Milling tool for gear milling

A milling tool and milling technology, applied in the direction of gear cutting tools, gear tooth manufacturing tools, milling cutters, etc., to achieve the effect of long service life and improved flexibility of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

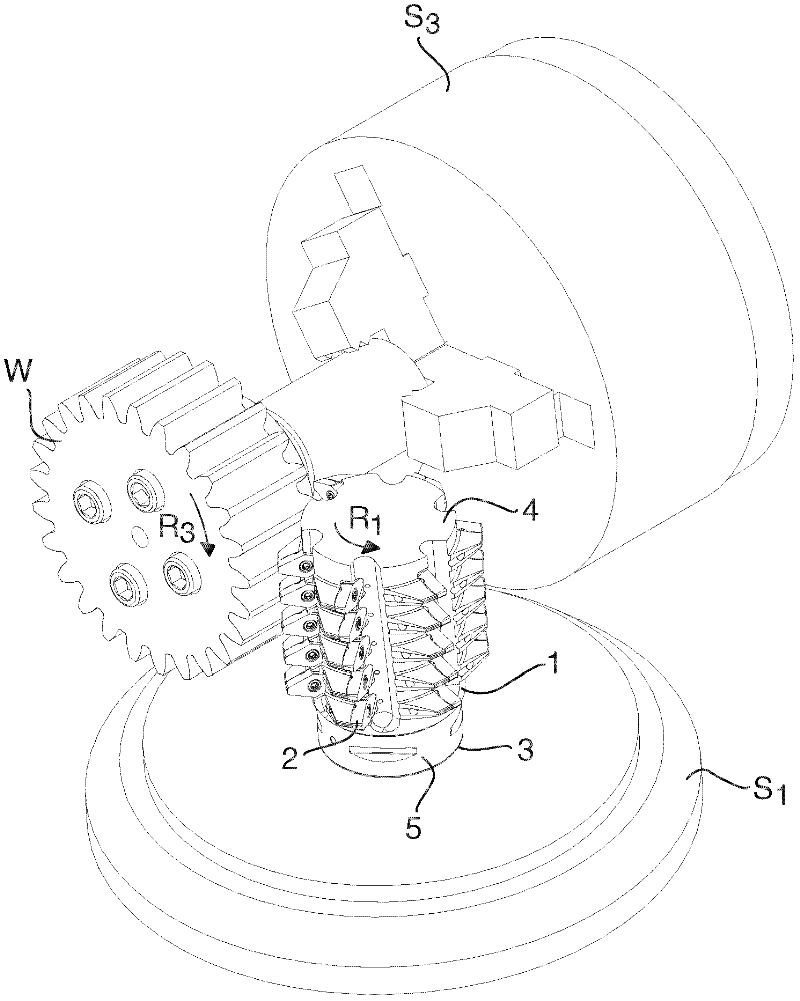

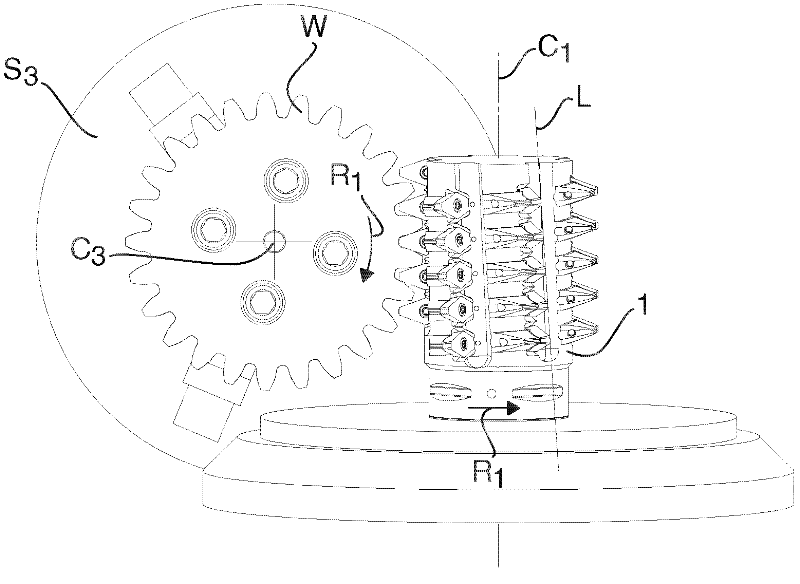

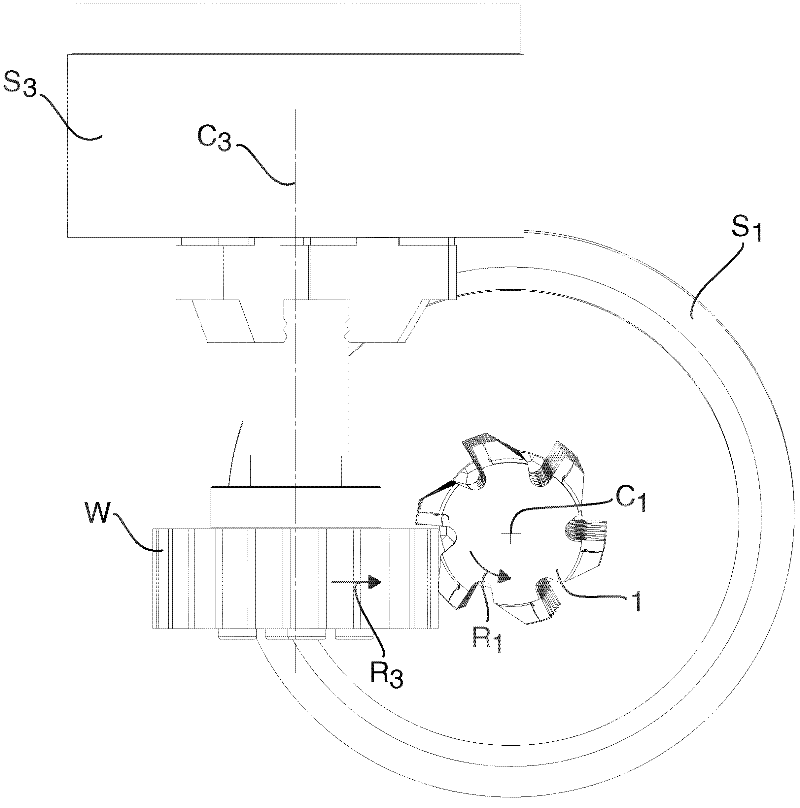

[0044] Figure 1-9 An embodiment of a milling tool formed for gear cutting and more particularly for so-called hobbing of toothed workpieces W is shown. Milling tools are suitable for cutting machining of different workpieces W such as gears, racks, splines, impellers for hydraulic pumps and similar cogged elements.

[0045] The milling tool comprises a tool body 1 and a large number of replaceable milling inserts 2 . The milling insert 2 is made of a material harder than the tool body 1 , such as cemented carbide. The tool body 1 can be manufactured from steel.

[0046] The tool body 1 defines an axis of rotation C 1 And has a fixed end 3 and an opposite outer end 4. Axis of rotation C 1 Extends through the fixed end 3 and the outer end 4 . On the fixed end 3 there is a fastening pin 5, see Figure 5 , for securing the tool body 1 and the milling tool to the tool spindle S of the milling cutter or multi-operation machine tool 1 middle. The tool body 1 revolves around...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com