Printing member conveying device of curved-surface printer

A technology for curved surface printing machines and substrates, which is applied to printing machines, rotary printing machines, printing, etc., and can solve the problems of automatic feeding and stacking of short cups and bowls whose height is smaller than the diameter, poor installation accuracy of feeding screws, The problem of high failure rate of material distribution and feeding can achieve the effect of fast and accurate synchronous diameter adjustment, convenient high-speed feeding, and high installation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

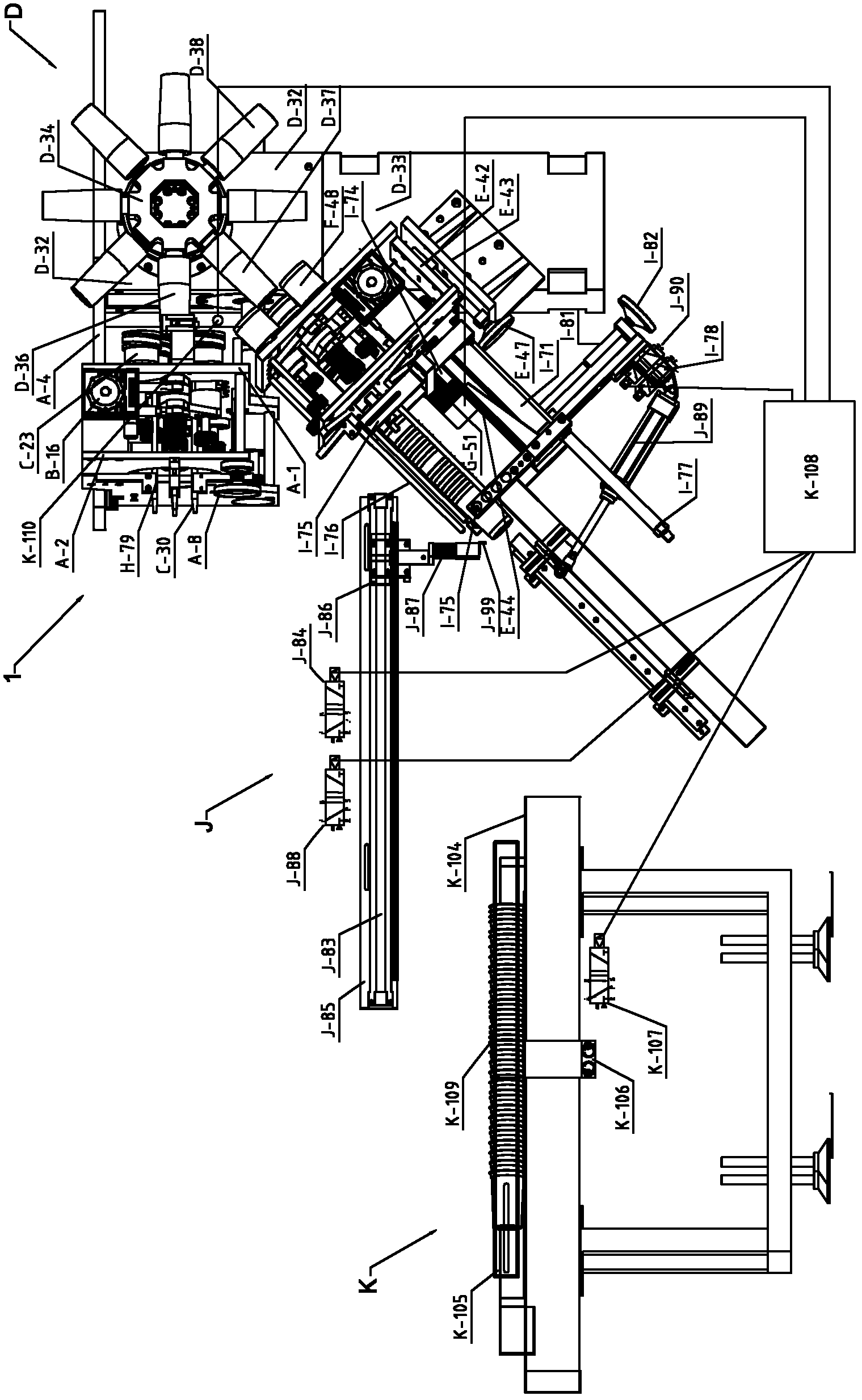

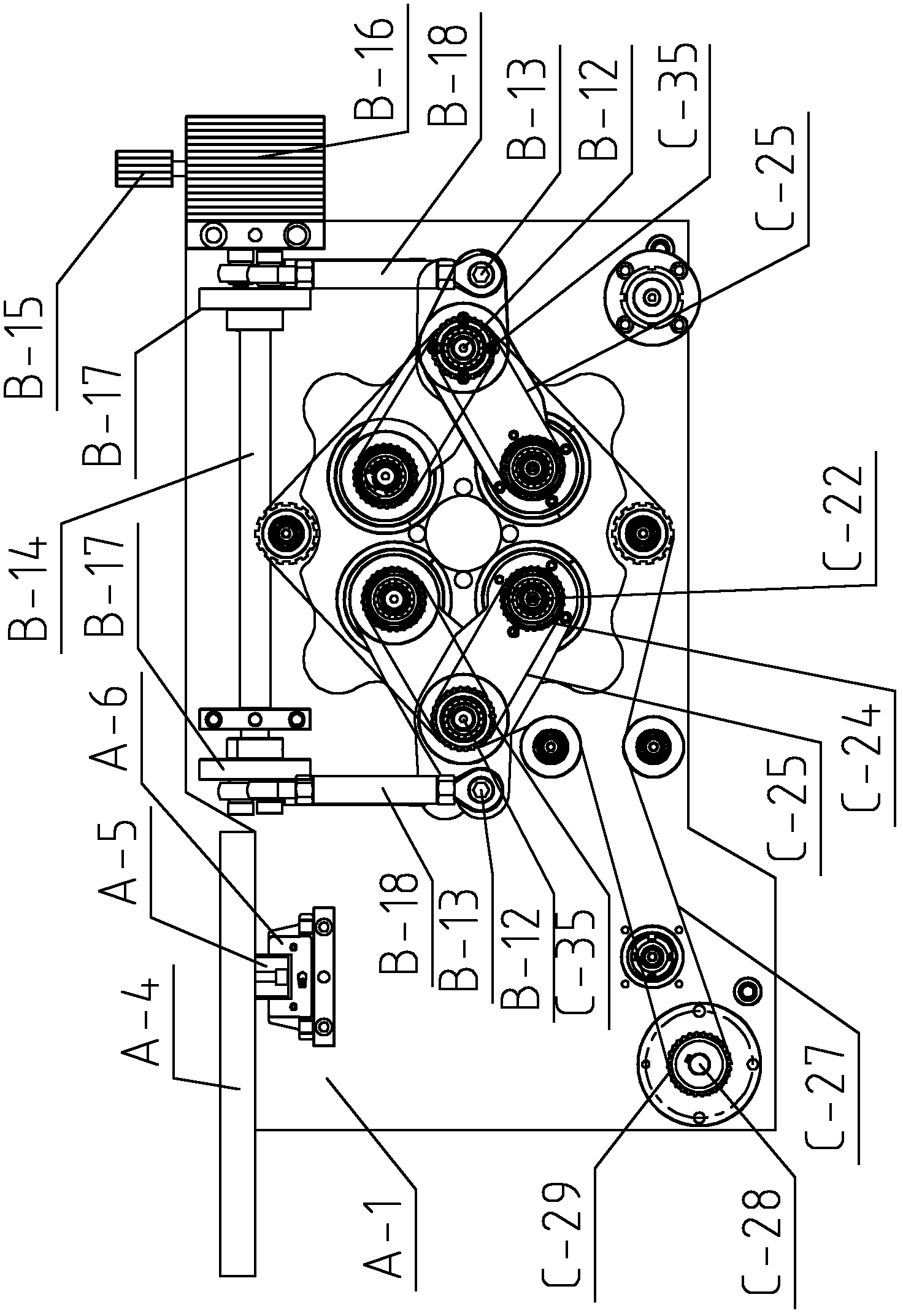

[0032] refer to figure 1 and figure 2 , the first embodiment of the present invention is a feeding device 1, comprising three parts of a feeding support frame A, a screw head movement adjustment mechanism B, and a screw head rotation transmission mechanism C, and the detailed configuration is as follows:

[0033] The feeding support frame A includes a comprehensive support frame A-4, a support frame front plate A-1, a support frame rear plate A-2, a support frame side plate A-3, a support frame top plate A-102, and a screw rod A for moving in and out. -7. Adjust the forward and backward hand wheel A-8, adjust the forward and backward track A-5 and slide block A-6, the support frame side plate A-3 and the support frame top plate A-102 are connected to the fixed support frame front plate A-1 and the support Frame rear plate A-2; wherein, the comprehensive support frame A-4 is installed and fixed on the top of the step indexer D-32 and extends to both sides of the step indexer ...

