Double-path power negative feedback system for laser processing equipment

A laser processing and negative feedback technology, applied in laser welding equipment, metal processing equipment, lasers, etc., can solve problems such as restricting the laser output stability of processing points, improve stability and laser power control accuracy, and improve laser processing quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described below in combination with specific embodiments and with reference to the accompanying drawings.

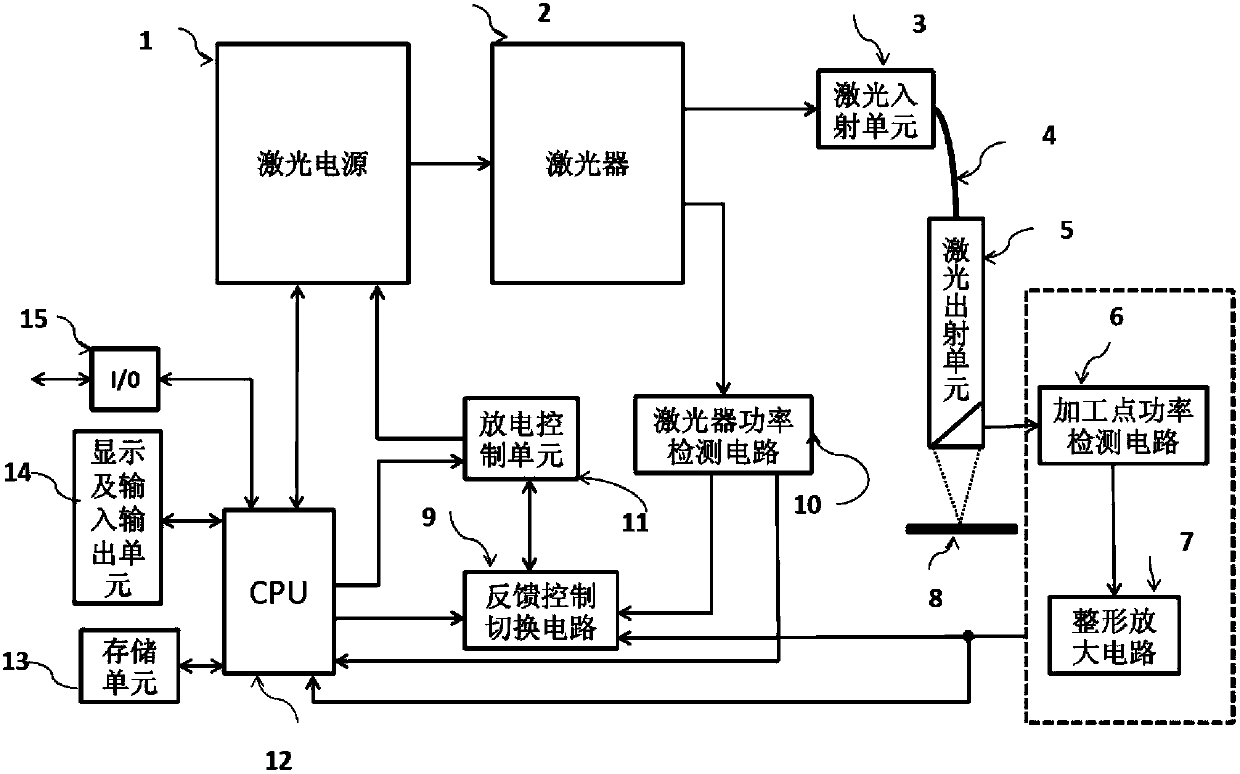

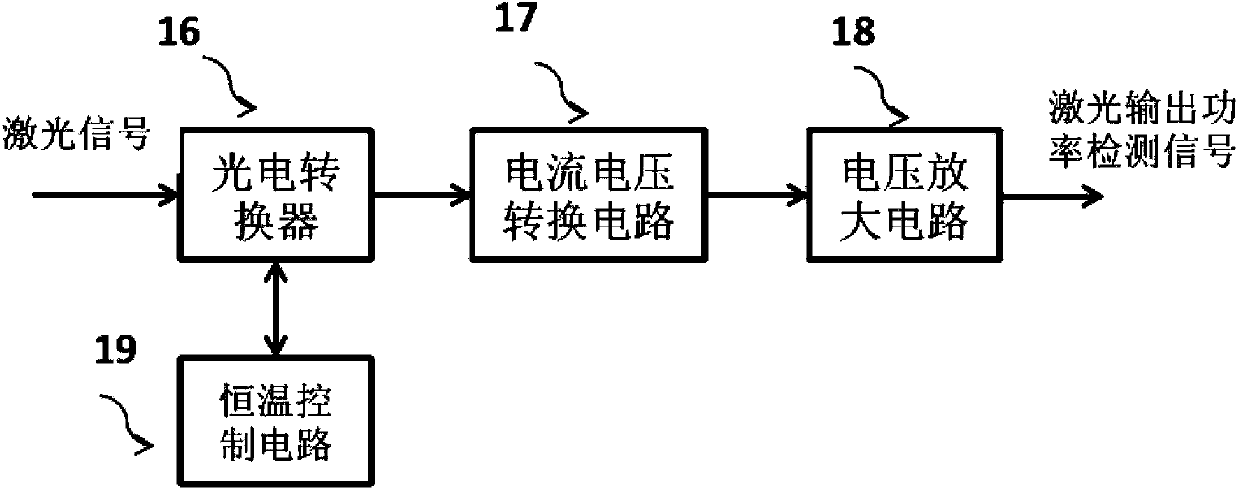

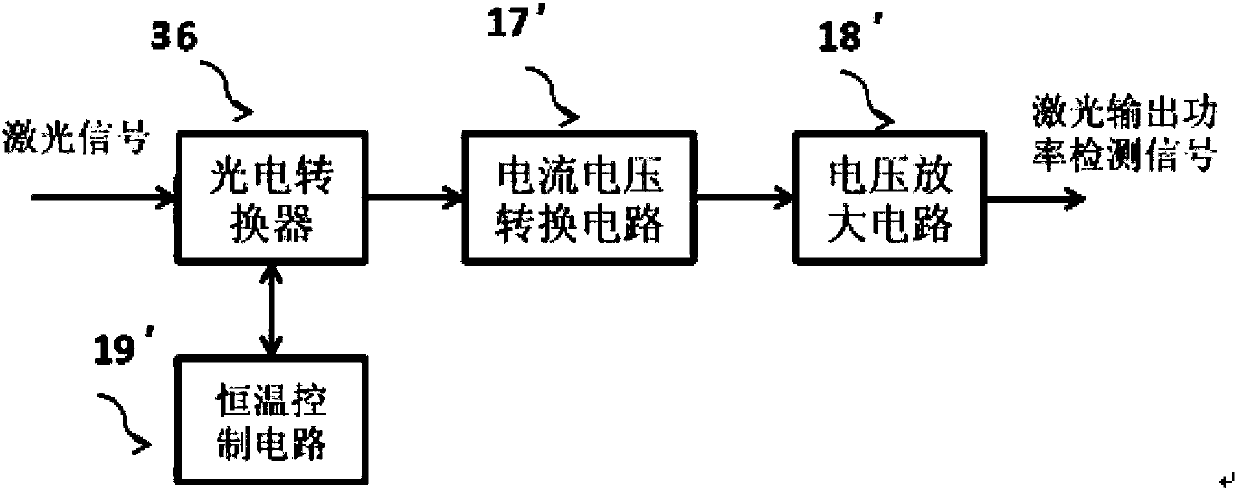

[0037] a kind of like Figure 1~6 The shown dual power negative feedback system for laser welding machines includes a closed loop consisting of a laser 2, a laser output power detection circuit 10 arranged at the output end of the laser 2, a negative feedback control circuit 9, and a laser power supply control circuit connected in sequence Negative feedback system, laser output power detection circuit 10 is also connected with laser power supply control circuit, laser power supply control circuit includes laser power supply 1, CPU12 and discharge control unit 11 that are connected with laser power supply 1 respectively, CPU12 is the CPU that comprises high-speed DSP, its Peripheral circuits include input / output (I / O) interface 15, display and input / output unit 14, and storage unit 13. CPU 12 is used for data processing and system cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com