Method of adhering sensor chips

A sensor chip and silicon chip technology, applied in the direction of instruments, measuring devices, measuring force, etc., can solve problems such as drift, easy creep of fixing glue, and inability to achieve accurate pressure measurement, so as to achieve the effect of avoiding drift and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

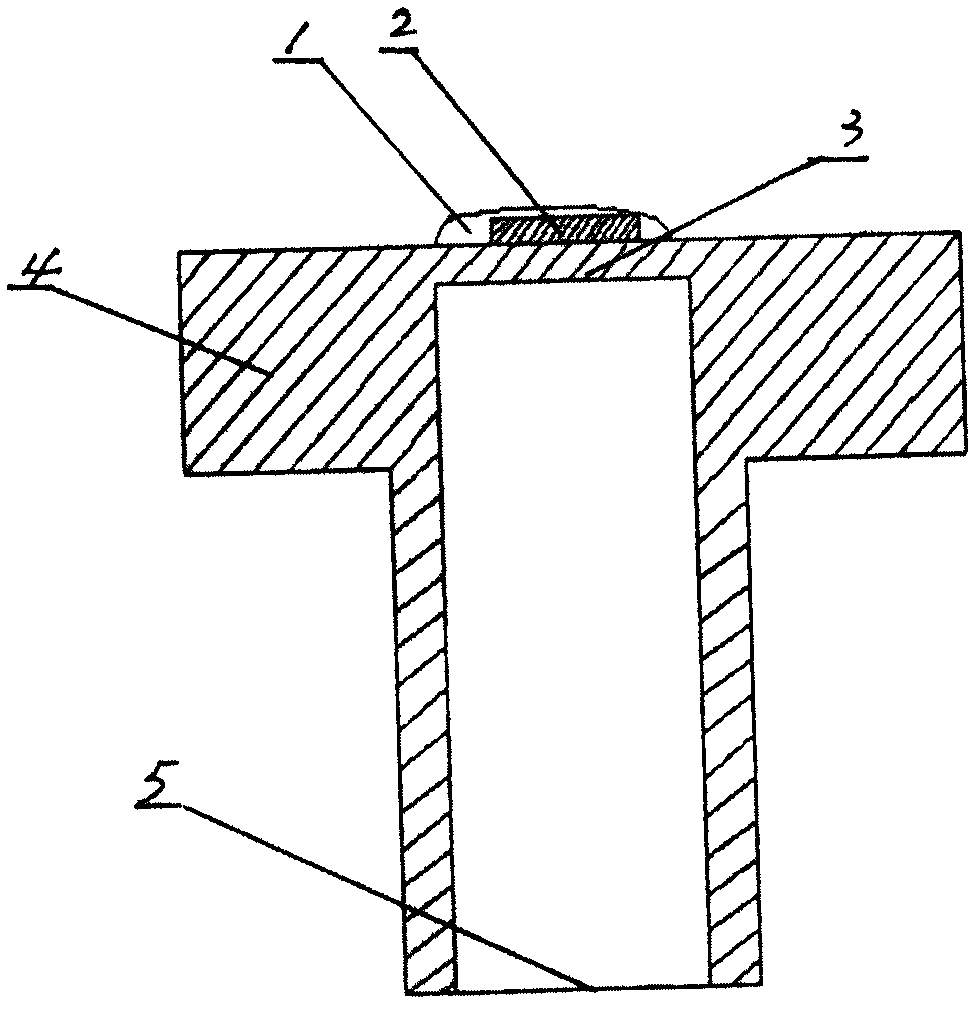

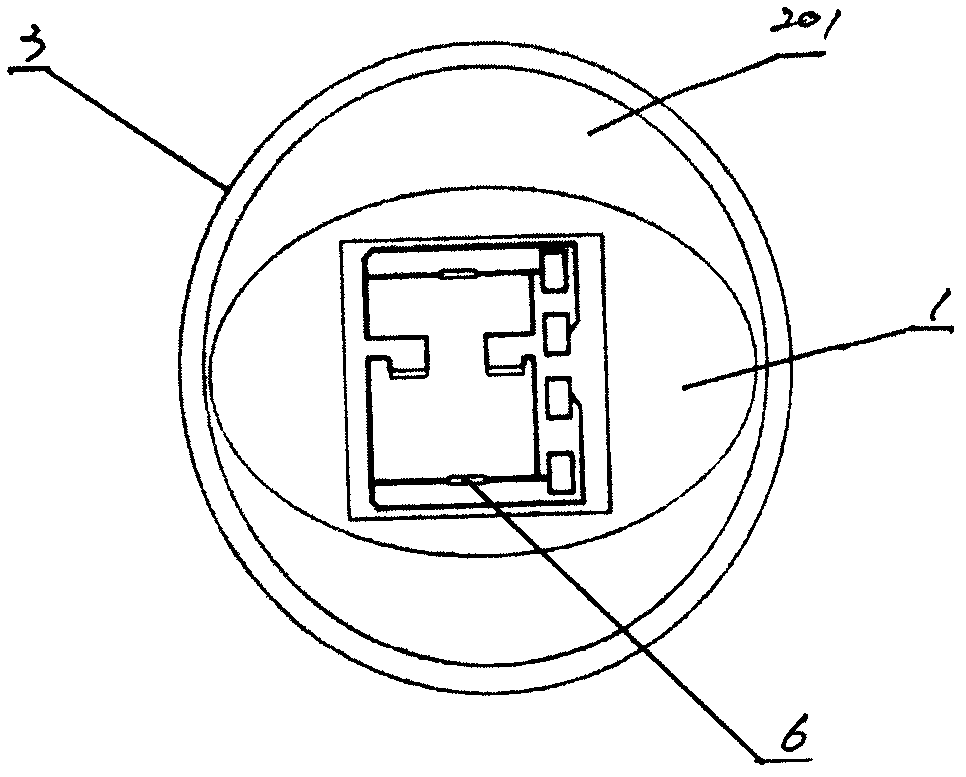

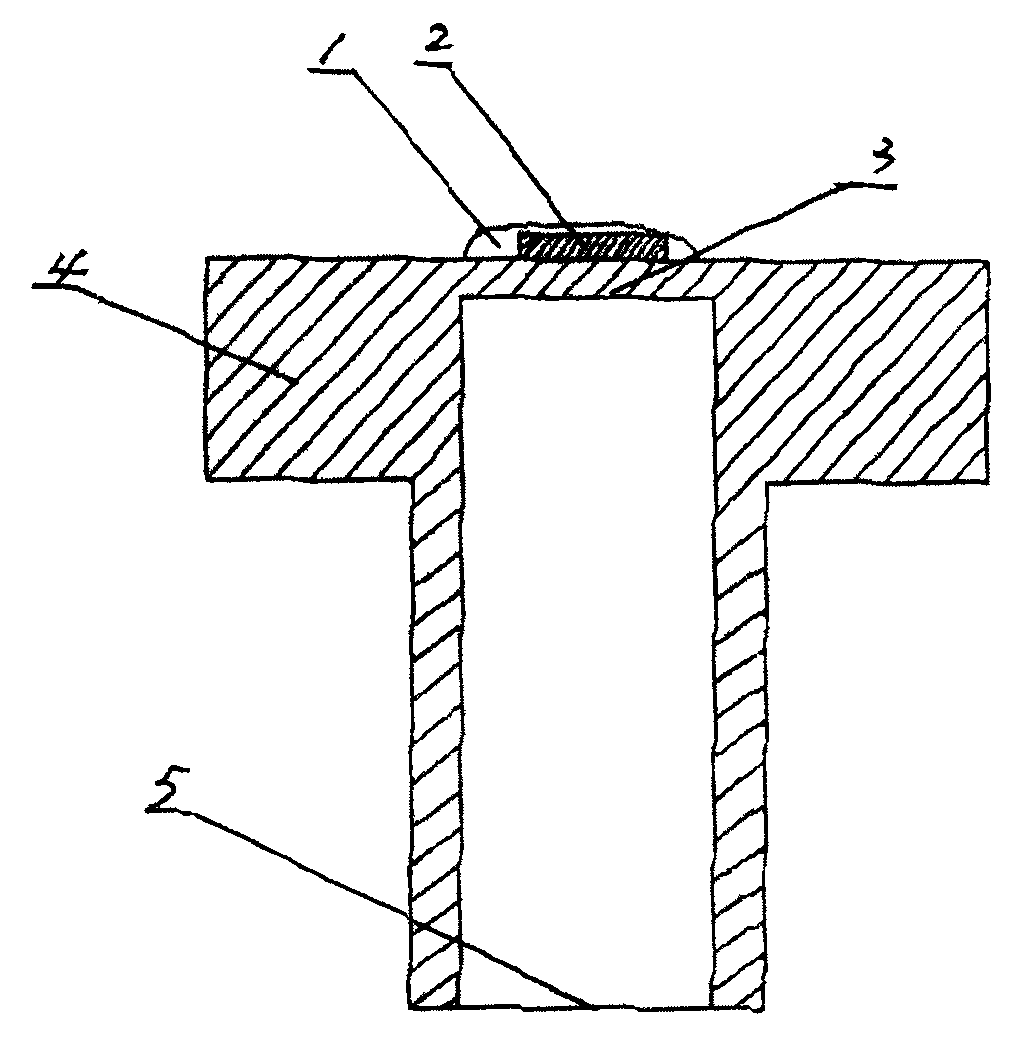

[0018] Such as figure 1 and figure 2 As shown, prepare the metal base and the sensor chip 2 first. The metal base is tubular, one end of which is processed with a back cover for constituting the metal diaphragm 3 , and the outer boss 4 is machined in the outer circle of the end with the back cover. The other end of the metal base is open to form the port 5 . The sensor chip 2 includes a silicon chip 201 on which four strain gauges 6 are integrated, and the four strain gauges are connected to form a Wheatstone bridge through metallization deposition.

[0019] Then, the metal diaphragm 3 is subjected to shot blasting treatment with a shot blasting machine, so that the outer surface of the metal diaphragm 3 forms a rough surface.

