Method for treating bottom boiler water

A treatment method and bottom pot water technology, which is applied in the field of wine making, can solve problems such as bottom pot water pollution, achieve small investment, solve environmental pollution problems, and have obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

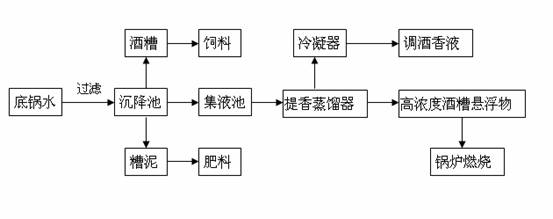

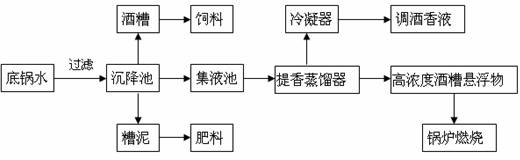

Method used

Image

Examples

Embodiment

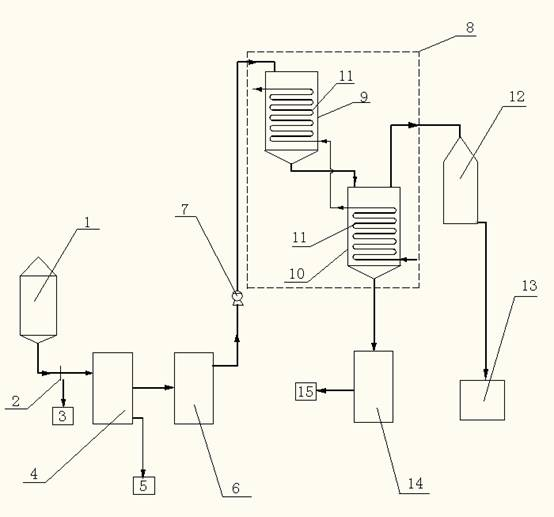

[0024] a) filter

[0025] The bottom pot water 500kg of distiller's 1 is filtered through 80 mesh filter screen 2, and filter residue is distiller's grains 3, gets 35kg after drying, sells as feed;

[0026] b) Settlement

[0027] Filtrate 450kg flows into settling tank 4, leaves standstill 12 hours, makes bad mud 5 sedimentation, and supernatant 400kg flows into sump tank 6 and settles again, and the bad mud 5 of settlement is 50kg and sells as fertilizer;

[0028] c) distillation

[0029] The supernatant of the liquid collection tank 6 is added by the pump 7 to the Titian still 8 formed in series by the stainless steel still A9 with the serpentine heating tube 11 inside and the stainless steel still B10 connected in series. The bottom of the stainless steel still A9 is higher than At the water inlet of stainless steel distiller B10, the steam with a temperature of about 110°C and a distillation pressure of 0.15Mpa passes through the serpentine heating tube 11 in the stainle...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap