Multi-walled carbon nanotube / AgBiS2 semiconductor nanoparticle hybrid material and preparation method thereof

A technology of multi-walled carbon nanotubes and nanoparticles, which is applied in the field of multi-walled carbon nanotubes/AgBiS2 semiconductor nanoparticle hybrid materials and their preparation, can solve the problems of increased surface defects of carbon nanotubes, complicated experimental steps, and the like, and achieves good results. The effect of optical limiting performance, easy availability of raw materials, and excellent optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

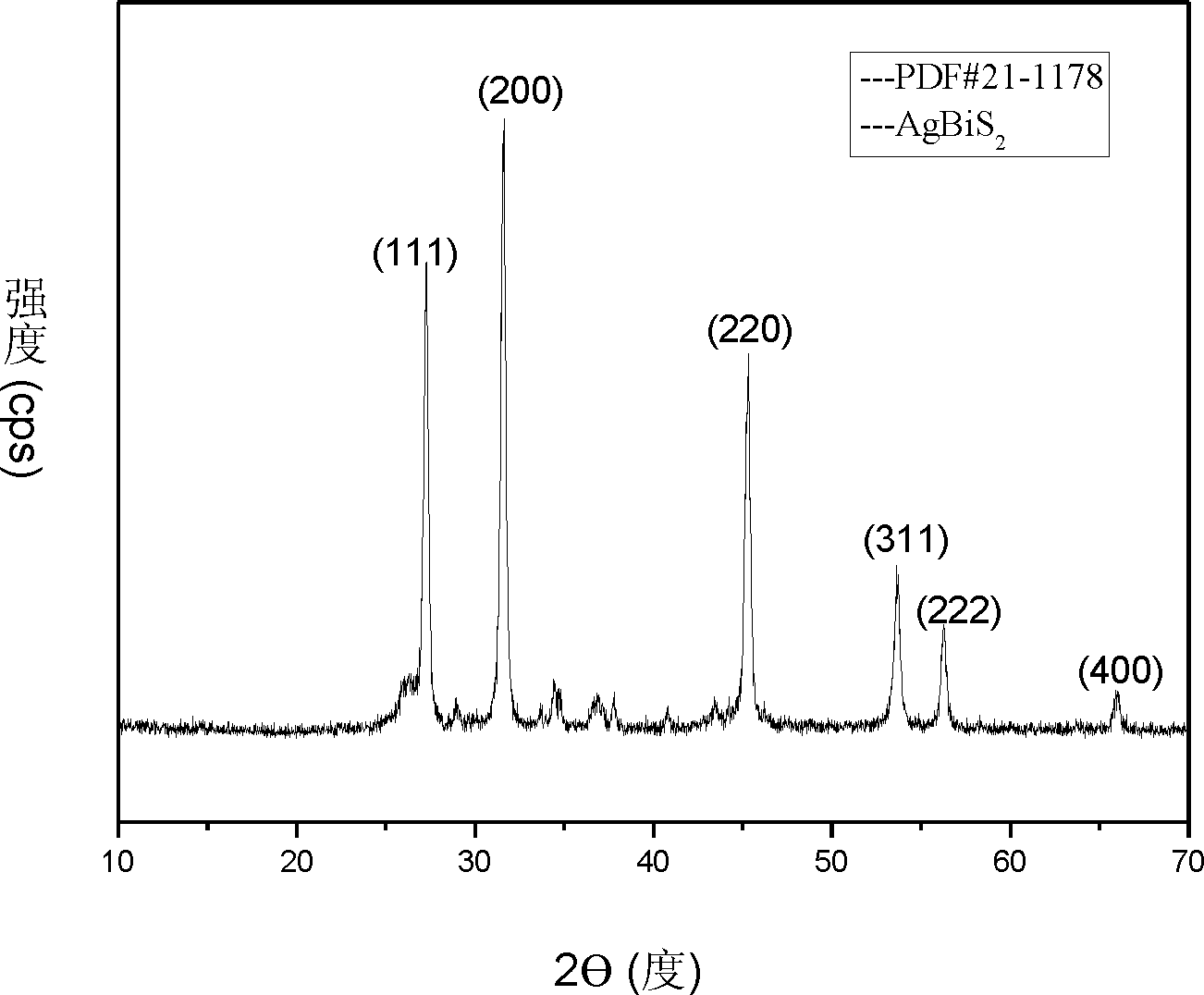

Embodiment 1

[0032] (1) Weigh 30 mg of multi-walled carbon nanotubes in 30 mL of a mixed solution of diethylene glycol and glycerol, the solvent volume ratio is 1:1, and ultrasonically disperse at room temperature for 2 h;