Embodiment 2

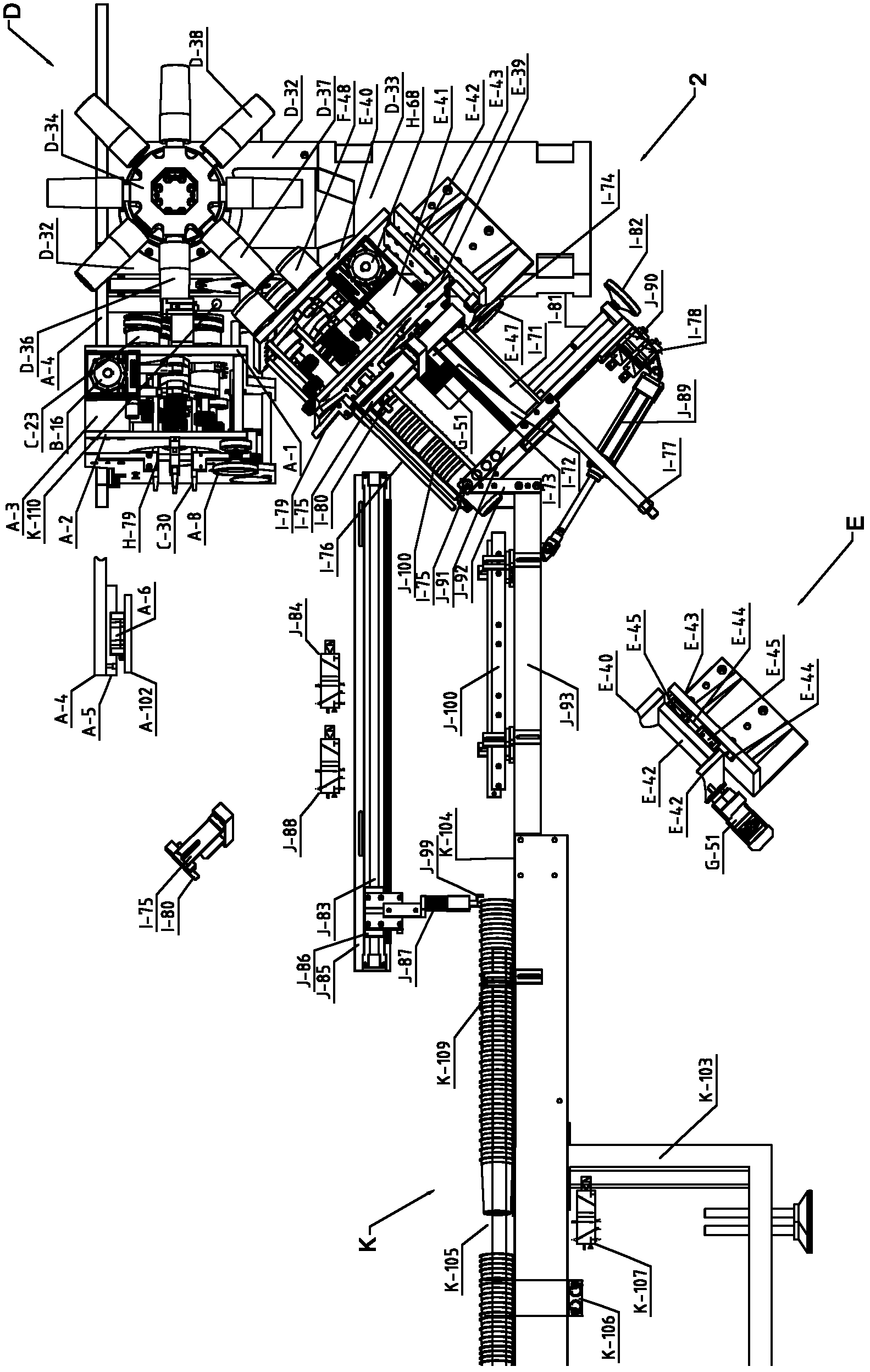

[0040] refer to figure 1 and figure 2 , the second embodiment of the present invention is a material receiving device 2, including a material receiving support frame E, a material receiving and pressing cam transmission device G, a material receiving and pressing cam moving mechanism H, and a material receiving and pressing cam F four parts, The detailed configuration is as follows:

[0041] The material receiving support frame E includes a material receiving device fixing seat E-43, a support frame front plate E-40, a support frame rear plate E-39, a support frame bottom plate E-42, a support frame side plate E-41, and a slider E-45, rail E-44, screw mandrel E-46 and handwheel E-47; wherein, the fixed seat E-43 of the material receiving device is fixed on the support seat D-33 of the step indexer obliquely with the horizontal plane, so that four The central axis of a material receiving and pressing cam F and the central axis of the support frame front plate E-40 and the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com