Movable automatic gas station

A gas station, mobile technology, applied in the field of mobile automatic gas stations, can solve the problems of high labor intensity, pollute the environment, reduce the service life of equipment, etc., and achieve the effect of reducing physical labor intensity, high degree of automation, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

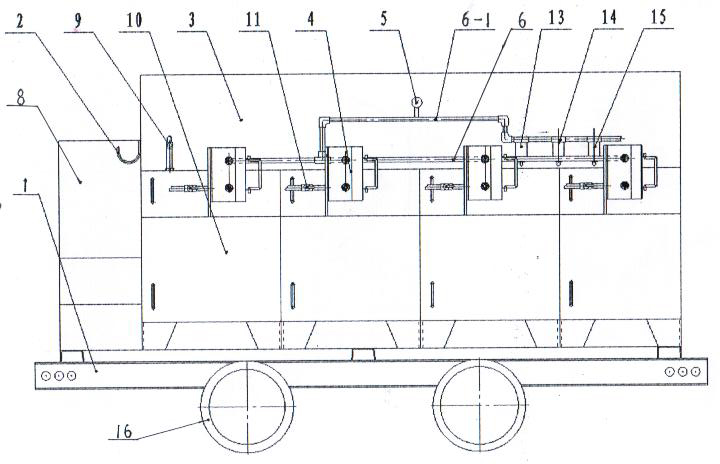

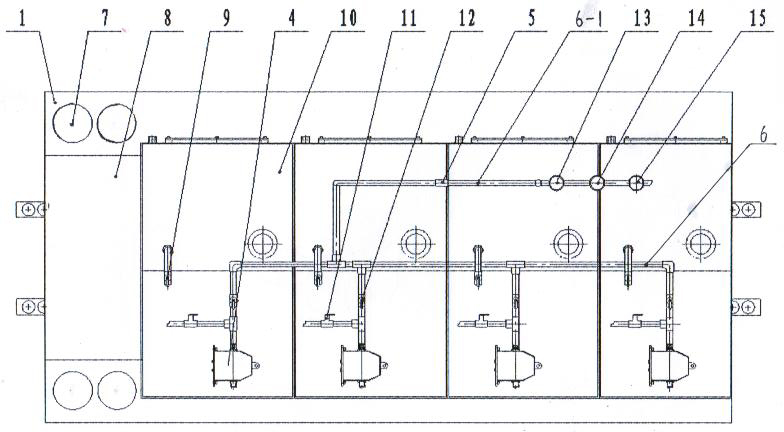

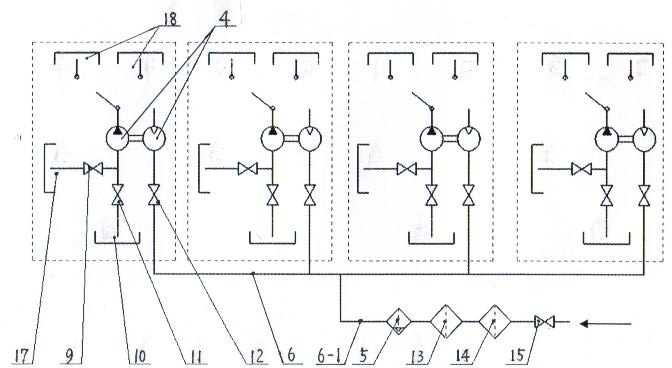

[0011] Examples, see attached figure 1 , 2 , four road wheels 16 are adorned below the mining vehicle body 1 of the mobile automatic gas station, and a warehouse 3 is fixedly installed on the mining vehicle body 1. In the warehouse 3, four independent oil tanks 10 are arranged side by side, and different greases are respectively installed in the four oil tanks 10 . The top of each oil tank 10 is provided with a pump-motor integrated oil supply device 4, and each pump-motor integrated oil supply device 4 communicates with the ball valve one 9, the ball valve two 11 and the ball valve three 12 with the connecting pipe 6. A branch connecting pipe 6 is connected with a tee on the main connecting pipe 6-1, and a lubricator 5, a secondary filter 13, a main line filter 14 and Main line ball valve 15. Be provided with hook 2 on the left side of warehouse 3, can hang various tools. A sandbox 8 is established above the mine car body 1 on the left side of the warehouse 3, and sand fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com