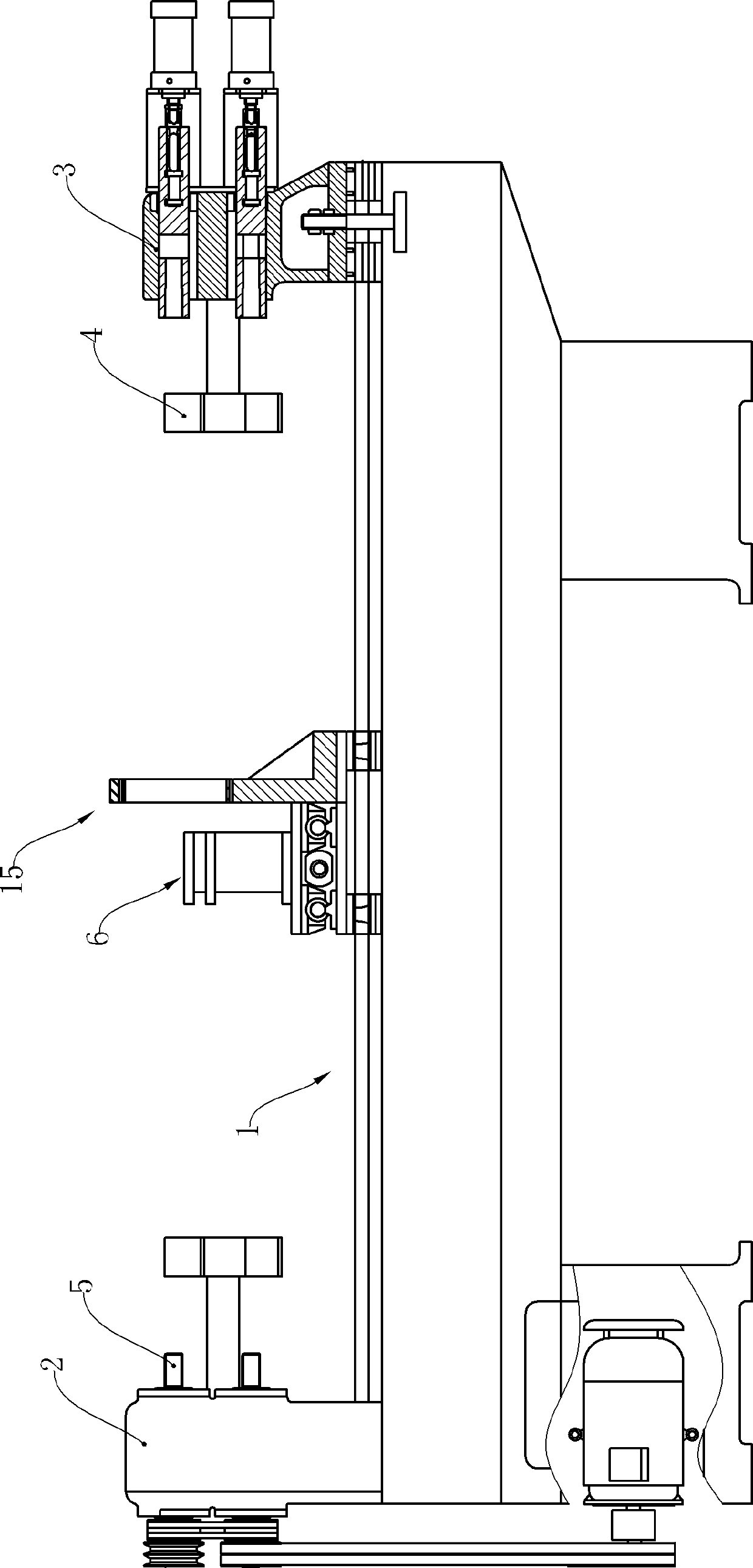

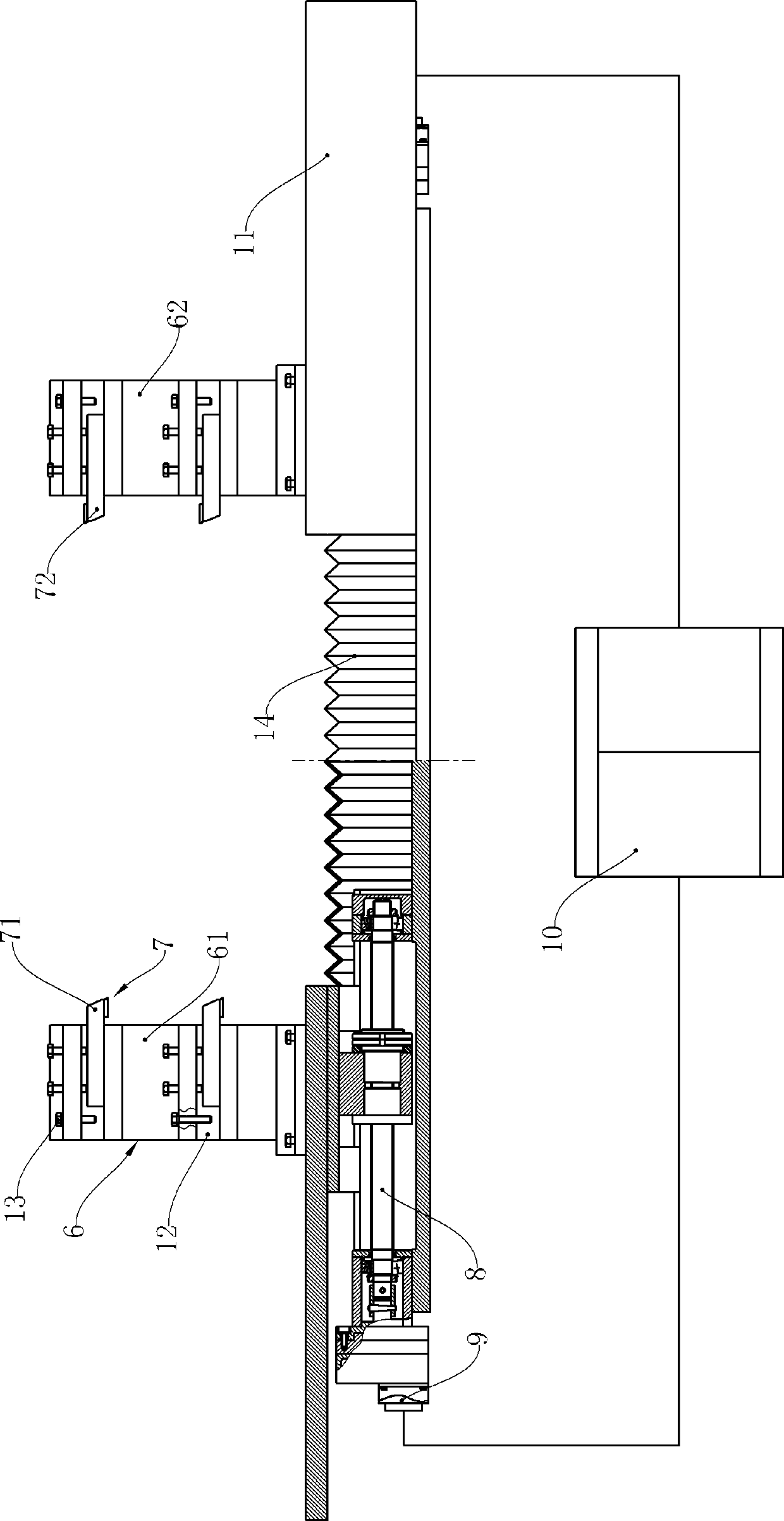

[0046] A method for finely processing woodwork using a numerically controlled woodworking machine tool to overcome double eyelids, using the following steps:

[0047] S1. Use the loading unit 4 to load the material, the workpiece is automatically located at the center of both ends and clamped on the rotating shaft 5; in this step, the loading unit 4 uses the application number 200920352567. The feeding device provided in the "lathe";

[0048] S2. Pre-turn the workpiece into a cylinder, measure and obtain the diameter and length of the cylinder;

[0049] S3. input the diameter and the length obtained in step S2 into the control module 10, confirm and save;

[0050] S4. set the processing speed by the control module 10 to be 10mm / min, and the roughing allowance is 10mm, confirm and save;

[0051] S5. Utilize the control module 10 to set the program of the machining trajectory scheme, and run; during operation, the rough turning tool 71 will rough the wood product, and then the...

Embodiment 2

[0054] A method for finely processing woodwork using a numerically controlled woodworking machine tool to overcome double eyelids, the steps are as follows:

[0055] S1. Using the loading unit 4 to load the material, the workpiece is automatically located at the center of both ends and clamped on the rotating shaft 5. In this step, the loading unit 4 uses the application number 200920352567.X, and the patent name is "Numerical Control Woodworking The feeding device provided in the "lathe";