[0033] (2) Weigh 0.3mmolAgNO respectively 3 and 0.3mmolBi(NO 3 ) 3 ·5H 2 O, add 30mL of diethylene glycol and glycerin mixed solution with a solvent volume ratio of 1:1, and ultrasonically dissolve it for 20min;

[0034] (3) Weigh 0.6 mmol of thiosemicarbazide and dissolve it in 30 mL of a mixed solution of diethylene glycol and glycerol with a solvent volume ratio of 1:1, and dissolve it by ultrasonication for 20 minutes;

[0035] (4) Add the solution in (2) dropwise to (1), stir magnetically at room temperature for 1 h, then continue to add the solution in (3) dropwise to (1), and continue stirring for 1 h to make it evenly dispersed;

[0036] (5) Transfer the solution obtained in step (4) to a hydrothermal reaction kettle, seal it, and react at 200° C. for 6 hou...

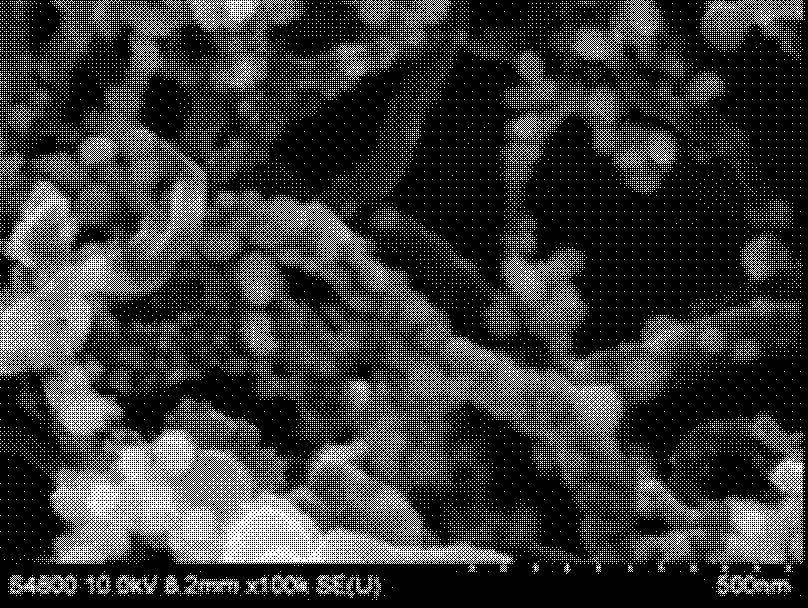

Embodiment 2

[0041] (1) Weigh 30 mg of multi-walled carbon nanotubes in 30 mL of a mixed solution of diethylene glycol and glycerol, the solvent volume ratio is 1:1, and ultrasonically disperse at room temperature for 2.5 h;

[0042] (2) Weigh 0.3mmolAgNO respectively 3 and 0.3mmolBi(NO 3 ) 3 ·5H 2O, add 30mL of diethylene glycol and glycerin mixed solution with a solvent volume ratio of 1:1, and ultrasonically dissolve it for 20min;

[0043] (3) Weigh 0.6 mmol of thiosemicarbazide and dissolve it in 30 mL of a mixed solution of diethylene glycol and glycerol with a solvent volume ratio of 1:1, and dissolve it by ultrasonication for 20 minutes;

[0044] (4) Add the solution in (2) dropwise to (1), stir magnetically at room temperature for 1 h, then continue to add the solution in (3) dropwise to (1), and continue stirring for 1 h to make it evenly dispersed;

[0045] (5) Transfer the solution obtained in step (4) to a hydrothermal reaction kettle, seal it, and react at 200° C. for 3 ho...

