Miniature table press of ball screw driven by AC servo direct drive motor

A technology of AC servo motors and desktop presses, which is applied to presses, stamping machines, manufacturing tools, etc., can solve problems such as poor controllability, low mold life, and large vibration and noise, so as to save electricity and lubricating oil, and promote Development and promotion of applications, the effect of reducing the cost of machine use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

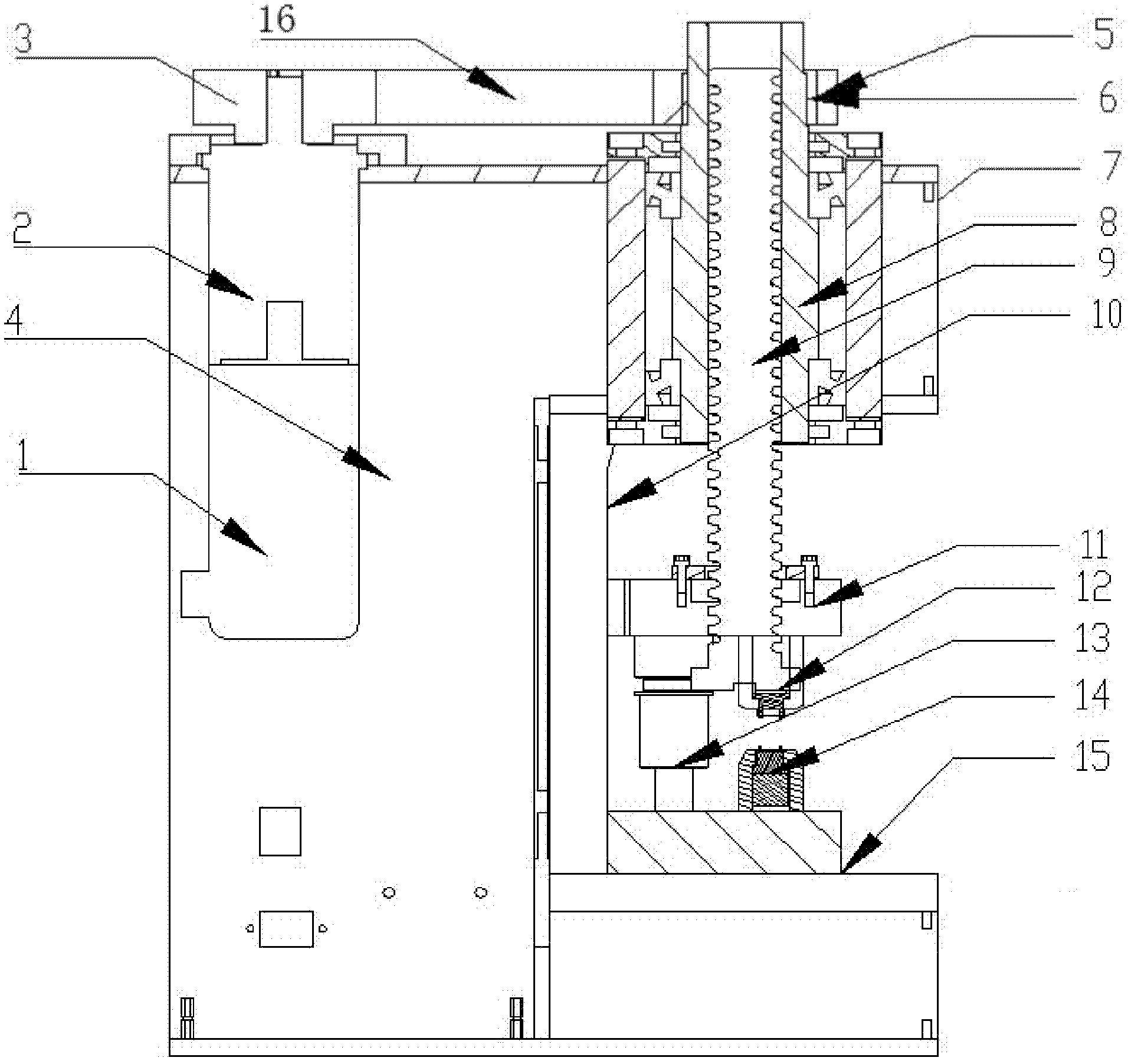

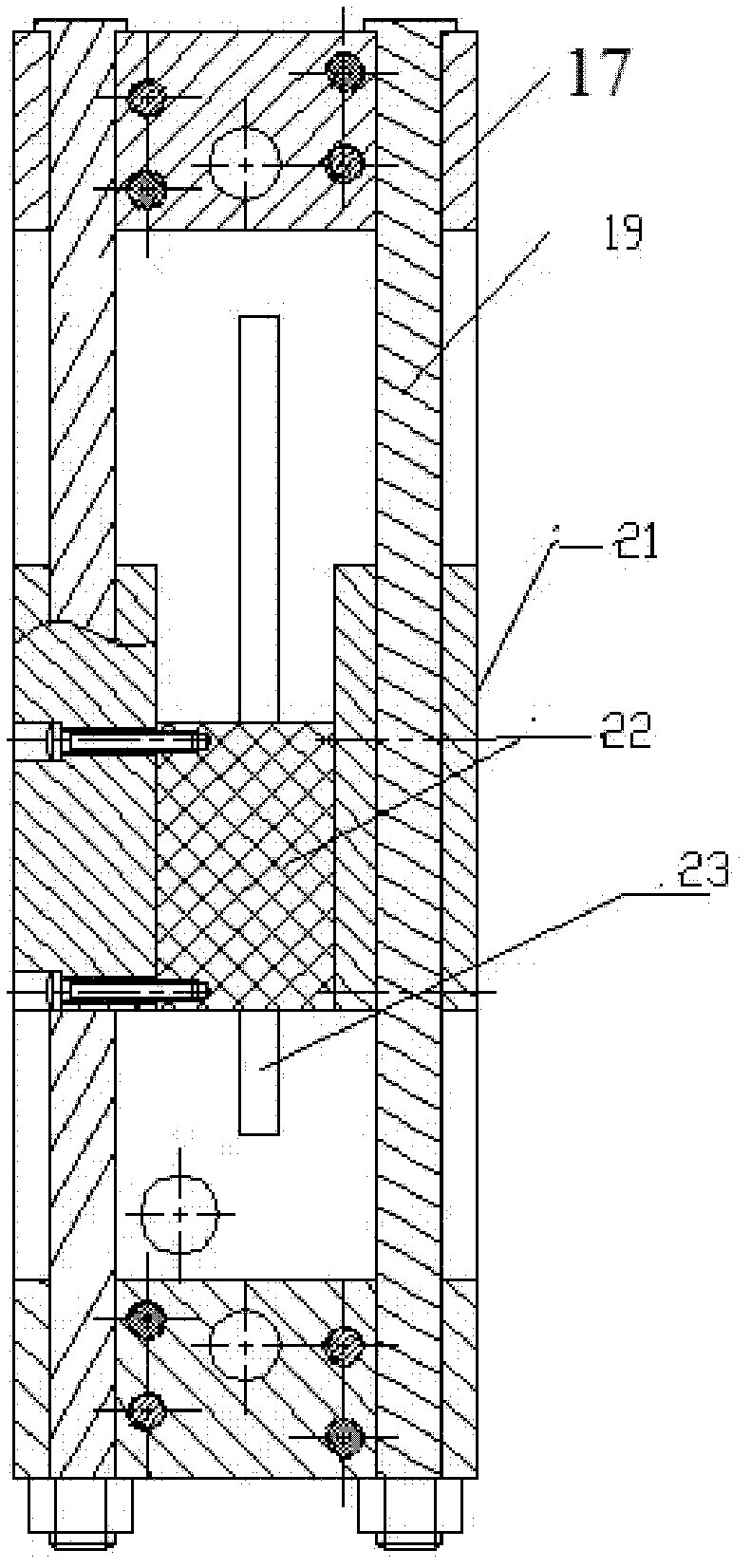

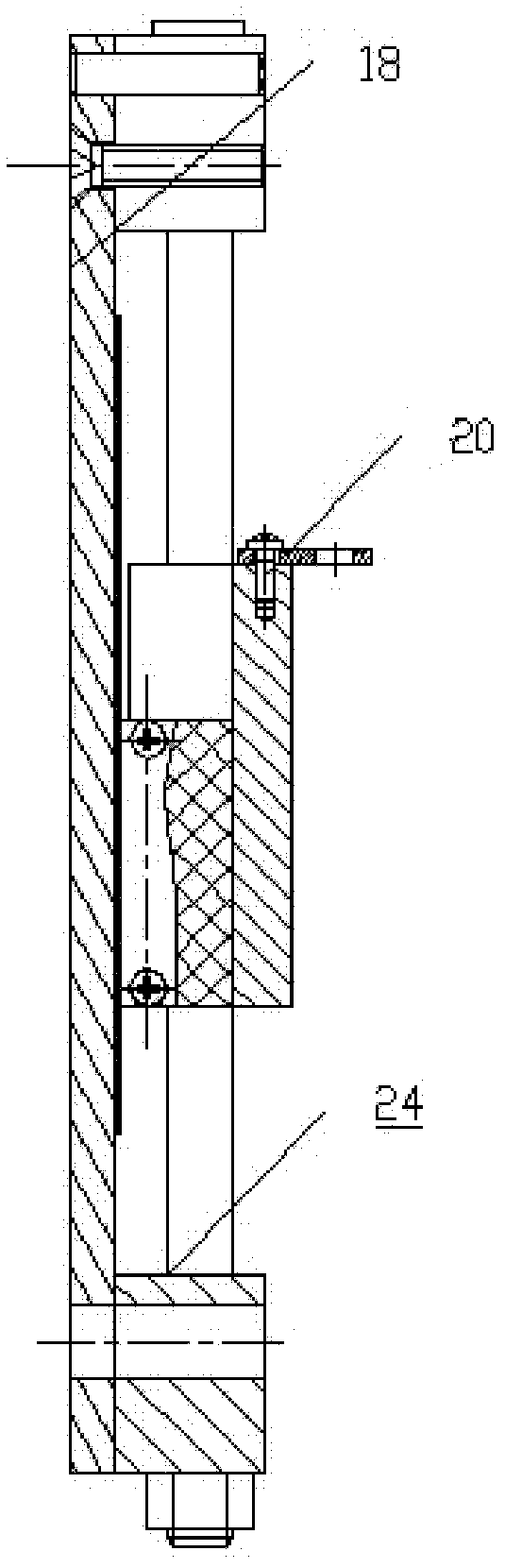

[0012] refer to figure 1 , a small desktop press with an AC servo direct drive motor driving a ball screw, including an AC servo motor 1 connected to the input end of the AC servo motor 1 and the planetary gear reducer 2, and the AC servo motor 1 and the planetary gear reducer 2 are fixed On the frame 4, the output end of the planetary gear reducer 2 is equipped with a driving wheel 3, the driving wheel 3 is connected with the driven wheel 5 through a belt 16, the driving wheel 3 and the driven wheel 5 are fixed on the frame 4, and the driven wheel 5 and the driven wheel 5 are fixed on the frame 4. The nut 6 is connected, the nut sleeve 8 is fixed on the frame 4, and its upper end is threaded to cooperate with the nut 6, the nut sleeve 8 is installed on the ball screw 9, the nut sleeve 8 rotates in situ, and drives the ball screw 9 performs rotational movement, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com