Construction method of indoor anti-static shielding mesh system

A construction method and shielding mesh technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of long construction period, complicated operation, high project cost, etc., and achieve shortened construction period, simple construction process and long construction period. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

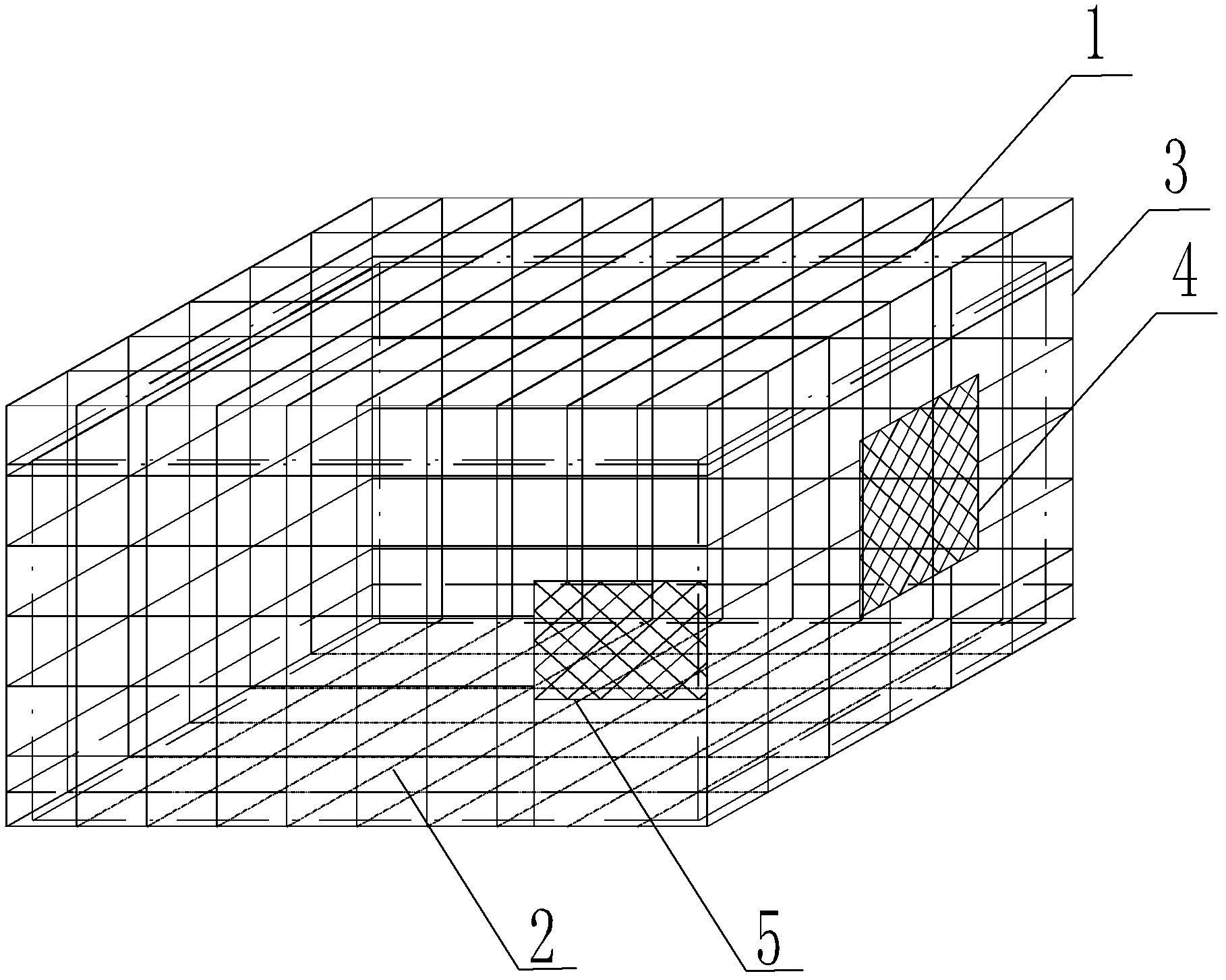

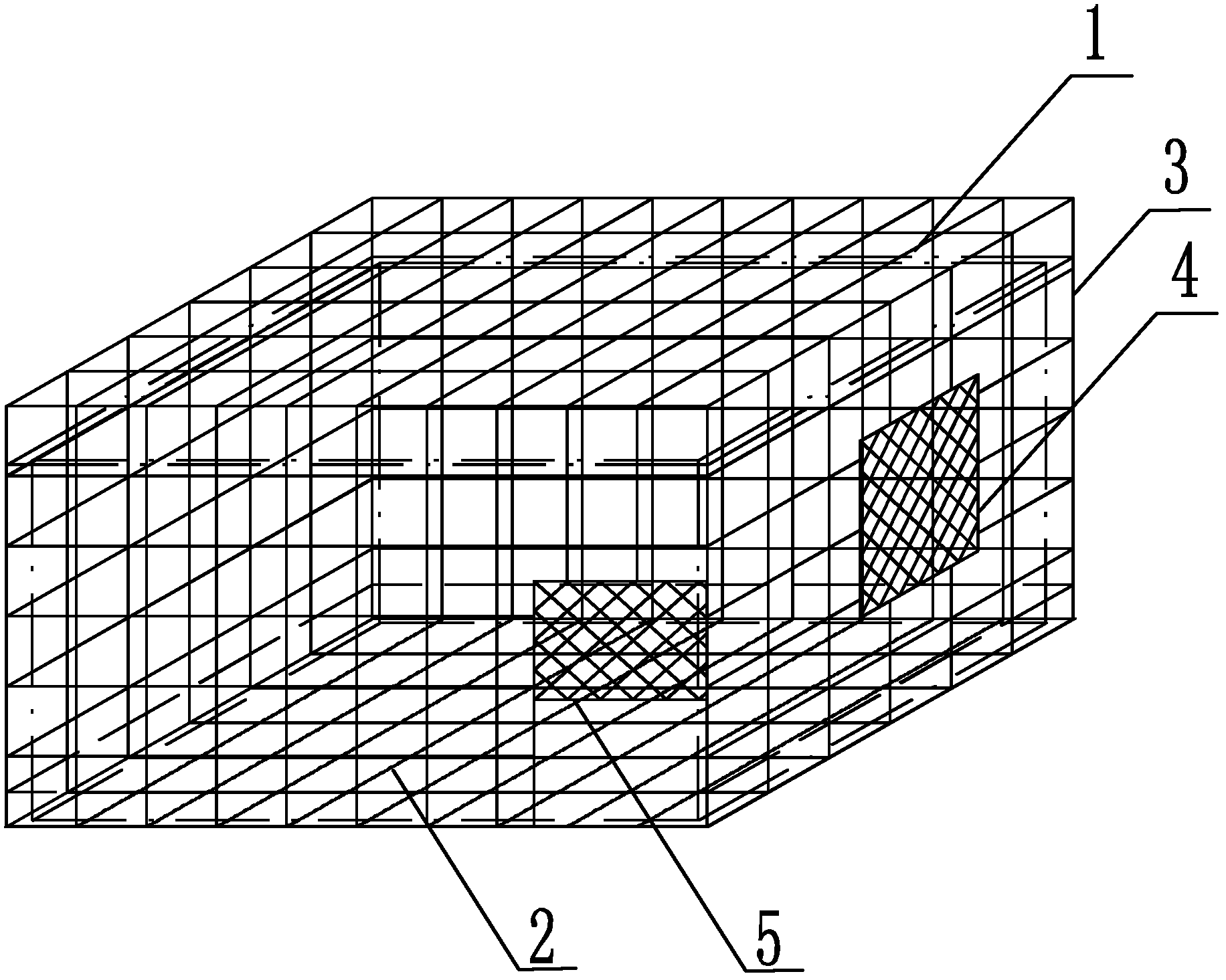

[0037] like figure 1The anti-static shielding net shown is composed of roof surface metal grid 1, ground shielding grid 2, wall shielding grid 3, window aluminum alloy grid 4 and metal door 5, which are welded by φ8mm galvanized round steel Composition, the above grids are all square. The side length of the metal grid 1 on the roof surface, the shielding grid 2 on the ground, and the shielding grid 3 on the wall is 600mm×600mm. The size of the 4 side lengths of the window aluminum alloy grid is 80mm×80mm.

[0038] The construction method of the indoor antistatic shielding net system of the present invention specifically comprises the following steps:

[0039] (1) Install the shielding grid on the roof surface: the anti-static shielding grid on the roof surface is located above the ceiling 6, and the grid suspenders are made of φ8mm galvanized round steel, which are fixed with high-strength self-tapping screws for installing the keel on the ceiling suspenders on the roof surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com