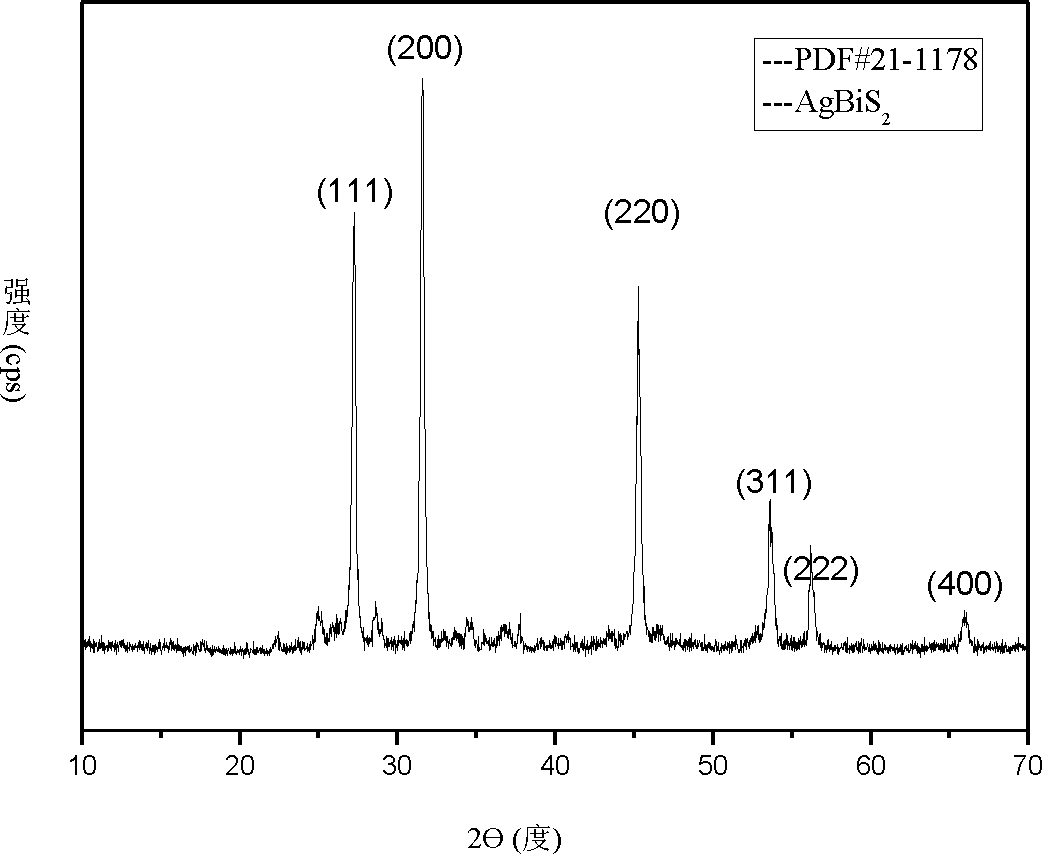

Embodiment 3

[0050] (1) Weigh 30 mg of multi-walled carbon nanotubes in a mixed solution of 30 mL of ethylene glycol and glycerol, the solvent volume ratio is 1:1, and ultrasonically disperse at room temperature for 2 h;

[0051] (2) Weigh 0.3mmolAgNO respectively 3 and 0.3mmolBi(NO 3 ) 3 ·5H 2 O, add 30mL of the mixed solution of ethylene glycol and glycerol with a solvent volume ratio of 1:1, and ultrasonically dissolve it for 20min;

[0052] (3) Weigh 0.6 mmol of thiosemicarbazide and dissolve it in 30 mL of a mixed solution of ethylene glycol and glycerol with a solvent volume ratio of 1:1, and dissolve it by ultrasonication for 20 min;

[0053] (4) Add the solution in (2) dropwise to (1), stir magnetically at room temperature for 1 h, then continue to add the solution in (3) dropwise to (1), and continue stirring for 1 h to make it evenly dispersed;

[0054] (5) Transfer the solution obtained in step (4) to a hydrothermal reaction kettle, seal it, and react at 200° C. for 6 hours;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com