Non-stop ash discharge device for fixed bed clearance gas producer

A coal gasifier, interstitial technology, applied in the field of non-stop ash discharge device for fixed-bed interstitial gasifiers, can solve the problem that the continuous operation of the gasifier cannot be guaranteed, the effective gas production time can be reduced, and there is a waiting time for the furnace To achieve the effect of improving the utilization rate of raw materials, easy operation and maintenance, and improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

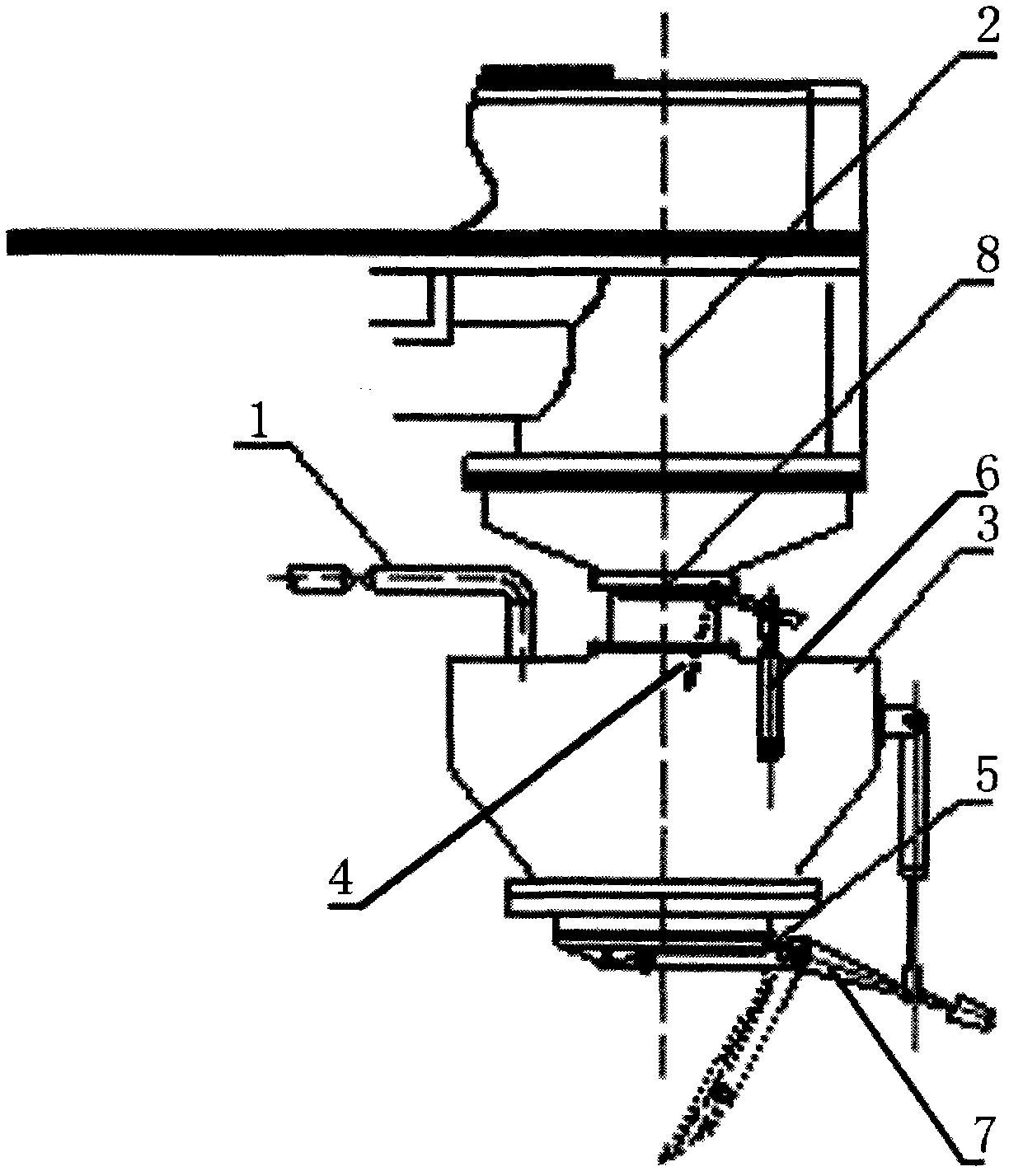

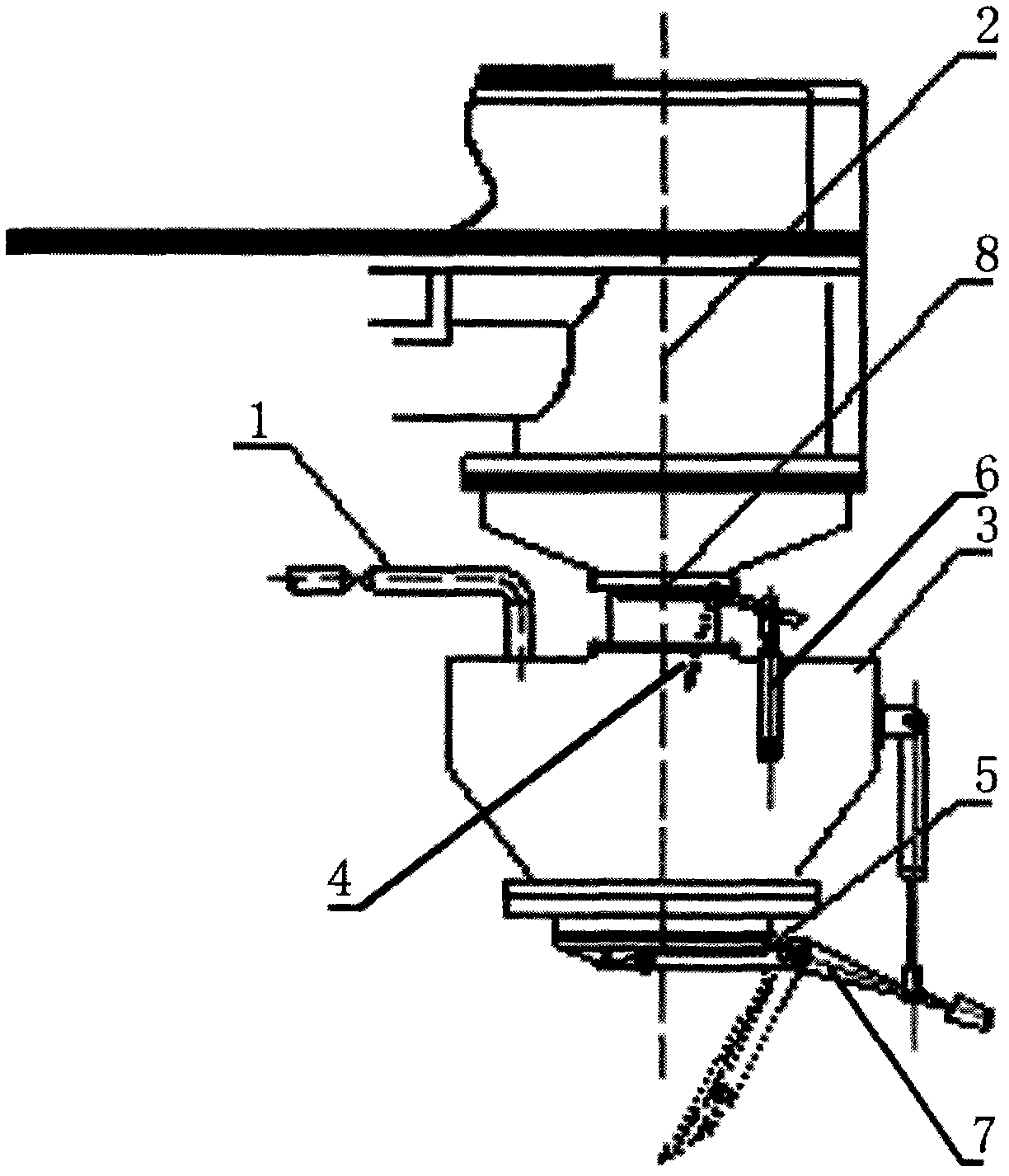

[0024] Such as figure 1 The shown device includes steam replacement pipe 1, upper ash box part, lower ash box part and ash door control device. The upper ash box part includes upper ash box body 2, upper ash door sealing assembly into 4; the upper ash door sealing assembly 4 is installed on the lower part of the upper ash box body 2;

[0025] The lower ash box part includes the lower ash box body 3 and the lower ash door sealing assembly 5; the lower ash door sealing assembly 5 is installed at the lower part of the lower ash box body 3;

[0026] The upper ash door sealing assembly 4 is connected to the lower ash box body 3;

[0027] The upper ash door sealing assembly 4 and the lower ash door sealing assembly 5 are respectively connected to the ash door control device; the ash door control device intermittently controls to open the upper The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com