High-speed two-way permanent-magnetic reset proportion electromagnet

A proportional electromagnet and electromagnet technology, applied in the field of electromagnets, can solve the problems of insufficiency, slow system response, large quality of moving iron, etc., so as to improve the spool position control accuracy, improve the system response bandwidth, and improve the economy and efficiency. The effect of social benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

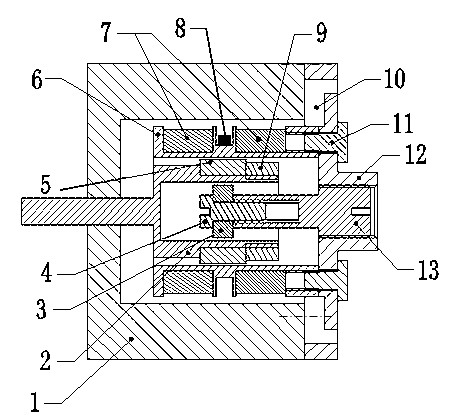

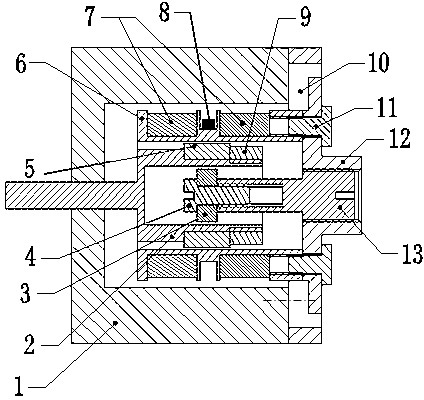

[0017] Attached below figure 1 And embodiment the present invention is described further.

[0018] The present invention includes an electromagnet shell 1, a cylindrical push rod 2, a permanent magnet inner ring 3, a fixing screw 4, a permanent magnet outer ring 5, a coil frame 6, an electromagnetic coil 7, a linear Hall sensor 8, a fixing nut 9, and a lead hole 10. Non-magnetic screw 11, rear end cover 12 and zero adjustment screw 13; inside the electromagnet housing 1, there is a coaxial coil frame 6, and the outer surface of the coil frame 6 is provided with three annular grooves, and the linear Hall sensor 8 is glued to it. The junction is in the middle annular groove, and two electromagnetic coils 7 are reversely wound and connected in series in the annular grooves on both sides. One side of the coil bobbin 6 is fixed to the rear end cover 12 through a non-magnetic screw 11; the inside of the coil bobbin 6 The cylinder push rod 2 is coaxially installed, and the rod end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com