Conductive laminated body and touch panel using the same

A technology of conductive laminates and protective layers, applied in the field of conductive laminates, can solve the problems of slow processing speed, unsuitable for large-area processing, high cost, etc., and achieve good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

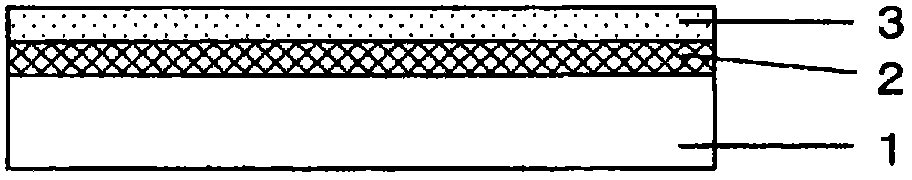

[0256] A polyethylene terephthalate film having a thickness of 125 μm, Lumiror (registered trademark) U46 (manufactured by Toray Corporation) was used as a base material, and “conductive layer A” was laminated on one surface of the base material.

[0257]Next, 296 g of "protective layer material A" and 704 g of "ethyl acetate" were mixed and stirred to prepare a protective layer coating liquid. Using a slot die coater equipped with a spacer made of sus (spacer thickness: 50 μm), apply this protective layer coating liquid on the above-mentioned “conductive layer A”, dry at 120° C. for 2 minutes, and set A protective layer having a thickness of 950 nm was used to obtain the conductive laminate of the present invention.

Embodiment 2

[0259] The composition of the protective layer coating solution was 500 g of "protective layer material A" and 1,500 g of "ethyl acetate". It was produced in the same manner as in Example 1, and a protective layer with a thickness of 800 nm was provided to obtain the conductive layer of the present invention. fit.

Embodiment 3

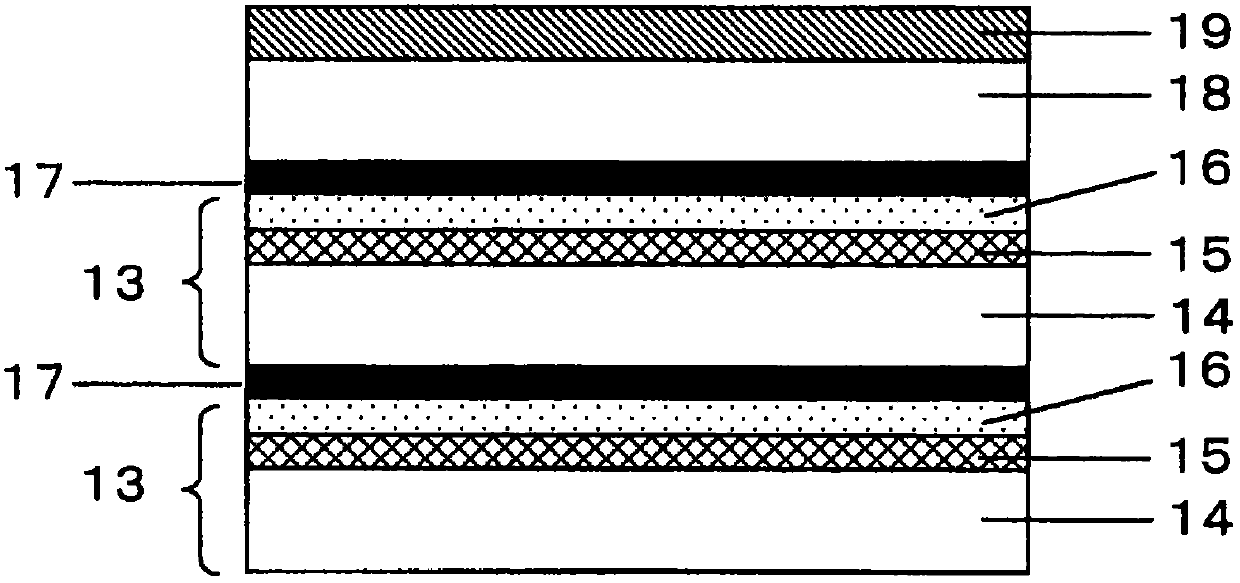

[0261] A polyethylene terephthalate film having a thickness of 125 μm, Lumiror (registered trademark) U46 (manufactured by Toray Corporation) was used as a base material, and “conductive layer B” was laminated on one surface of the base material.

[0262] Next, 150 g of "protective layer material B", 3.60 g of "additive A", 7.15 g of "additive B", and 1907 g of "ethyl acetate" were mixed and stirred to prepare a protective layer coating liquid. Using a slot die coater equipped with a spacer made of sus (spacer thickness: 50 μm), apply this protective layer coating solution on the above-mentioned "conductive layer B", and dry it at 120°C for 2 minutes. at 1.2J / cm 2 It cured by irradiating ultraviolet rays, provided a protective layer with a thickness of 450 nm, and obtained the conductive laminate of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com