Segmented iron core

A technology of iron core and iron core column, which is applied in the direction of transformer/inductor magnetic core, inductance/transformer/magnet manufacturing, electrical components, etc. It can solve the problems of transformer coil burnout, easy heating of coil parts, coil burnout, etc., and achieve the best results Good, the method is simple and reliable, and the effect of increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings.

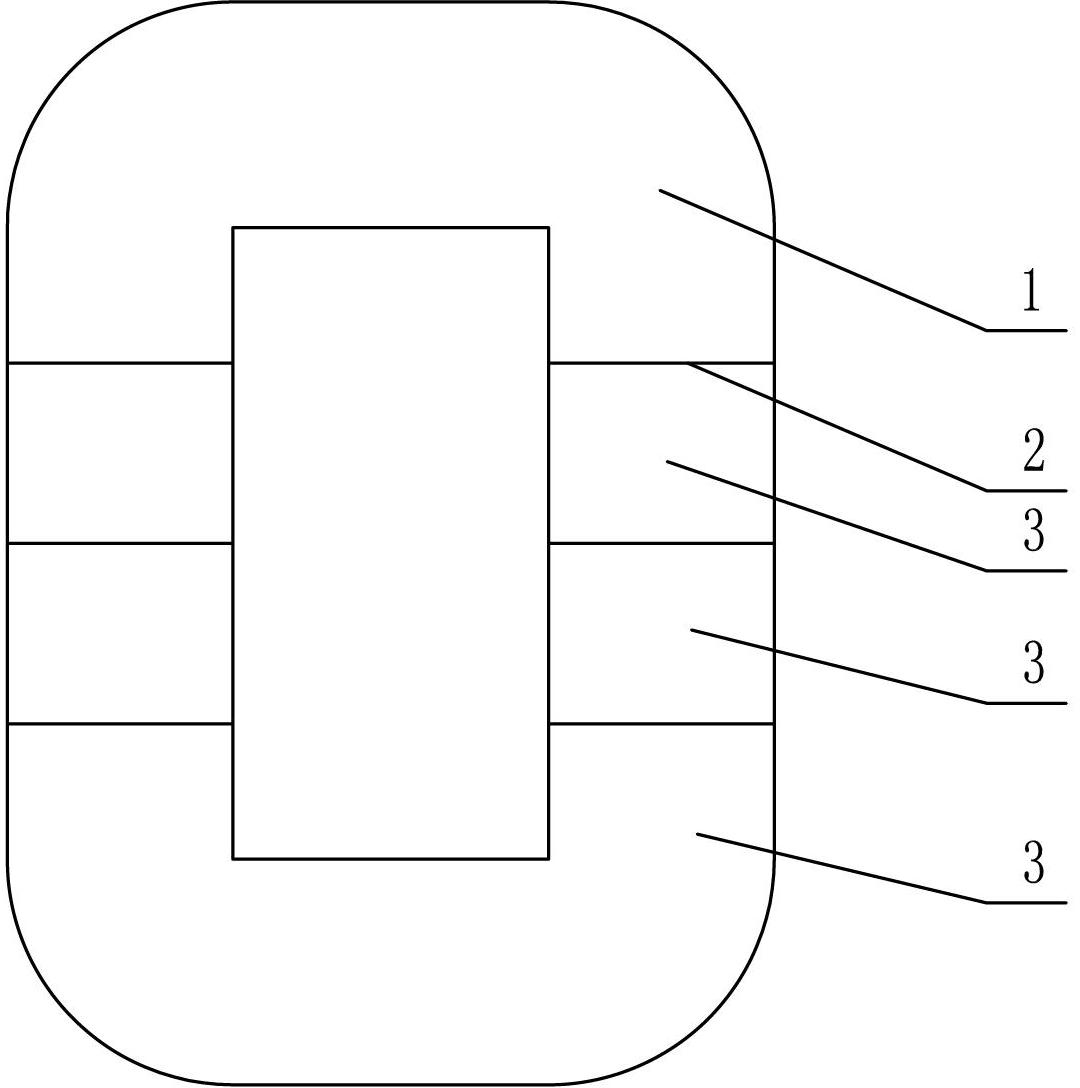

