Electrochemical polishing electrolytic solution of zirconium alloy and electrochemical polishing method of electrochemical polishing electrolytic solution

An electrochemical and zirconium alloy technology, applied in the electrochemical polishing electrolyte of zirconium alloy and the field of electrochemical polishing, can solve the problems of high risk, unfavorable environmental protection and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

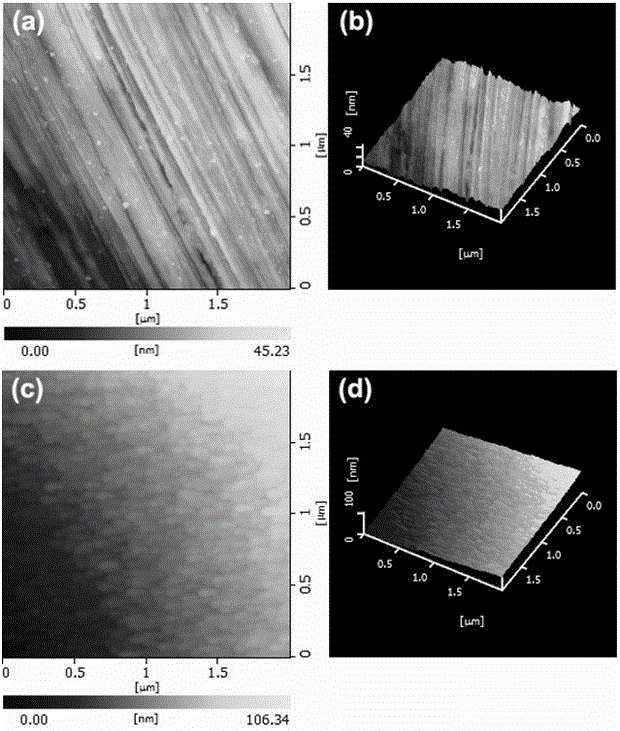

[0026] This example adopts this electrochemical polishing electrolyte and surface polishing technology, to Zr 64.13 Cu 15.75 Ni 10.12 Al 10 The (atomic ratio) alloy surface is polished to give it a specular luster and to obtain very little surface roughness.

[0027] Step 1: Apply 1.5 mm thick Zr 64.13 Cu 15.75 Ni 10.12 Al 10 The alloy sheet was polished with 400-mesh, 600-mesh, 800-mesh, 1000-mesh and 1200-mesh silicon carbide sandpaper in sequence, and ultrasonically cleaned with acetone, ethanol and deionized water in sequence.

[0028] Step 2: Measure 900 ml of anhydrous acetic acid and 100 ml of propionic acid solution in a fume hood and mix to form a solution. Then measure 7 ml of perchloric acid and slowly add it into the above solution under stirring (the above raw materials are all of analytical grade).

[0029] Step 3: Put 1 cm 2 Area of Zr 64.13 Cu 15.75 Ni 10.12 Al 10 alloy sheet, and 3 cm 2 The pure titanium sheet was immersed in the electrolyte so...

Embodiment 2

[0033] This example adopts this electrochemical polishing electrolyte and surface polishing technology, to Zr 62.5 Cu 22.5 Fe 5 Al 10 The (atomic ratio) alloy surface is polished to give it a specular luster and to obtain very little surface roughness.

[0034] Step 1: Apply 1.5 mm thick Zr 62.5 Cu 22.5 Fe 5 Al 10 The alloy sheet was polished with 400 mesh, 600 mesh, 800 mesh, 1000 mesh and 1200 mesh silicon carbide sandpaper in sequence, and ultrasonically cleaned with acetone, absolute ethanol and deionized water in sequence.

[0035] Step 2: Measure 900 ml of anhydrous acetic acid and 100 ml of propionic acid solution in a fume hood and mix to form a solution. Then measure 6 ml of perchloric acid and slowly add it into the above solution under stirring (the above raw materials are all of analytical grade).

[0036] Step 3: Put 1 cm 2 Area of Zr 62.5 Cu 22.5 Fe 5 Al 10 alloy sheet, and 3 cm 2 The pure titanium sheet was immersed in the electrolyte, the temper...

Embodiment 3

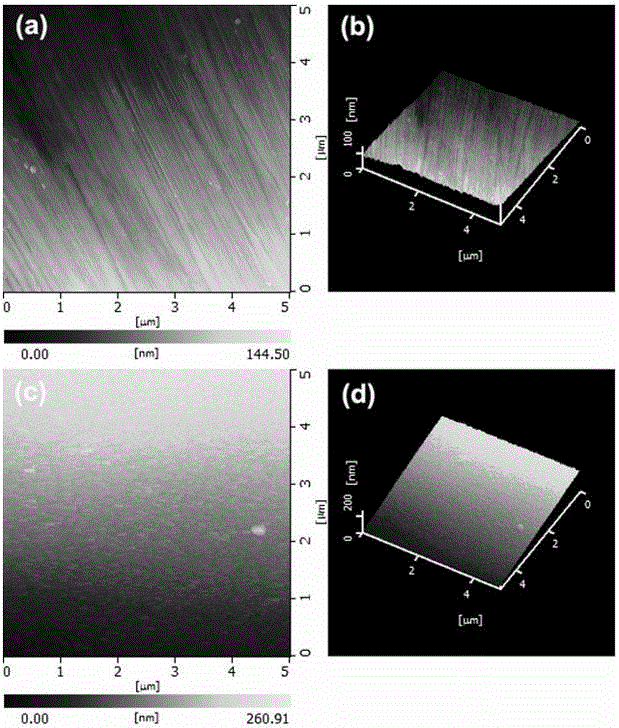

[0040] This example adopts this electrochemical polishing electrolyte and surface polishing technology, to Zr 46 Cu 37.6 Ag 8.4 Al 8 The (atomic ratio) alloy surface is polished to give it a specular luster and to obtain very little surface roughness.

[0041] Step 1: Apply 1.5 mm thick Zr 46 Cu 37.6 Ag 8.4 Al 8The alloy sheet was polished with 400 mesh, 600 mesh, 800 mesh, 1000 mesh and 1200 mesh silicon carbide sandpaper in sequence, and ultrasonically cleaned with acetone, absolute ethanol and deionized water in sequence.

[0042] Step 2: Measure 900 ml of anhydrous acetic acid and 100 ml of propionic acid solution in a fume hood and mix to form a solution. Then measure 5 ml of perchloric acid and slowly add it into the above solution under stirring (the above raw materials are all of analytical grade).

[0043] Step 3: Put 1 cm 2 Area of Zr 46 Cu 37.6 Ag 8.4 al 8 alloy sheet, and 3 cm 2 The pure titanium sheet was immersed in the electrolyte solution, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com