Device for solving valve faults in space division system and operation method

An air separation system and valve technology, which is applied to the valve operation/release device, valve device, valve details, etc., can solve the problems that cannot be effectively solved, does not have replacement conditions, and has a long order cycle, and achieves novel, The effect of reducing the downtime rate and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

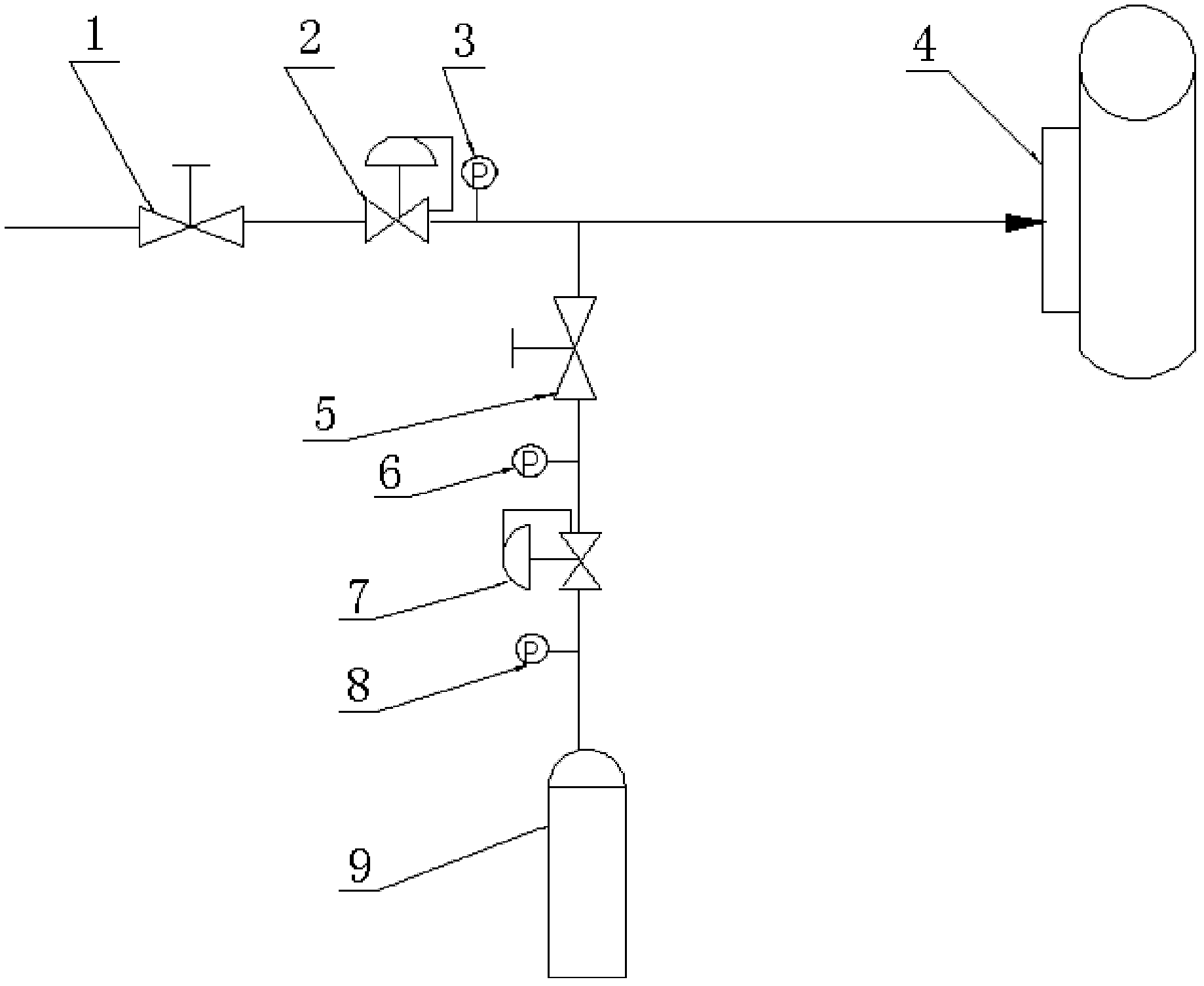

[0022] Depend on figure 1 It can be seen from the shown structure that the device for solving valve failures in the air separation system includes a first shut-off valve 1, a first pressure reducing valve 2, a first pressure gauge 3 and a valve cylinder 4 connected in series in sequence, located between the first pressure gauge 3 and the valve cylinder 4. There is an instrument pipe connected in series between the valve cylinders 4 through a tee, and the instrument pipe connected in series includes a second cut-off valve 5, a second pressure gauge 6, a second pressure reducing valve 7, and a third pressure gauge 8 in series. and an external gas source 9, the second shut-off valve 5 is connected with the first pressure gauge 3 and the valve cylinder 4 through a tee, the external gas source 9 is located at the end of the pipeline, and the external gas source 9 is a high-pressure gas cylinder containing nitrogen gas .

[0023] Using the above device, the operation method for pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com