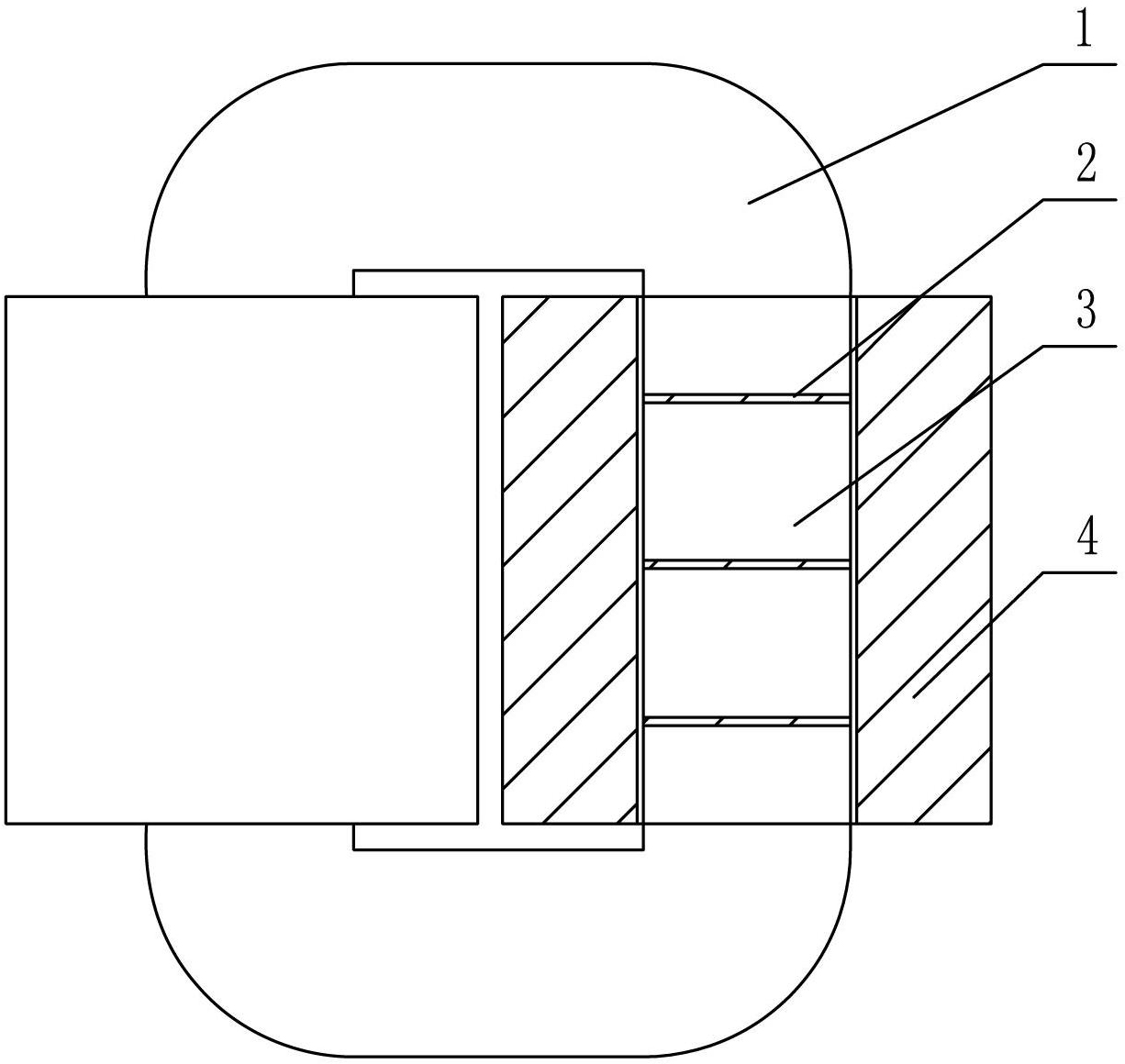

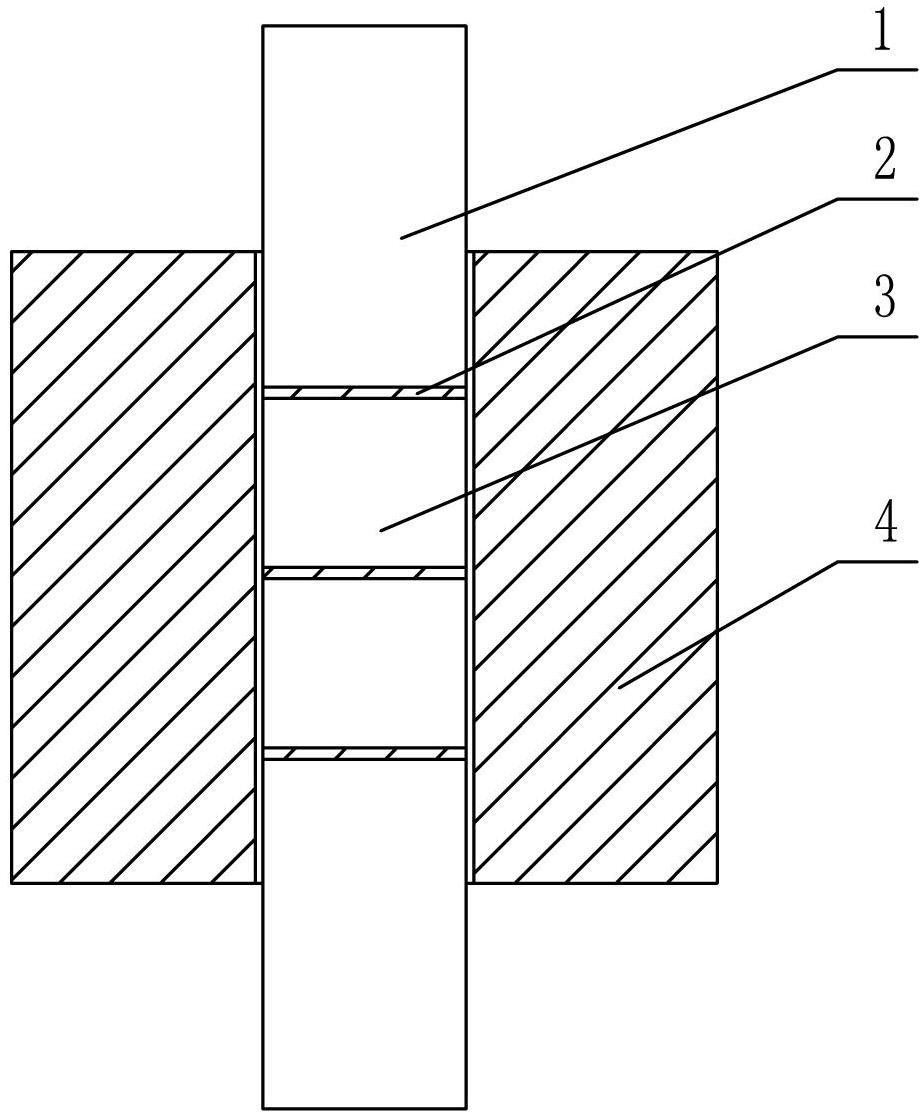

[0015] Such as Figure 1 ~ Figure 3 Shown: Segmented iron core includes iron core body (1), air gap (2), iron core segment (3), coil (4) and so on.

[0016] Such as figure 1 As shown, the present invention includes a rectangular iron core body (1), and three air gaps (2) are respectively arranged on the iron core columns on the left and right sides of the iron core body (1), separating the iron core body (1) into Six sections of iron core section (3);

[0017] The air gap (2) is set on the iron core column where the coil (4) is wound, and the air gap (2) is set on the cutting end surface of the iron core column.

[0018] Such as figure 1 As shown, the present invention divides the iron core body into multi-section iron core segments by increasing the number of cuts on the iron core column, that is, increasing the number of air gaps; figure 2 , image 3 As shown, there a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com