[0056] S2. Pre-turn the workpiece into a cylinder, measure and obtain the diameter and length of the cylinder;

[0057] S3. Input the diameter and length obtained in step S2 into the control module, confirm and save;

[0058] S4. set the processing speed by the control module 10 to be 3000mm / min, and the roughing allowance is 50mm, confirm and save;

[0059] S5. Utilize the control module 10 to set the program of the machining trajectory scheme and run it.

[0060] The processed wood pr...

Embodiment 3

[0062] A method for finely processing woodwork using a numerically controlled woodworking machine tool to overcome double eyelids, the steps are as follows:

[0063] S1. Use the loading unit 4 to load the material, and the workpiece will automatically find the center of both ends and clamp it on the rotating shaft. In this step, the loading unit 4 uses the application number 200920352567.X, and the patent name is "Numerical Control Woodworking Lathe The feeding device provided in ";

[0064] S2. Pre-turn the workpiece into a cylinder, measure and obtain the diameter and length of the cylinder;

[0065] S3. input the diameter and the length obtained in step S2 into the control module 10, confirm and save;

[0066] S4. set the speed of processing by the control module 10 to be 1500mm / min, and the roughing allowance is 0mm, confirm and save;

[0067] S5. Utilize the control module 10 to set the program of the machining trajectory scheme, run; the interpolation operation unit in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com