A combined elliptical cross-section member and its processing method

A processing method, elliptical technology, applied in the direction of truss structures, joists, girders, etc., can solve the problems of increasing steel consumption and structural weight, unfavorable structural stability and safety, and increasing the overall component cross-section. Achieve the effects of shortening the processing cycle, easily ensuring the welding quality, and reducing the weight of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

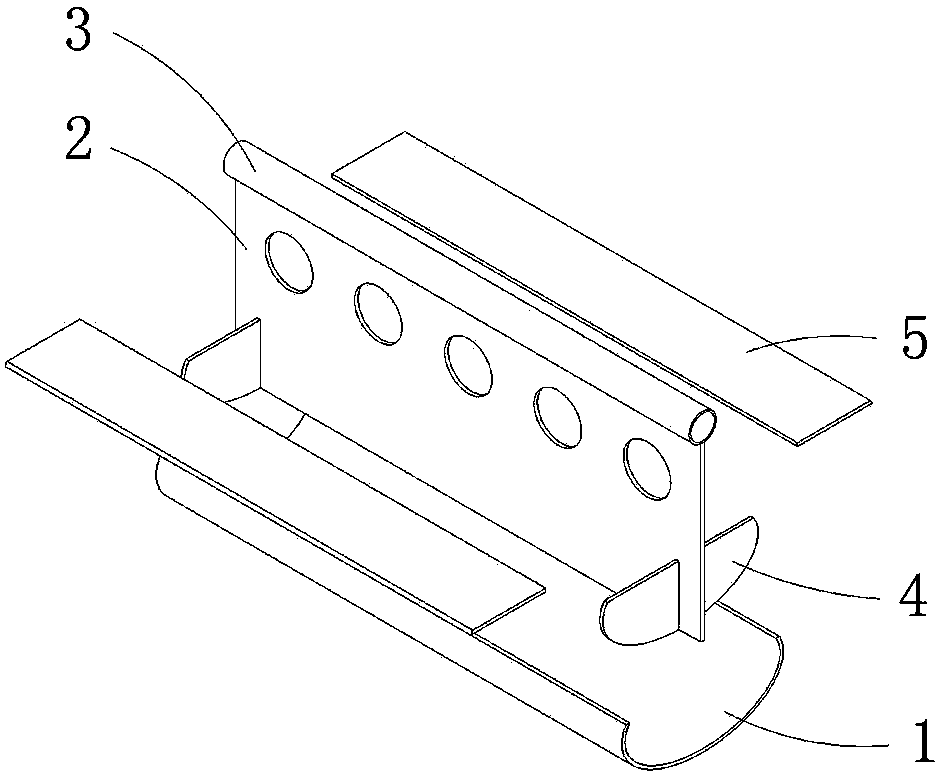

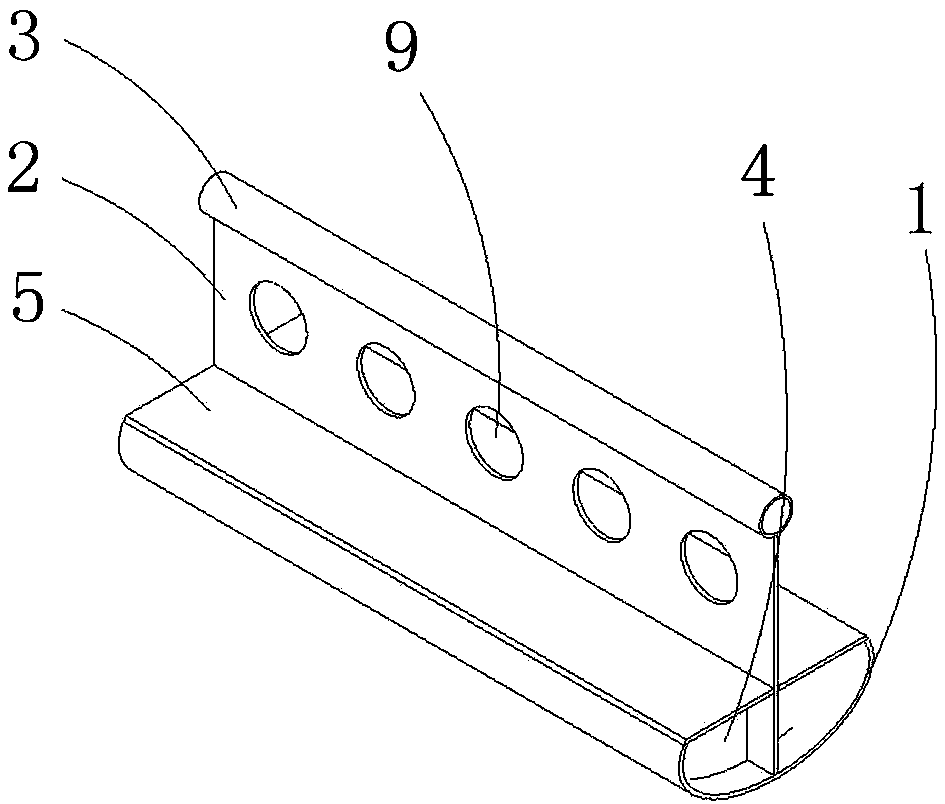

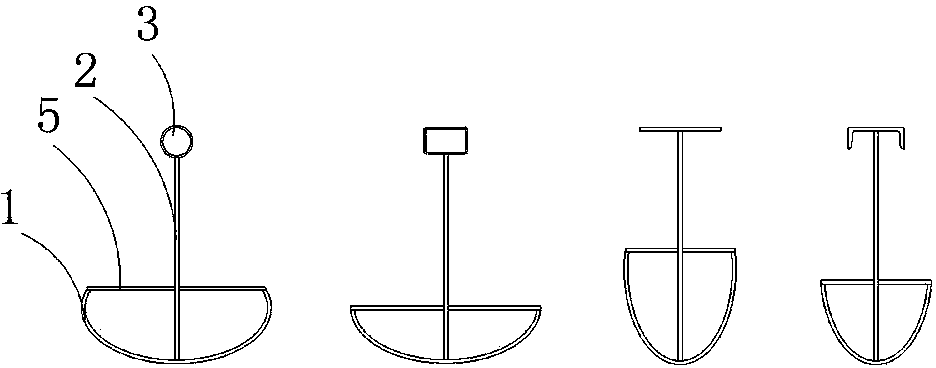

[0051] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, a combined elliptical cross-section member includes a bottom support 1 and a web 2, the upper part of the web 2 is provided with a connector 3, and the lower part of the web 2 is arranged in the bottom support 1, so The bottom support 1 and the web 2 are fixed by an assembly mechanism, the assembly mechanism includes a transverse reinforcement plate 4, and the two ends of the bottom of the web 2 are inserted with transverse reinforcement plates 4 vertically distributed thereto. , the bottom side wall of the transverse reinforcing plate 4 is matched with the inner wall of the bottom brace 1, and the bottom brace 1, the transverse reinforcing plate 4 and the web 2 are encapsulated by the sealing plate 5; or, the The assembling mechanism comprises an upper longitudinal reinforcing plate 6 and an upper transverse reinforcing plate 7, the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com