[0020] Afterwards, the glass powder is printed on the rough surface of the metal diaphragm 3 by using a screen printing machine.

[0021] Afterwards, put the metal base with the glass powder into a tube furnace at a temperature of 450°C for heatin...

Embodiment 2

[0024] Such as figure 1 and figure 2 As shown, prepare the metal base and the sensor chip 2 first. The metal base is tubular, one end of which is processed with a back cover for constituting the metal diaphragm 3 , and the outer boss 4 is machined in the outer circle of the end with the back cover. The other end of the metal base is open to form the port 5 . The sensor chip 2 includes a silicon chip 201 on which four strain gauges 6 are integrated, and the four strain gauges are connected to form a Wheatstone bridge through metallization deposition.

[0025] Then, the metal diaphragm 3 is subjected to shot blasting treatment with a shot blasting machine, so that the outer surface of the metal diaphragm 3 forms a rough surface.

[0026] Afterwards, the glass powder is printed on the rough surface of the metal diaphragm 3 by using a screen printing machine.

[0027] Afterwards, put the metal base with the glass powder in a tube furnace with a temperature of 500° C. for heat...

Embodiment 3

[0030] Such as figure 1 and figure 2 As shown, prepare the metal base and the sensor chip 2 first. The metal base is tubular, one end of which is processed with a back cover for constituting the metal diaphragm 3 , and the outer boss 4 is machined in the outer circle of the end with the back cover. The other end of the metal base is open to form the port 5 . The sensor chip 2 includes a silicon chip 201 on which four strain gauges 6 are integrated, and the four strain gauges are connected to form a Wheatstone bridge through metallization deposition.

[0031] Then, the metal diaphragm 3 is subjected to shot blasting treatment with a shot blasting machine, so that the outer surface of the metal diaphragm 3 forms a rough surface.

[0032] Afterwards, the glass powder is printed on the rough surface of the metal diaphragm 3 by using a screen printing machine.

[0033] Afterwards, putting the metal base with the glass powder into a tube furnace with a temperature of 550° C. is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com