Cutting-free self-forming method of micro plane parts

A self-forming, planar technology, applied in the field of inertial confinement fusion research, achieves the effects of low cost, wide application range and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

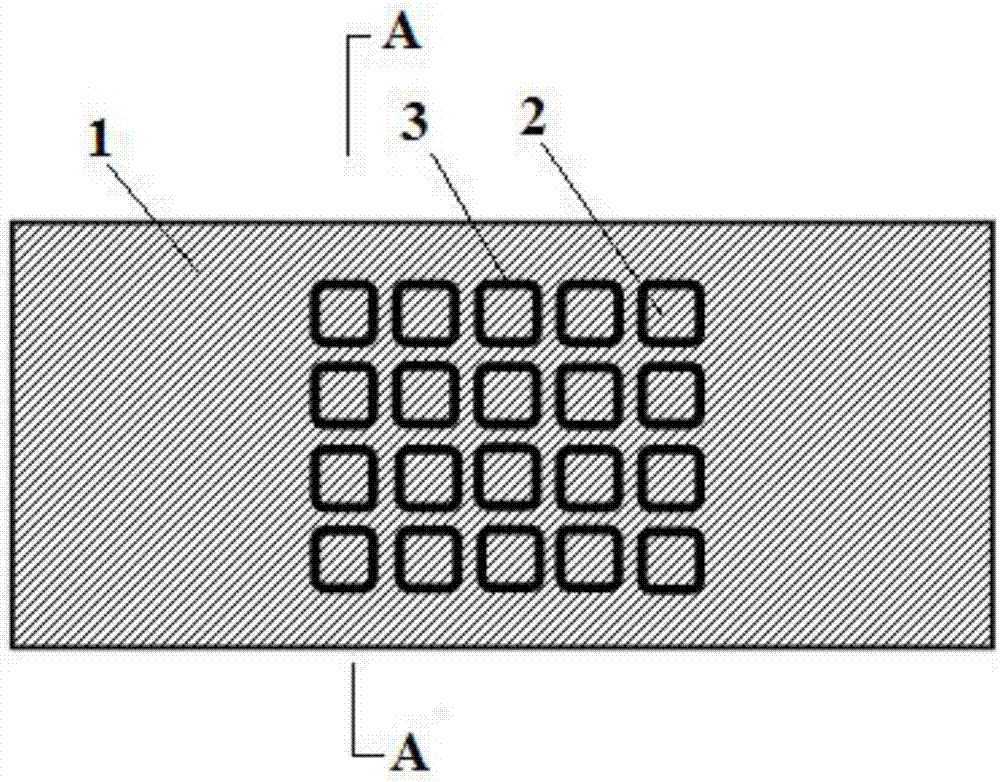

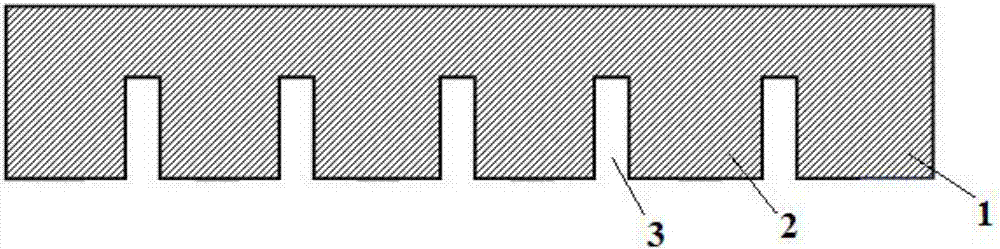

[0025] Specific Embodiment 1: This embodiment is a self-forming method without cutting of tiny planar parts, which is specifically completed according to the following steps:

[0026] 1. Template preparation: on the Si substrate of the prefabricated pattern, a CsI release agent with a thickness of 90nm to 110nm is prepared by thermal evaporation coating technology, that is, a template plated with a release agent is obtained, and the template is stored in a vacuum or in a dry environment; the prefabricated The patterned Si substrate includes edge protrusions, graphic protrusions and grooves. The graphic protrusions are prepared according to the planar structure shape of tiny planar parts, the width of the grooves is 10 μm to 30 μm, and the width of the grooves is The aspect ratio is not less than 1, and the steepness of the groove is 90°±5°;

[0027] 2. Preparation of micro-planar part material film: adopt deposition method to prepare micro-planar part material film on the temp...

specific Embodiment approach 2

[0031] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the Si substrate of the prefabricated pattern described in step 1 is prepared according to the following method: 1., substrate cleaning: adopting a thickness of 250 μm monocrystalline silicon As the substrate, and the surface roughness of the substrate is Ra<5nm, the substrate is cleaned and then dried to obtain the cleaned substrate; ②, template processing: photolithographic pattern replication and Si deep reactive ion etching In the engraving process, the substrate is processed into a template, the photoresist and chips are removed, and after cleaning, it is blown dry with nitrogen to obtain a pre-patterned Si substrate; the template includes edge protrusions, pattern protrusions and grooves, and the The graphic protrusion is prepared according to the structural shape of the tiny planar part. The width of the groove is 10 μm to 30 μm, the aspect ratio of the groove is not less than 1, the ste...

specific Embodiment approach 3

[0032] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the deposition method described in step 2 is a magnetron sputtering method, a reactive magnetron sputtering method or a glow discharge plasma method; When using simple metal materials to make tiny planar parts, choose magnetron sputtering method for deposition; when using metal compounds to make tiny planar parts, choose reactive magnetron sputtering method for deposition; when using CH polymer materials to make tiny planar parts , select the glow discharge plasma method. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com